Preparation process of high-strength concrete

A preparation process and concrete technology, which are applied in the field of high-strength concrete preparation technology, can solve the problems of reducing concrete strength, accelerating concrete corrosion rate, unsatisfactory overall strength and stability of concrete structure, etc., so as to save usage and improve strength , Improve the effect of various comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

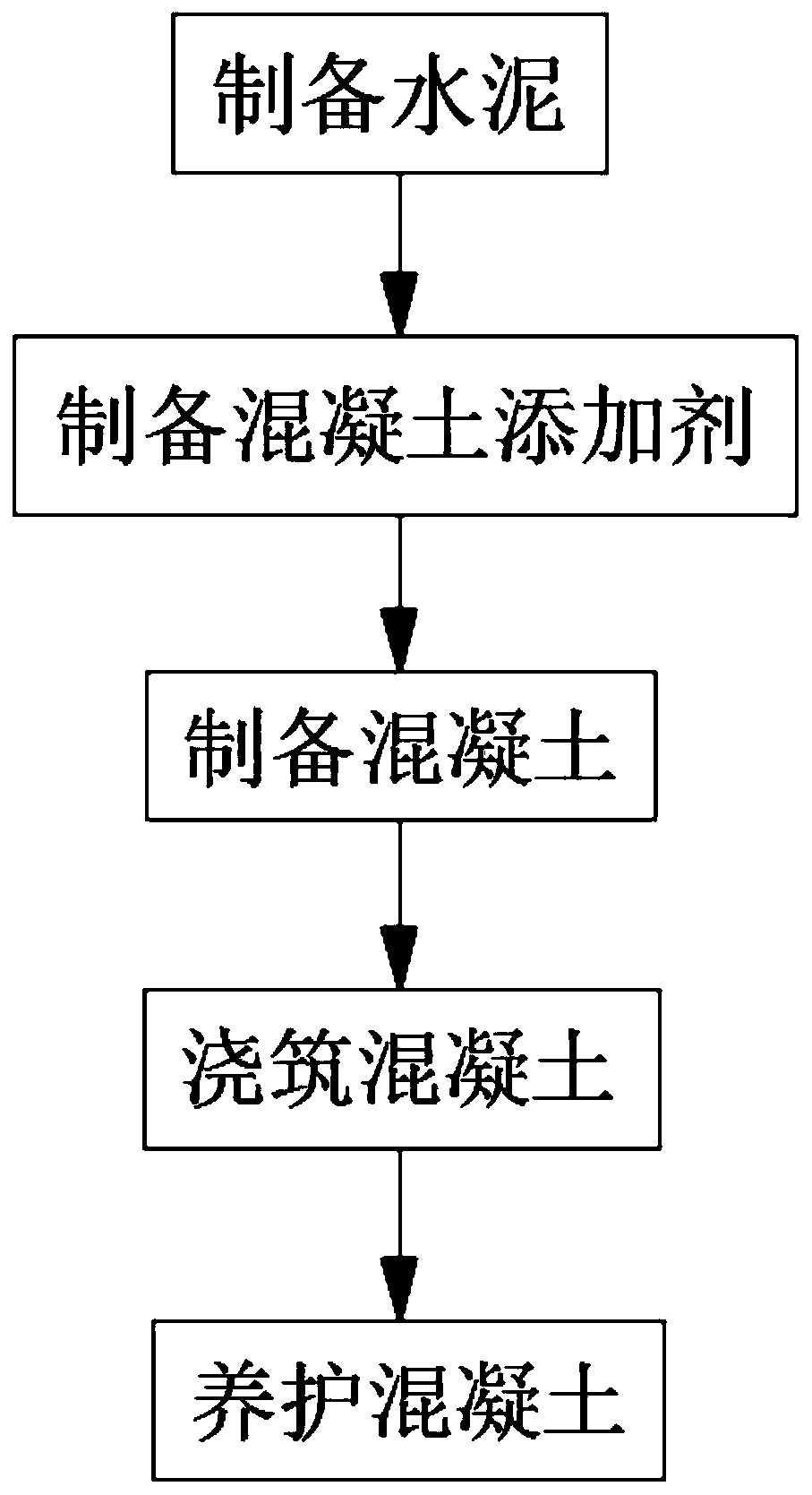

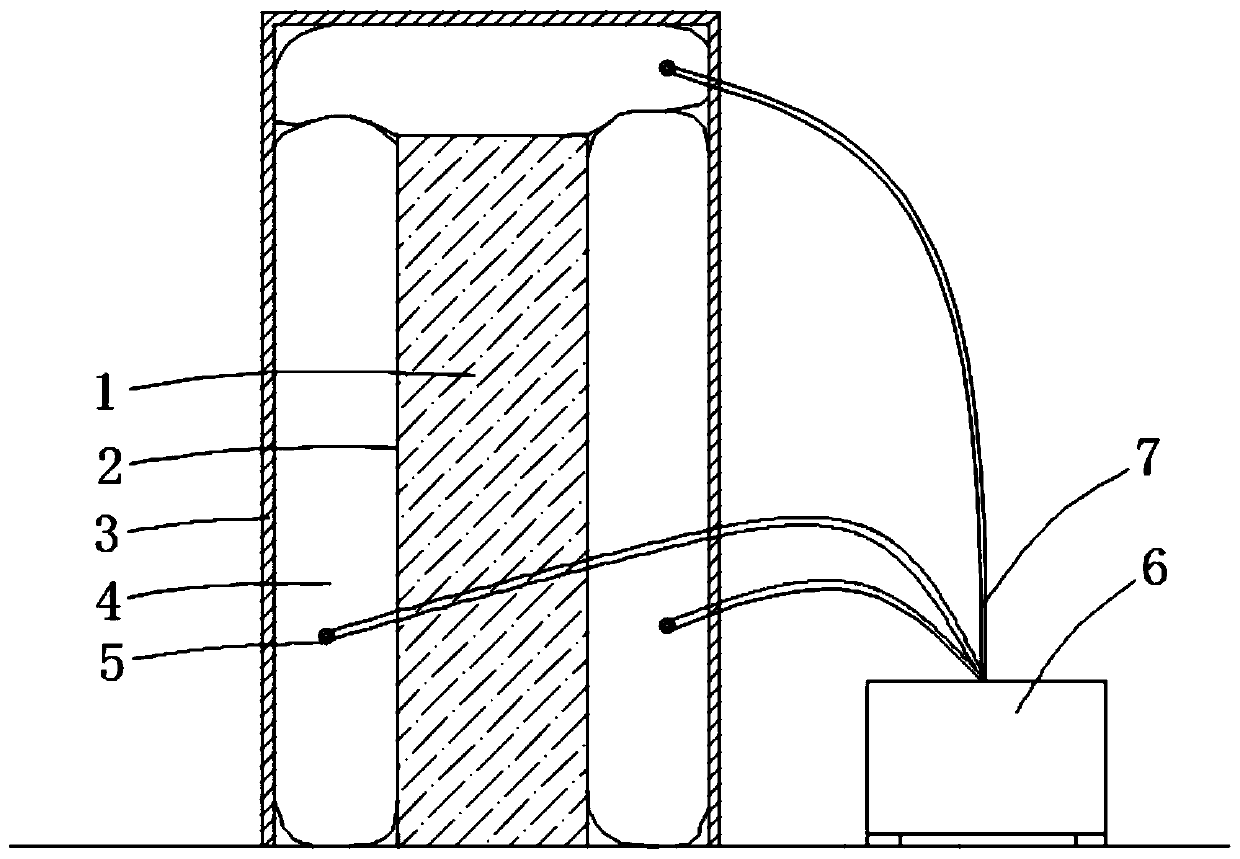

[0037] refer to figure 1 , figure 2 , is a kind of preparation technology of high-strength concrete disclosed by the present invention, comprising the following construction steps:

[0038] S1, preparing cement: Put cement clinker, raw gypsum, fly ash, coal gangue, and calcium stearate into a heating and stirring tank in sequence according to the weight ratio of 11:9:1.2:0.3:0.15, and heat to 100 ~120°C and keep warm for 0.5~1h, then put the mixture into a fine grinder for refining treatment, and then get cement for use;

[0039] S2, preparation of concrete additives: sodium p-hydroxybenzenesulfonate, triphenyl phosphite, modified chitosan, barium stearate, and dibutyltin laurate in sequence in a weight ratio of 14:12:6:2.5:0.02, Put them together in the mixing tank for full mixing, then you can get the concrete additive for use;

[0040] S3, preparation of concrete: Put the cement and concrete additives prepared in the above steps together with water, fine aggregate, anti...

Embodiment 2

[0044] refer to figure 1 , figure 2 , is a kind of preparation technology of high-strength concrete disclosed by the present invention, comprising the following construction steps:

[0045] S1, preparation of cement: Put cement clinker, raw gypsum, fly ash, coal gangue, and calcium stearate into the heating and stirring tank in sequence according to the weight ratio of 10:8:1:0.2:0.1, and heat to 100 ~120°C and keep warm for 0.5~1h, then put the mixture into a fine grinder for refining treatment, and then get cement for use;

[0046] S2, preparation of concrete additives: sodium p-hydroxybenzenesulfonate, triphenyl phosphite, modified chitosan, barium stearate, and dibutyltin laurate in sequence in a weight ratio of 10:10:5:2:0.01, Put them together in the mixing tank for full mixing, then you can get the concrete additive for use;

[0047] S3, preparing concrete: put the cement and concrete additives prepared in the above steps into the concrete mixer together with water,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com