Environment-friendly warm-heading oil and preparation method thereof

An environmentally friendly and warm-up technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of irregular workpiece forming, shortened life of abrasive tools, damage of molded abrasive tools, etc., to reduce roughness, improve service life, and reduce accumulation. effect of carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1: An environment-friendly warm pier oil, the components included and their corresponding qualities are shown in Table 1, and are prepared through the following steps:

[0058] Step 1: First, the temperature of the base oil (mineral oil) is raised to 75° C., while stirring at a speed of 100 rpm, and then the phosphate ester and the base oil are mixed at the same speed for 10 minutes to obtain the first mixed oil;

[0059] Step 2, mixing the oily agent with the first mixed oil for 5 minutes to obtain the second mixed oil;

[0060] Step 3, extruding calcium sulfonate and the second mixed oil for 5 minutes to obtain the third mixed oil;

[0061] Step 4, the polymer ester is mixed with the third mixed oil for 5 minutes to obtain the fourth mixed oil;

[0062] Step 5, trimethylolpropane triacrylic acid and the fourth mixed oil are mixed for 5 minutes to obtain the fifth mixed oil;

[0063] Step 6, mix the anti-foaming agent with the fifth mixed oil for 5 minutes...

Embodiment 2-5

[0066] Example 2-5: An environment-friendly warm oil, the difference from Example 1 is that the components included and their corresponding qualities are shown in Table 1.

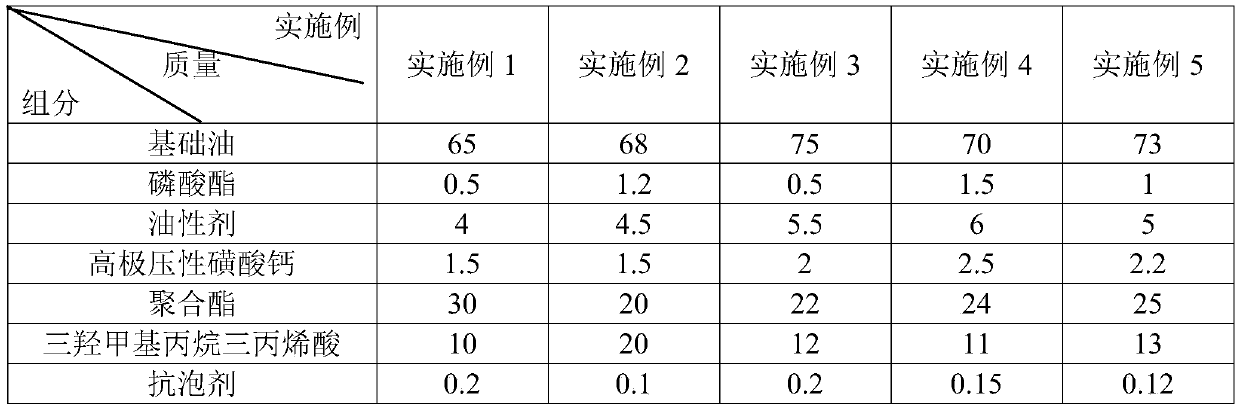

[0067] Components included in table 1 embodiment 1-5 and their corresponding quality

[0068]

[0069] Among them, the oily agent is vulcanized lard CR-T3510; the high extreme pressure calcium sulfonate is high base value synthetic calcium sulfonate T106; the polymer ester is Lubrizol GY-59; the antifoaming agent is polydimethyl silicone oil.

Embodiment 6

[0070] Embodiment 6: An environment-friendly warm pier oil, the difference from Embodiment 1 is that the vulcanized lard is vulcanized lard CR-T3509.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com