A kind of preparation method of miniature graphene airgel device

A graphene airgel and device technology, applied in graphene, electrical components, structural parts, etc., can solve the problems of performance degradation, difficulty in miniaturization, integration and large-scale production, and achieve high stability, The effect of excellent flexibility and stability, high precision and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Use 20mg / ml graphene oxide aqueous suspension as ink, print on polyimide substrate by 3D printing method, the droplet diameter is about 20um; after curing, add dropwise an aqueous solution containing hydrazine hydrate with a concentration of 50% 0.1ml, to make the graphene oxide plasticized and foamed, dried after 5 minutes, and obtained micro-graphene airgel units after in-situ reduction of hydroiodic acid.

[0050] A cross-sectional scan of the polyimide substrate, such as Figure 18 As shown, it can be seen from the figure that the graphene airgel is formed on the polyimide substrate, and the graphene sheets overlap each other to form a pore structure, and its porosity is almost the same as that of the conventional foamed graphene airgel. It can be predicted that this graphene aerogel has the mechanical properties, electrical properties, electromechanical properties, etc. of the macroscopic aerogels prepared by conventional methods.

[0051] In addition, the graphen...

Embodiment 2

[0053] Add an equal mass of sodium bicarbonate to the DMF suspension of 10 mg / ml graphene oxide and mix evenly (the mass ratio of graphene oxide solution to sodium bicarbonate is 1:1) to obtain graphene oxide ink for 3D printing.

[0054] Use 3D printing to print on a transparent PET substrate, and the droplet diameter is about 20um; after drying and curing, place it in water, heat it at 40 degrees Celsius to generate air bubbles, dry it after 1 minute, and reduce it in situ with hydroiodic acid to obtain micro Graphene airgel unit.

[0055] Cross-sectional scanning of the PET substrate, such as Figure 19 As shown, it can be seen from the figure that the graphene airgel is formed on the PET substrate, and the graphene sheets overlap each other to form a pore structure, and its porosity is almost the same as that of the conventional foamed graphene airgel. It can be predicted that this graphene aerogel has the mechanical properties, electrical properties, electromechanical pr...

Embodiment 3

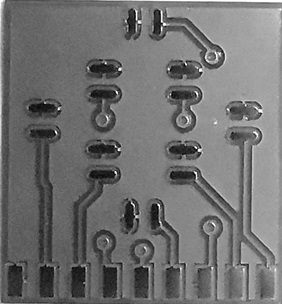

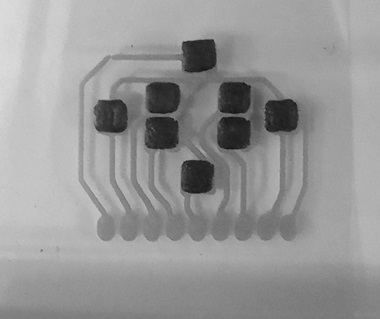

[0058] On the polyimide substrate (0.8×1.0mm) by screen printing 2 ) prints as figure 1 The circuit diagram of the sensor with 8 pairs of electrodes is shown, where the size of a single electrode is 50×100um 2 , each pair of electrodes constitutes a test unit. In addition, 8 lead-out electrodes and a total electrode are set at the bottom; 3D printing of graphene oxide ink is then carried out on the test unit in the circuit diagram, wherein the graphene oxide solution is a 20mg / ml water suspension, after drying and curing, drop Add 0.1ml of an aqueous solution of hydrazine hydrate with a concentration of 50% (also dropwise by 3D printing, the same below) to foam graphene oxide in situ, dry it after 5 minutes, and obtain hydriodic acid in situ reduction A stable array sensor in which individual micrographene airgel units are 150 × 150 um in size 2 Within, and covered on the corresponding pair of electrodes.

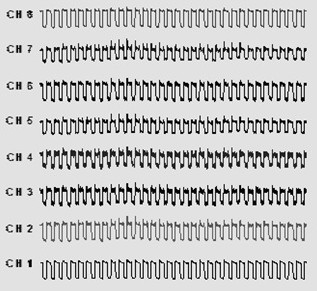

[0059] Lead the circuit of the 8-electrode sensor to the data acqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com