Method for preparing low-free p-phenylene diisocyanate prepolymer

A technology of p-phenylene diisocyanate and prepolymer, which is applied in the field of prepolymer preparation, and can solve problems such as multiple impurities, product discoloration, and increased economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

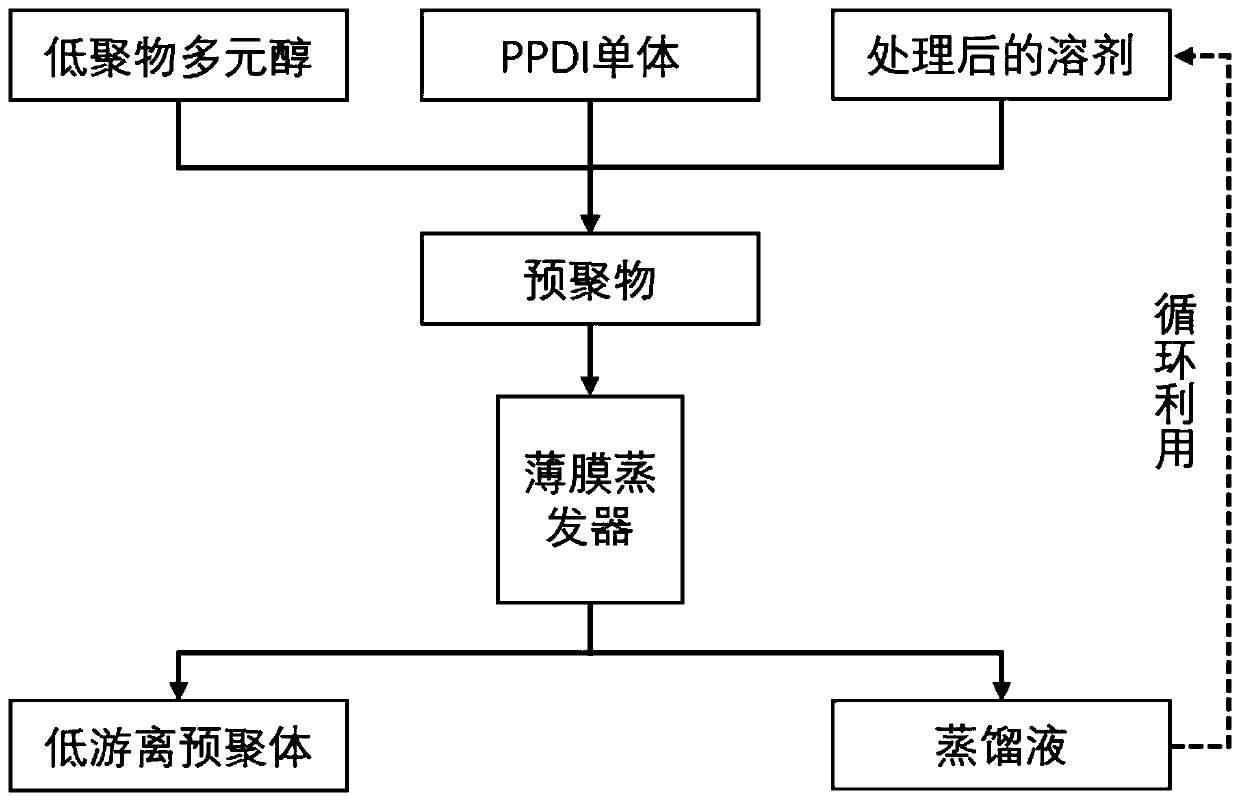

[0029] figure 1 A schematic flow diagram for the preparation of low free p-phenylene diisocyanate prepolymer provided by the present invention.

[0030] The invention mixes dehydrated polyalcohol, p-phenylene diisocyanate and a single solvent, reacts at 60-70 DEG C, and processes the obtained reaction product in a thin-film evaporator to obtain the treated solvent. The anhydrous polyol and p-phenylene diisocyanate are solutes. In the present invention, the mass ratio of the total mass of the dehydrated polyol and p-phenylene diisocyanate to the single solvent is 1:5 to 1:100, and the mass ratio of p-phenylene diisocyanate and p-phenylene diisocyanate is 10: 1~30:1; In specific embodiment, the substance ratio of described p-phenylene diisocyanate and dehydrated polyol is 20:1; The total mass of described dehydrated polyol and p-phenylene diisocyanate and the mass of described single solvent The ratio is 9:1.

