Permeable closed amphoteric emulsion for primer and preparation method thereof

A technology of sealing and primer, applied in the direction of primer, coating, etc., can solve the problems of vigorous promotion and application of unsealable primer, wall foundation reinforcement performance that cannot be loosened, and insufficient maintenance time of cement substrate, etc., to achieve excellent Penetration reinforcement performance, improvement of permeability performance, and strong anti-salinity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

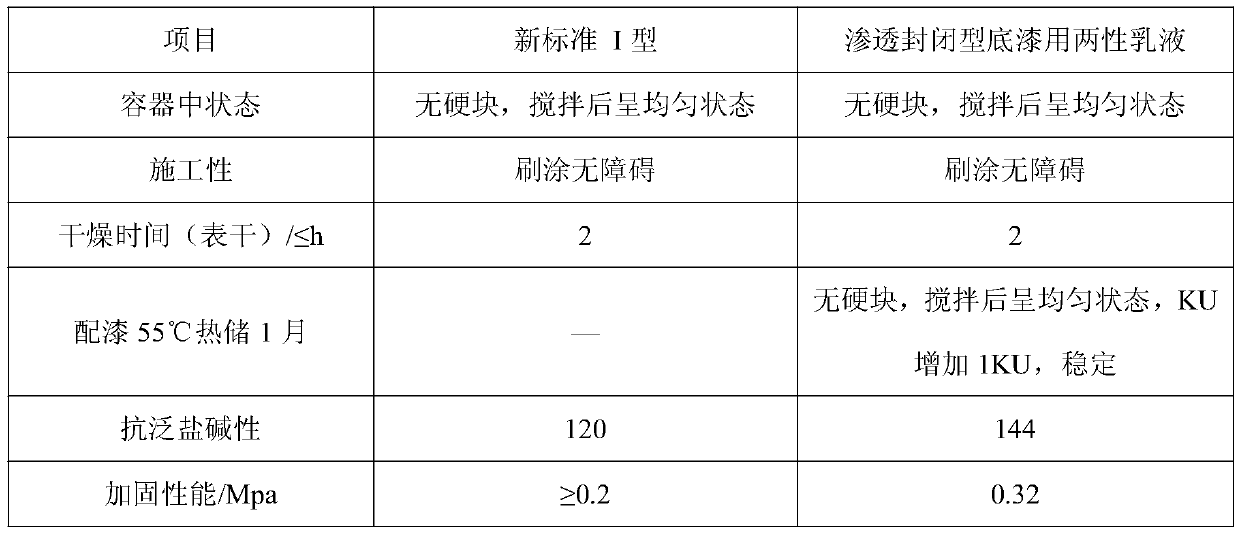

Examples

preparation example Construction

[0033] In addition, the present invention also provides a method for preparing the amphoteric emulsion for the penetration-blocking primer, comprising the following steps:

[0034] 1) Preparation of pre-emulsion: Add 1.5-3.75 parts of emulsifier and 40-85 parts of deionized water into the emulsification tank under normal temperature and pressure. After fully stirring and dissolving, slowly add the formula amount of benzene while stirring Ethylene, n-butyl acrylate in formulated amount, isooctyl acrylate in formulated amount, glycidyl methacrylate in formulated amount, cationic monomer in formulated amount, anionic monomer in formulated amount, hydrophilic monomer in formulated amount, 0.4 - 2 parts of cross-linking monomer and 0.3-1.2 parts of initiator, fully stirred for 30-40 minutes to obtain a pre-emulsion;

[0035] 2) Preparation of seed emulsion: under normal temperature and pressure, add the remaining amount of emulsifier and the remaining amount of deionized water into...

Embodiment 1

[0039] An amphoteric emulsion for a penetrating and sealing primer, made of the following raw materials in parts by mass: 60 parts of deionized water, 50 parts of styrene, 5 parts of n-butyl acrylate, 5 parts of isooctyl acrylate, and 2 parts of emulsifier Parts, 2 parts of glycidyl methacrylate, 3 parts of lauryl methacrylate, 3 parts of methyl erucate, 2 parts of cationic monomer, 2 parts of anionic monomer, 1 part of cross-linking monomer, hydrophilic 3 parts of monomer, 1 part of initiator.

[0040] The emulsifier is mixed with N-(ethyl 1,2-dicarboxylate)-N-octadecylamine sulfosuccinate sodium salt and polyethylene glycol methacrylate at a mass ratio of 2:1. The cross-linking monomer adopts trimethylolpropane trimethacrylate.

[0041] The cationic monomer is mixed with acryloyloxyethyl trimethyl ammonium chloride and dimethyl diallyl ammonium chloride at a mass ratio of 1:1. The anionic monomer adopts acrylic acid.

[0042] The hydrophilic monomer is mixed with acrylami...

Embodiment 2

[0052] An amphoteric emulsion for a penetrating and sealing primer, made of the following raw materials in parts by mass: 70 parts of deionized water, 60 parts of styrene, 10 parts of n-butyl acrylate, 10 parts of isooctyl acrylate, and 3 parts of emulsifier 5 parts, glycidyl methacrylate 5 parts, lauryl methacrylate 5 parts, methyl erucate 5 parts, cationic monomer 5 parts, anionic monomer 3 parts, crosslinking monomer 2 parts, hydrophilic 5 parts of monomer, 1.5 parts of initiator.

[0053] The emulsifier is mixed with cetyltrimethylammonium bromide and allyloxypolyoxyethylene ether in a mass ratio of 5:1.

[0054] The crosslinking monomer is mixed with vinyl tris(methoxyethoxy)silane and pentaerythritol triallyl ether in a mass ratio of 1:1.

[0055] The cationic monomer is mixed with acryloyloxyethyltrimethylammonium chloride, dimethyldiallylammonium chloride and dimethylaminoethyl methacrylate in a mass ratio of 1:2:1.

[0056] The anionic monomer is mixed with acrylic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com