Stent and medical device comprising same

A technology of medical equipment and elastic yarn, which is applied in the field of biodegradable stents, can solve the problems of large resistance and difficulty in expanding the end of the stent, and achieve the effect of expansion, high recovery from deformation, and reliable expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

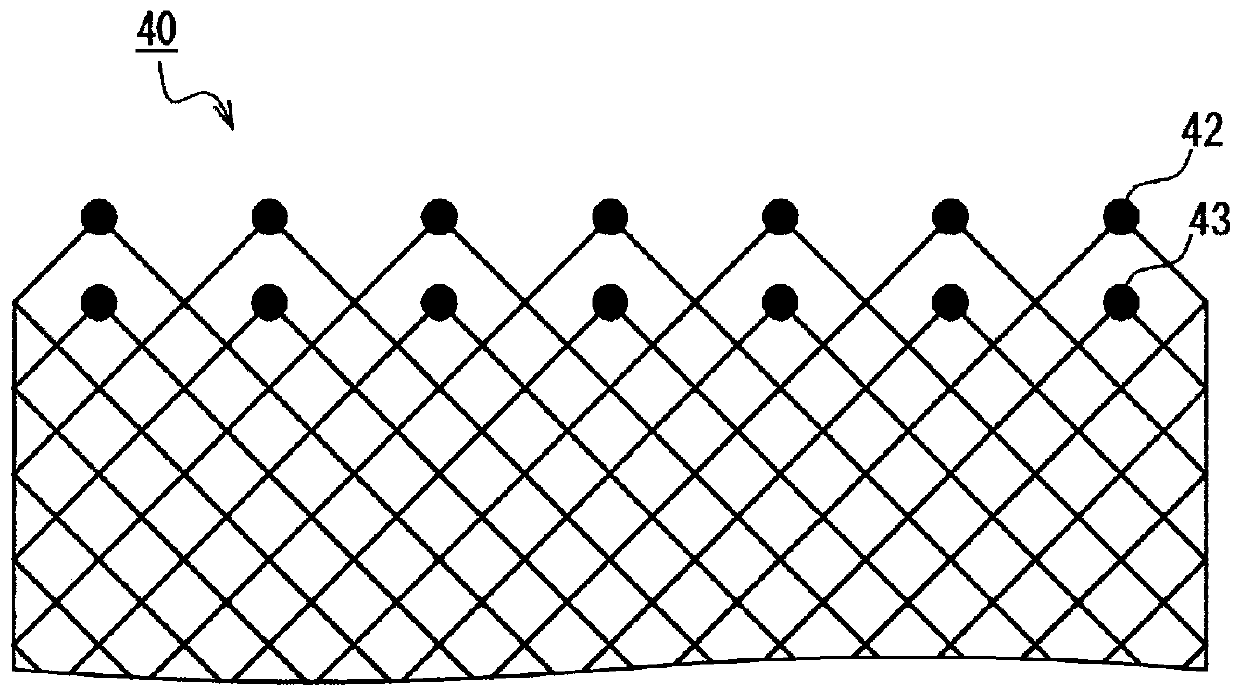

[0088] As a biodegradable polymer, polyglycolic acid with an intrinsic viscosity of 1.51dL / g (0.1g / dL HFIP, 25°C) is used, melt-spun at a temperature of 190-245°C, and stretched to a draw ratio 4 to 5 times, heat setting was carried out at a temperature of 100 to 120°C. The obtained monofilament had a diameter of 0.265 mm. Using this monofilament, use Figure 6~7 The braiding manufacturing device shown (it is 32 strands of braiding manufacturing device), made Figure 4 bracket shown. The yarns at both ends of the stent were welded by ultrasonic welding, solidified, and bonded so that the bonding points were arranged in two rows in the longitudinal direction.

[0089] The stent has an outer diameter of 20 mm in an expanded state, and three bundles of elastic polyurethane yarns: "Pellethane" (diameter: 70 μm) manufactured by Lubrizol in the United States (diameter: 70 μm) are inserted at equal intervals on the circumference. 4 places. In addition, the braiding angle θ of ea...

Embodiment 2

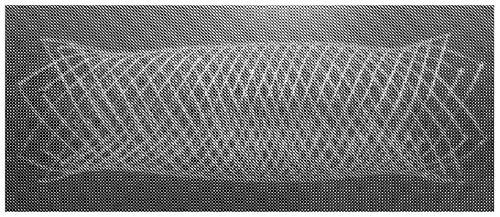

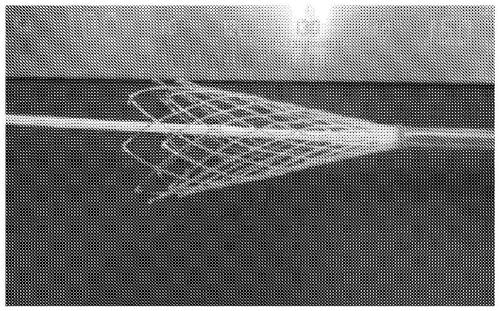

[0094] Using 32 monofilaments (0.23 mm in diameter) made of polyglycolic acid, a braided stent (22 mm in diameter and 80 mm in length) was produced with a braiding manufacturing device. On the braided bracket, polyurethane elastic yarn (USA Lubrizol company, trade name "Pellethane" (200 μm in diameter)) such as Figure 9As shown, it is arranged on the outside of the bracket and fixed at both ends of the bracket. Wherein, the two ends of the bracket are arranged in two rows in the length direction. Four polyurethane elastic yarns were arranged at equal intervals on the circumference of the holder. When the braided yarn holder is mounted on Figure 8 After the delivery system with an inner diameter of 3mm as shown, the stent self-expands when pushed out of the delivery system, the central part of the stent expands to the original diameter of 22mm, and the two ends expand to 22-27mm larger than the original diameter. exist Figure 13 In A, a side photo of the stent before the...

Embodiment 3

[0096] In addition to making polyurethane elastic yarns such as Figure 10 A braid holder was fabricated in the same manner as in Example 2, except that the monofilament constituting the braid was intersected at the center of the holder as shown. After the braided yarn stent is mounted on a delivery system with an inner diameter of 3 mm, when pushed out from the delivery system, the stent self-expands, the central part of the stent expands to the original diameter of 22 mm, and the two ends expand to 22 mm larger than the original diameter. -27mm. exist Figure 14 In A, a side photo of the stent before the delivery system is shown is shown, in Figure 14 In B, a profile photo just after release from the delivery system is shown, at Figure 14 In C, a profile photograph 3 minutes after release from the delivery system is shown. It was confirmed that the stent of this example can self-expand uniformly in a short time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com