High-strength recyclable honeycomb finished cigarette carton

A high-strength, honeycomb technology, applied in the field of cartons, can solve the problems of strength damage, pressure resistance, damage, etc., and achieve the effect of improving compressive strength, reducing deformation damage, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

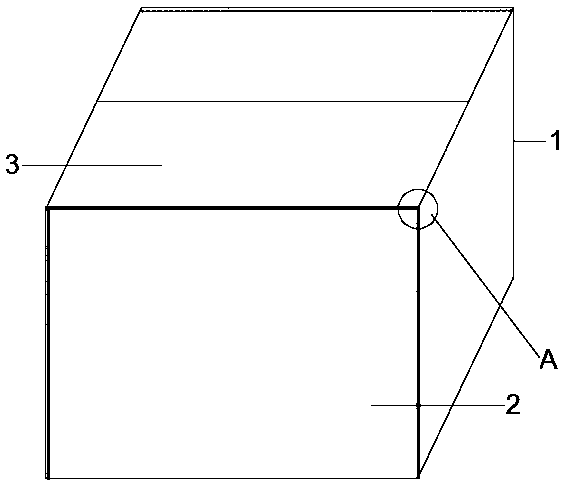

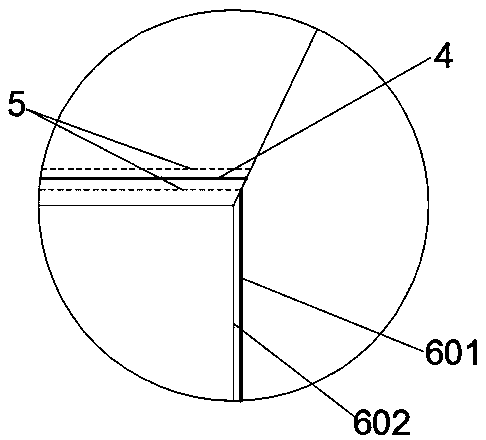

[0035] refer to Figure 1~Figure 8 : A high-strength recyclable honeycomb finished smoke box, including a box body 1, the box body 1 includes a side plate 2 and a cover plate 3 connected to the upper and lower ends of the side plate 2, the side plate 2 and the cover plate 3 form a closed Space, the side panel 2 is formed by bending and splicing a piece of honeycomb paperboard 12 three times. The folded part of the cover panel 3 and the side panel 2 is provided with two indentations distributed on the inside of the box body 1 and the box body 1 One indentation indentation on the outer side; one indentation indentation 4 on the inner side of the box body 1 and two indentation indentations 4 on the outer side of the box body 1 are provided at the bending place between the adjacent side plates 2 .

[0036] In this embodiment, one side of the side plate 2 is provided with a connection ear 11, and the other side is reserved with a connection area 10 connected to the connection ear 1...

Embodiment 2

[0050] refer to Figure 9 and Figure 10 , compared with embodiment 1, a kind of high-strength recyclable honeycomb finished smoke box of the present embodiment has the following differences:

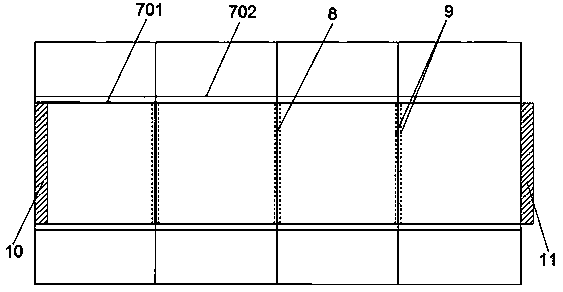

[0051] In this embodiment, the thickness of the honeycomb paperboard 12 for the finished cigarette box is selected as 12 mm. The number of inversion indentations at the turnover of the cover plate 3 and the side plate 2 is 3, including the first inversion indentation 701, the second inversion indentation 702 and the third inversion indentation 703, the first inversion indentation The inversion indentation 701 is located between the second inversion indentation 702 and the third inversion indentation 703, and the depth of the first inversion indentation 701 is 2 / 3 of the thickness of the honeycomb paperboard 12 for the honeycomb finished cigarette box, that is, 8mm , the depth of the second inversion indentation 702 is 1 / 2 of the thickness of the honeycomb paperboard 12 for the honeyco...

Embodiment 3

[0063] refer to Figure 11 and Figure 12 , compared with embodiment 1, a kind of high-strength recyclable honeycomb finished smoke box of the present embodiment has the following differences:

[0064] In this embodiment, the finished honeycomb smoke box is formed by splicing two honeycomb paperboards 12 , which are defined as a first honeycomb paperboard 13 and a second honeycomb paperboard 14 .

[0065] In this embodiment, one side of the two honeycomb paperboards 12 is provided with a connecting ear 11, and the other side is provided with a connecting area 10, the two honeycomb paperboards 12 are folded once, and the upper and lower ends of the honeycomb paperboards 12 are cut Cover plates 3 are formed, and the parts between the cover plates 3 are side plates 2 . The connection ears 11 of the first honeycomb paperboard 13 and the connection area 10 of the second honeycomb paperboard 14 are glued or nailed, and the connection ears 11 of the second honeycomb paperboard 14 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com