Anti-virus breathable cloth, production method for manufacturing anti-virus breathable cloth and application of anti-virus breathable cloth

A production method and technology of breathable cloth are applied in the production, design and application field of breathable cloth for raw materials of medical protective equipment, which can solve the problems of waste of raw material resources and secondary pollution of masks, and achieve the effect of saving raw material resources of masks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

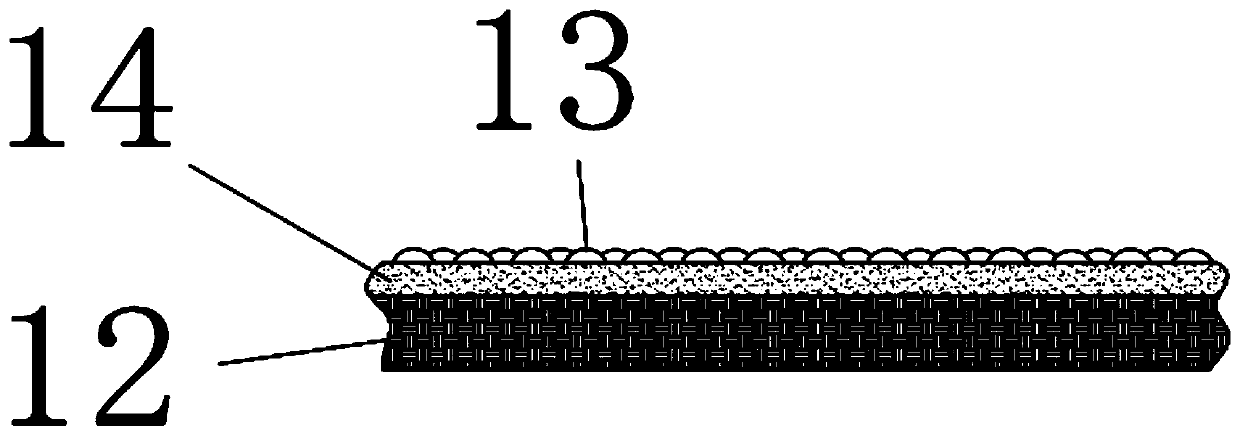

[0038] The content (mass percentage) of chloroquine phosphate in the water-soluble anti-virus powder glue liquid of chloroquine phosphate anti-toxin powder is 5%-98%.

Embodiment 2

[0040] The content (mass percentage) of Radixivir in the water-soluble antitoxin powder and glue solution of Radixivir antitoxin powder is 5%-98%.

Embodiment 3

[0042] The content of fapilavir (mass percentage) in the water-soluble antivirus powder and glue liquid of favipiravir antitoxic powder is 5%-98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com