Tea packaging tin manufacturing method

A production method and technology of packaging cans, which are applied in the field of tea packaging, can solve the problems of iron roll size change, excessive bending, loose iron roll, etc., so as to reduce the probability of upturning or offset, reduce offset and The effect of re-flattening and improving the relative stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

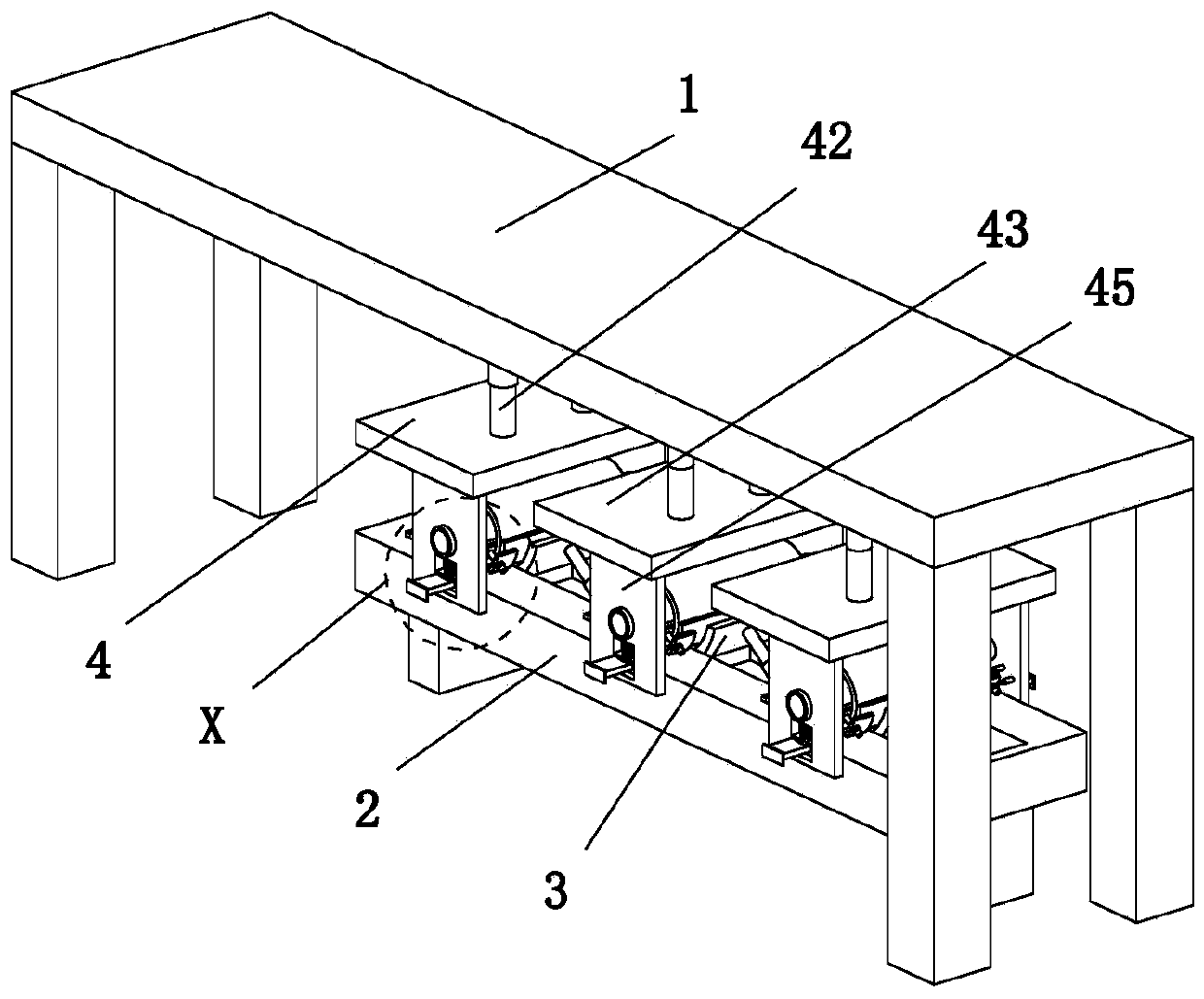

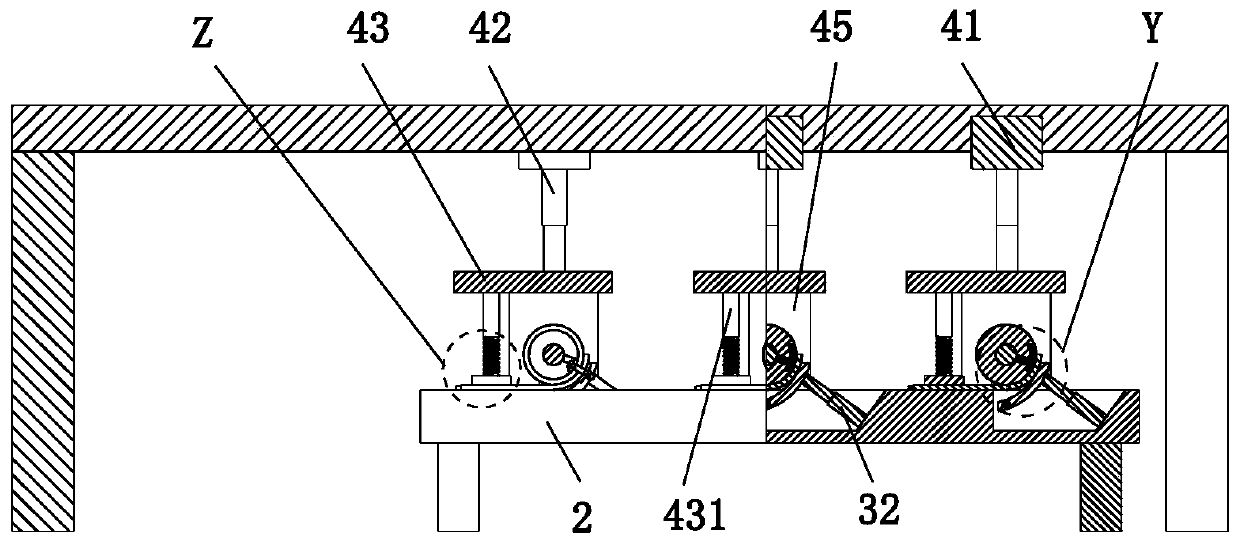

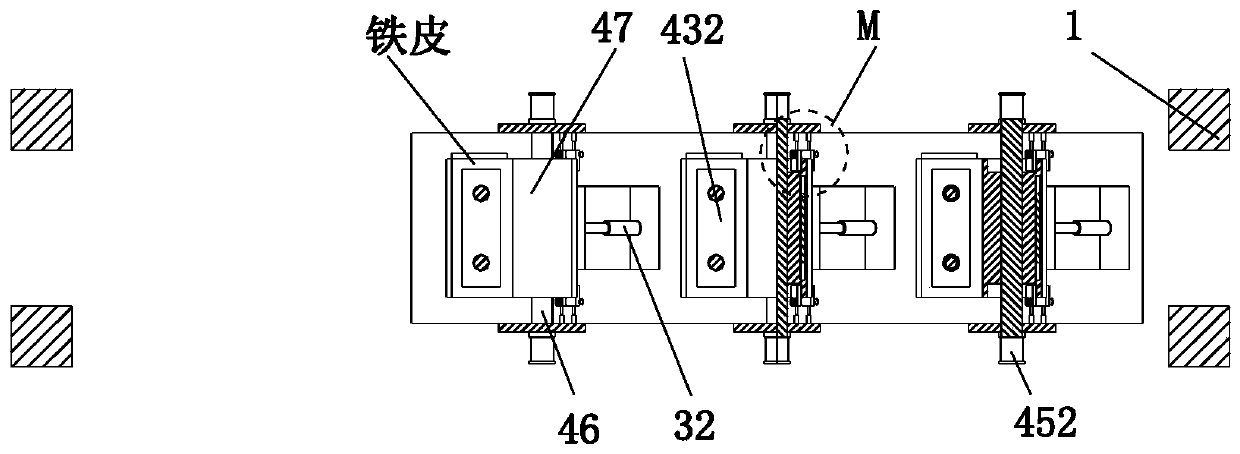

[0034] Such as Figure 1 to Figure 7 As shown, a method for making a tea packaging can, which uses a tea packaging can manufacturing device, which includes a gantry 1, a workbench 2, an auxiliary device 3 and an edge device 4, When adopting above-mentioned a kind of tea packaging can production device to carry out tea packaging can production, concrete production method is as follows:

[0035] S1. Pre-bending: push the arc turning plate 33 obliquely upward to the left through the No. 1 electric push rod 32, and the arc turning plate 33 pushes the iron sheet to move synchronously. Block 49 absorbs the iron sheet on the mandrel 47;

[0036] S2, side-lapping: through the electric slider 41, the vertical plate 45 drives the rotating shaft 46 to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com