Silica gel carrier, silica gel-loaded alkyl aluminometallocene catalyst, long-chain branched polyethylene and preparation method and application of long-chain branched polyethylene

A kind of alkylaluminum metallocene, long-chain branching technology, applied in the long-chain branched polyethylene and its preparation, the field of alkylaluminum metallocene catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The invention provides a preparation method of a silica gel carrier, comprising the steps of:

[0050] The sodium silicate aqueous solution and organosilicone are mixed to obtain a silicon source solution; the organosilanol has a structure shown in any one of formulas I to III:

[0051] SiR 1 n (OH) 4-n Formula I, SiR 1 p R 2 q (OH) 4-p-q Formula II or SiR 1 R 2 R 3 (OH) Formula III, wherein n is 1, 2 or 3, p and q are independently 1 or 2, and 4-p-q>0, R 1 , R 2 and R 3 are independently alkyl, aryl, alkoxy, phenol or amine;

[0052] Adding the silicon source solution and the acid solution dropwise into water at the same time to obtain a hydrated silica gel; then adjusting the pH value of the hydrated silica gel to 9-10, and then performing thermal aging to obtain a silica gel precursor;

[0053] The silica gel precursor is sequentially acidified, washed and dried to obtain a silica gel carrier; the acidification solution for acidification is a strong oxi...

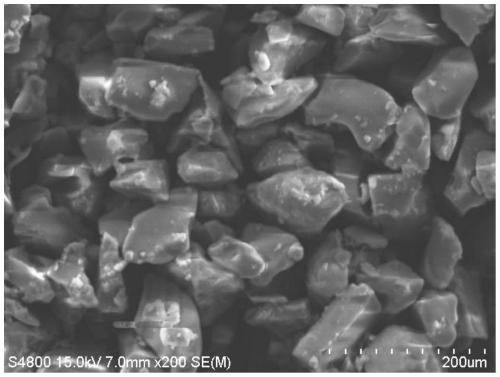

Embodiment 1

[0114] Concentration is the sodium silicate aqueous solution of 40wt% and [(Me 3 Si)PhN]Si(OH) 3 Mix to obtain the silicon source solution, wherein in the silicon source solution [(Me 3 Si)PhN]Si(OH) 3 The concentration is 0.1wt%;

[0115] 10L of the silicon source solution and 1.2L of aqueous hydrochloric acid solution with a concentration of 16wt% were added dropwise to 5L of water at 55°C at a rate of 15 mL / min and 1.8mL / min respectively; The pH value of the glue is 9.4±0.1. After continuing to stir at constant temperature for 3.5 hours, let it stand for 96 hours to age, then pour off the solvent in the reaction solution obtained from aging, wash the obtained solid with water, and cut it into a volume of 0.50±0.01cm 3 The small piece, obtains the silica gel precursor;

[0116] Soak the silica gel precursor in aqua regia, soak at 10°C for 72h, then pour off the aqua regia, and wash the obtained solid with pure water with a conductivity of 5 μS / cm to obtain a crude silica...

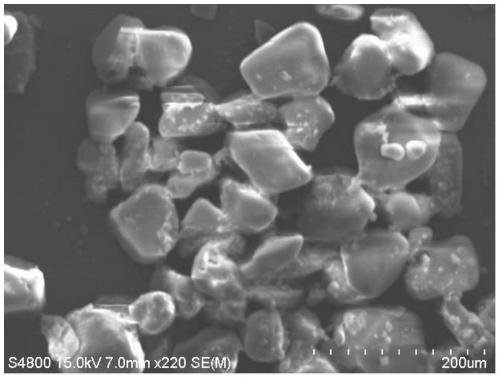

Embodiment 2

[0120] The silica gel carrier was prepared by the method of Example 1, the difference being that the organic silanol [(Me 3 Si)PhN]Si(OH) 3 Replace with [(Me 3 Si)PhN]SiMe(OH) 2 , and the obtained silica gel support was designated as HPS-2.

[0121] The specific surface area of the silica gel carrier obtained in this embodiment is 285 ± 5m by using the BET test method. 2 / g, the average pore diameter is 24.58±1.0nm, and the pore volume is 1.69±0.05mL / g. The sodium ion content measured by atomic absorption spectrometry was 250±10ppm.

[0122] The silica gel carrier obtained in this example was crushed, graded and screened, and tested by a laser particle size analyzer to obtain a silica gel carrier with an average particle size of 48.72±2.5 μm for use (the microscopic appearance is as follows: figure 2 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com