Manufacturing method of 3D storage device and chemical vapor deposition method of adhesive film

A technology of chemical vapor deposition and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, gaseous chemical plating, electrical components, etc. It can solve the problems that the precursor gas is difficult to reach the bottom of the deposition channel, device failure, etc., and achieve improved electrical performance , Improve adhesion, increase the effect of step coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in more detail below with reference to the accompanying drawings. In the various figures, the same elements are provided with similar labels.

[0029] If in order to describe the situation directly on another layer, another area, the text will use "directly on...

[0030] In this application, the term "semiconductor structure" refers to the entire semiconductor structure formed in the various steps of manufacturing a memory device

[0031] The present invention may be embodied in various forms, some examples of which will be described below.

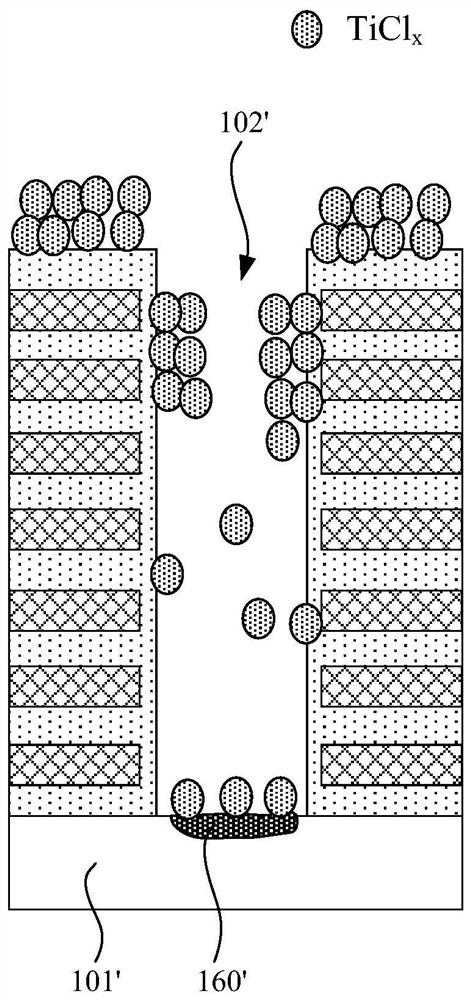

[0032] FIG. 1 shows a schematic diagram of a prior art adhesion film deposition method.

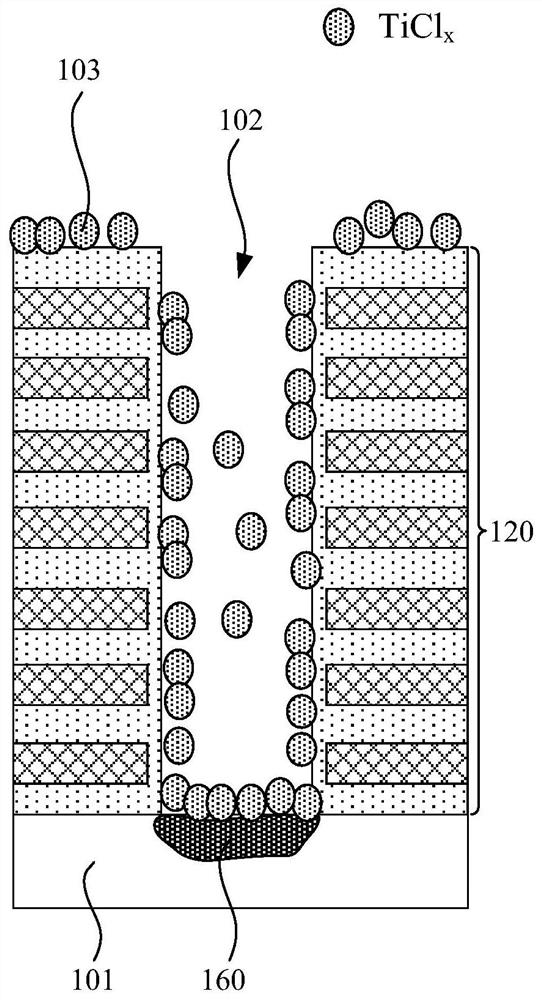

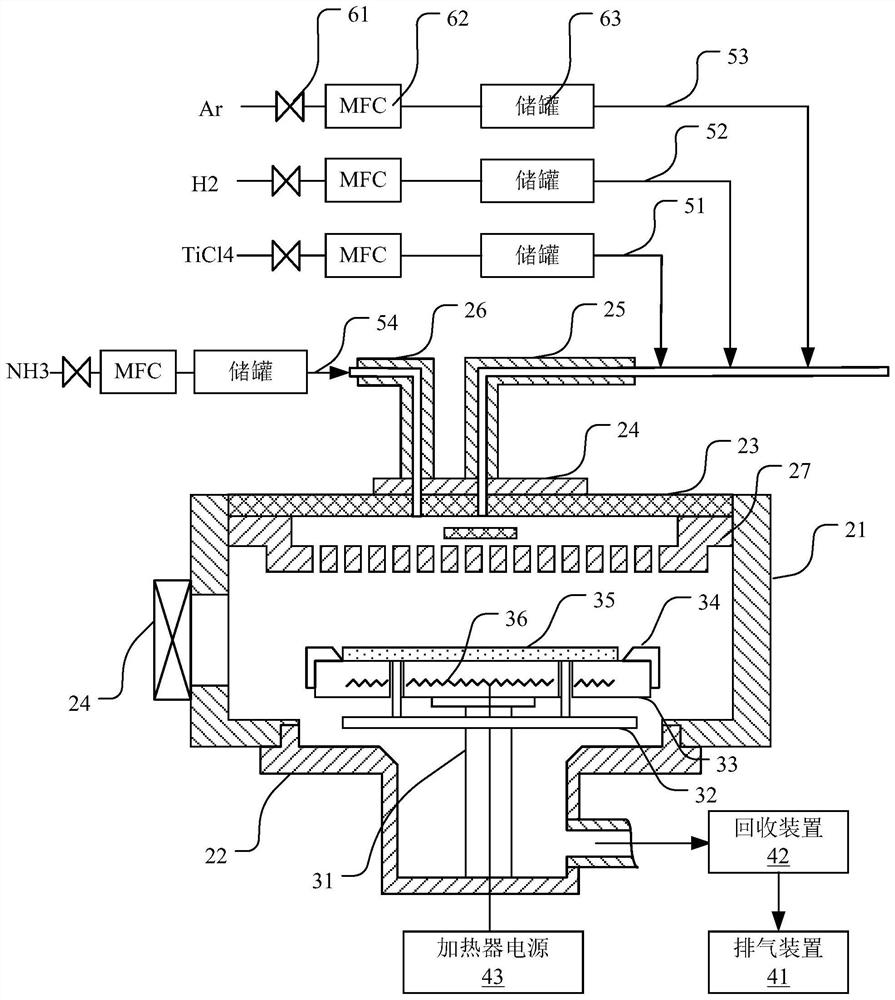

[0033] An adhesive film is formed on a predetermined surface of the semiconductor structure using a chemical vapor deposition process. The deposition method includes

[0036] In a 3D memory device, a TiN film needs to be used as an adhesive film for a metal conductive structure. This is due to deposition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com