Film capacitor element, film capacitor, and method of producing the film capacitor element

A film capacitor and thin film technology, applied in the direction of film/thick film capacitors, capacitors, electrical components, etc., can solve the problems of affecting the dielectric covering film layer and increasing the possibility of peeling off the dielectric covering film layer, so as to prevent adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further clarify the present invention, the embodiments of the present invention are described in detail by referring to the accompanying drawings.

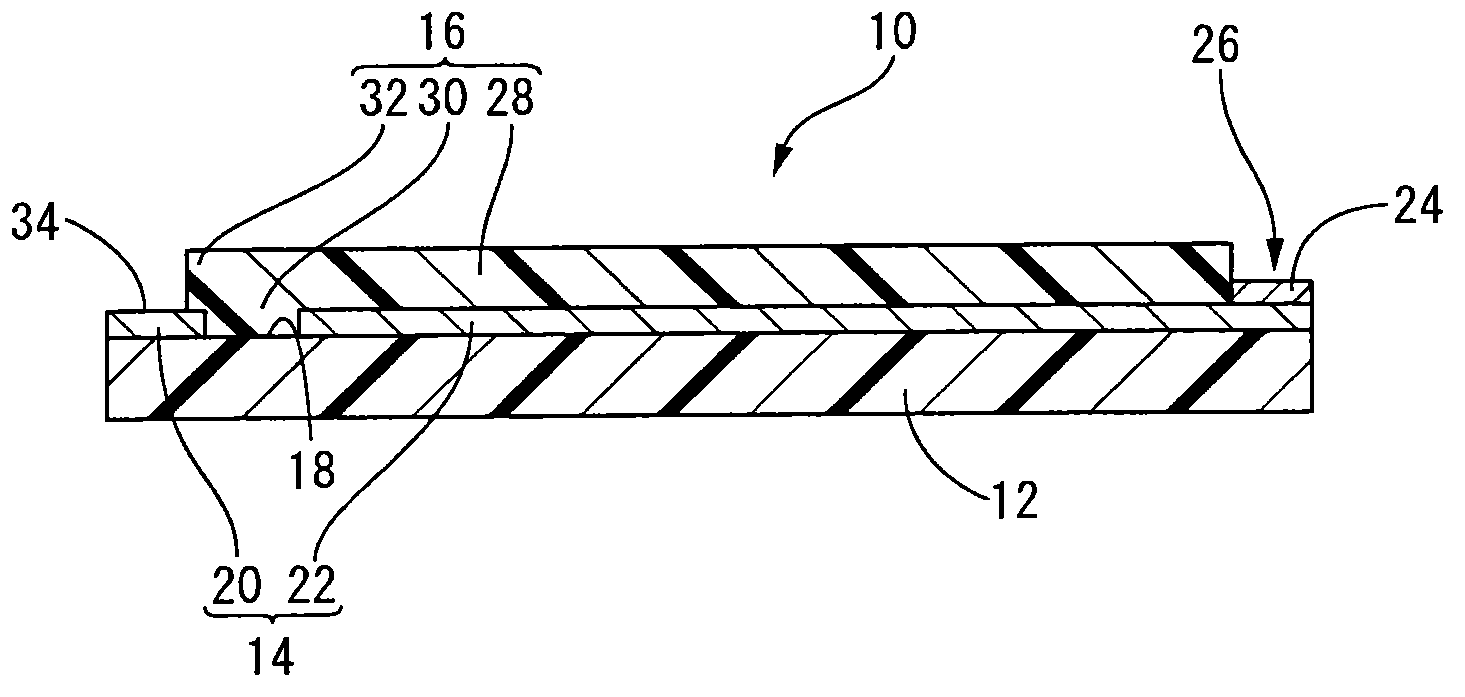

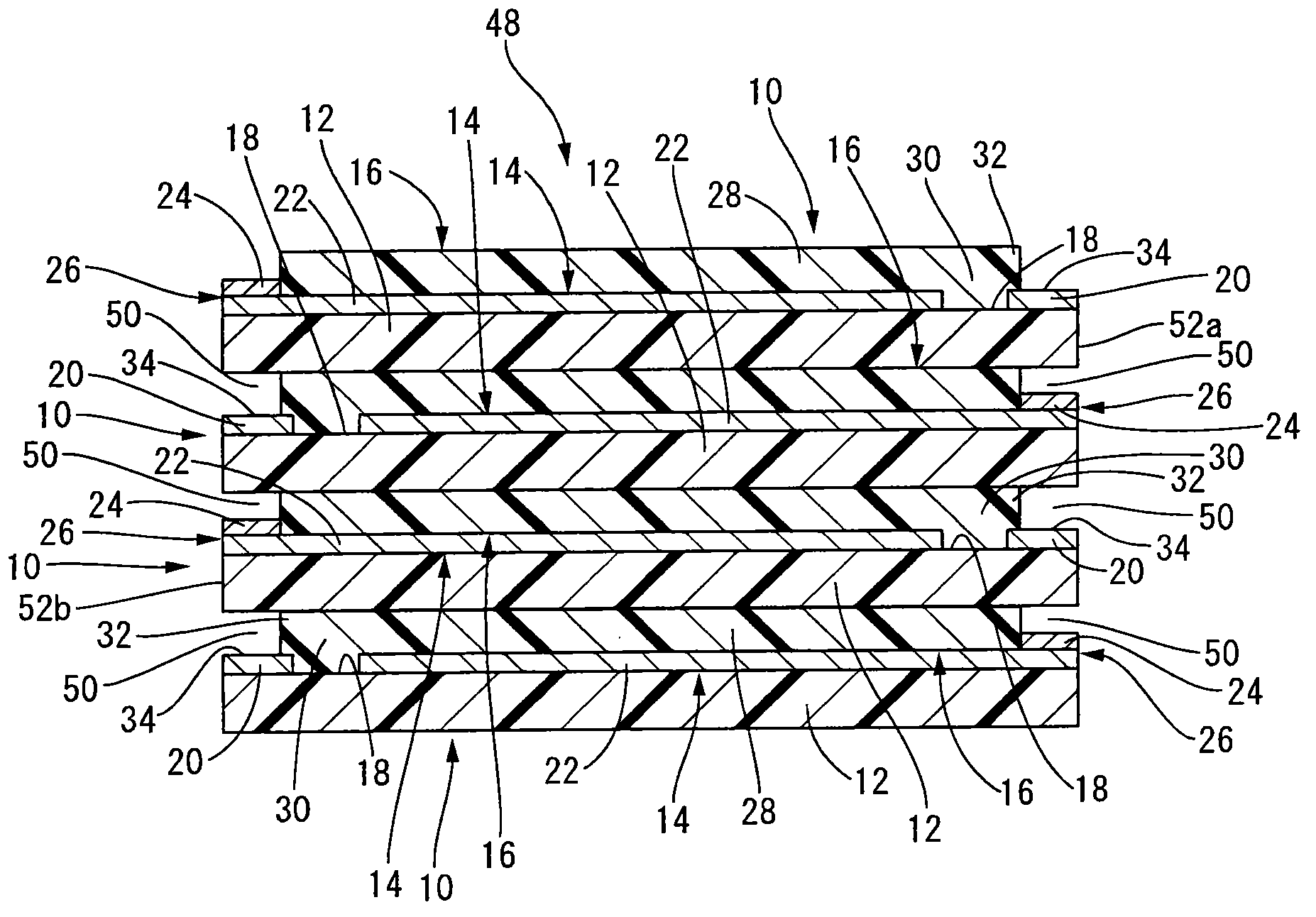

[0048] figure 1 A film capacitor element 10 constructed in accordance with one embodiment of the present invention is shown in cross section. Such as figure 1 As shown, the film capacitor element 10 of the present embodiment has a resin film 12 as a base dielectric film layer, a vapor-deposited metal film layer as a vapor-deposited metal film layer formed on one of the opposite main surfaces of the resin film 12 in the thickness direction. film 14 and a vapor-deposited polymer film 16 as a dielectric capping film layer formed on the surface of the vapor-deposited metal film 14 remote from the resin film 12 . That is, the film capacitor element 10 of the present embodiment has a base dielectric film layer (resin film 12), a vapor-deposited metal film layer (vapor-deposited metal film 14), and a dielectric cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com