[0031]The boiling point of the single solvent at normal pressure ...

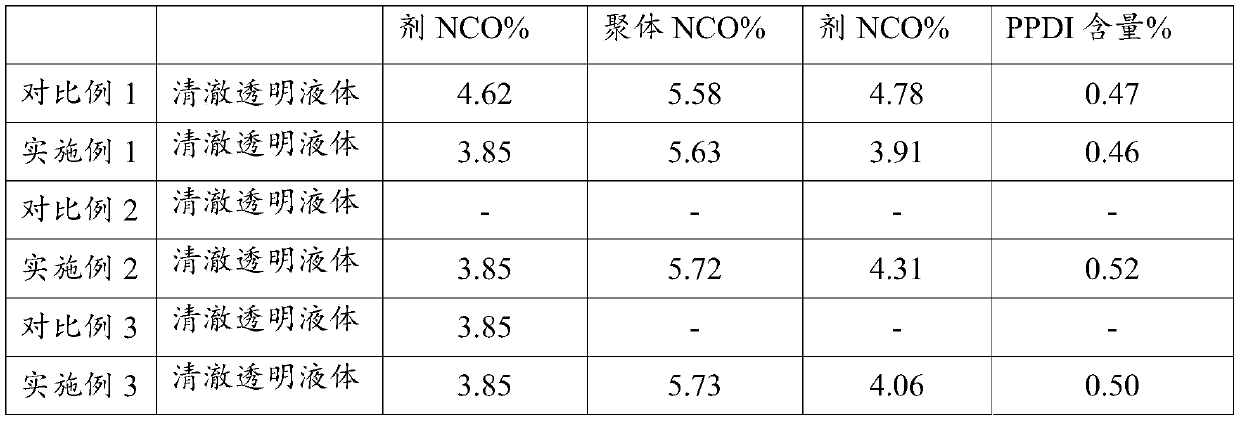

Embodiment 1

[0045] The polyol PTMEG1000 was vacuum dehydrated at 130° C. for 3 hours to remove the moisture in the polyol and set aside. Under a nitrogen atmosphere, at a temperature of 65°C, add 1.16Kg of PPDI to 13.9Kg of diisopropyl adipate solvent and stir evenly to fully dissolve the PPDI, then add 0.36Kg of the above-mentioned polyol into the reactor while stirring, and continue Stir for 3 hours. The molar ratio of PPDI to polyol is 20:1, and the mass ratio of solvent to solute is 9:1. Then add the above mixture into a thin film evaporator, set the internal temperature of the film to 120°C, set the vacuum degree to 40-60Pa, set the condensation temperature to 20-35°C, collect the light component distillate, and measure the NCO value to be 3.85 %.

[0046] Under the protection of nitrogen, pour 8.4Kg of purified diisopropyl adipate into the reactor, add 0.83Kg of PPDI, heat to 65°C, wait until PPDI is completely dissolved, and stir evenly. Keep this temperature, and then add the d...

Embodiment 2

[0051] The polyol PTMEG1000 was vacuum dehydrated at 130° C. for 3 hours to remove the moisture in the polyol and set aside. Under a nitrogen atmosphere, at a temperature of 65°C, add 1.16Kg of PPDI to 13.9Kg of diisopropyl adipate solvent and stir evenly to fully dissolve the PPDI, then add 0.36Kg of the above-mentioned polyol into the reactor while stirring, and continue Stir for 3 hours. The molar ratio of PPDI to polyol is 20:1, and the mass ratio of solvent to solute is 9:1. Then add the above mixture into a thin film evaporator, set the internal temperature of the film to 120°C, set the vacuum degree to 40-60Pa, set the condensation temperature to 20-35°C, collect the light component distillate, and measure the NCO value to be 3.85 %.

[0052] Under the protection of nitrogen, pour 8.4Kg of purified diisopropyl adipate into the reactor, add 1.07Kg of PPDI, heat to 65°C, wait until PPDI is completely dissolved, and stir evenly. Keep this temperature, and then add the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com