A multi-motion mode high-voltage transmission line inspection robot

A high-voltage transmission line, multi-motion mode technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of difficulty in crossing obstacles, weak climbing ability, low inspection efficiency, etc., and achieve fast traveling speed and strong climbing ability. , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below in conjunction with the accompanying drawings:

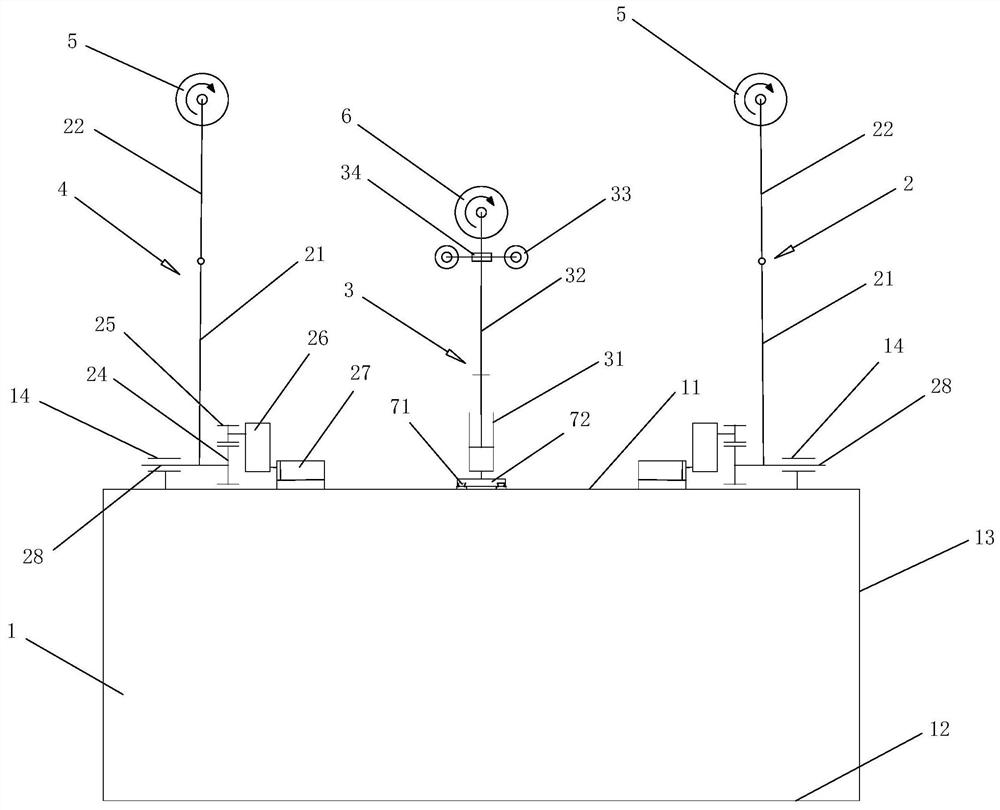

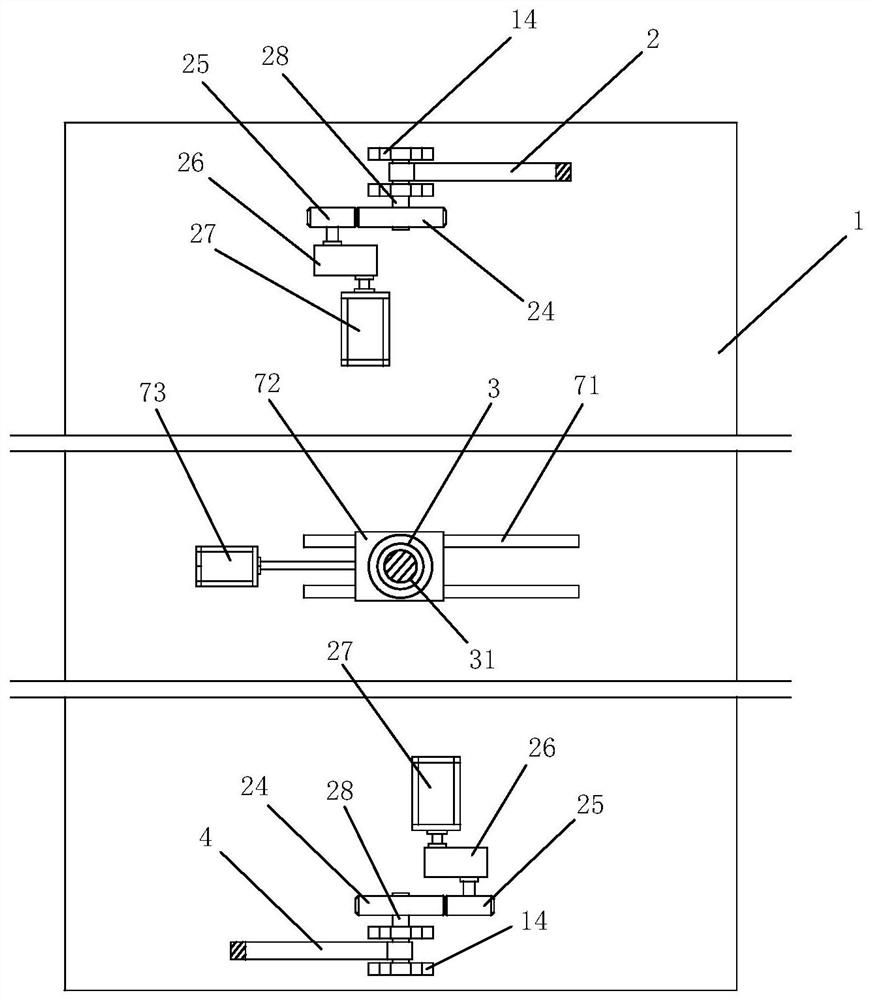

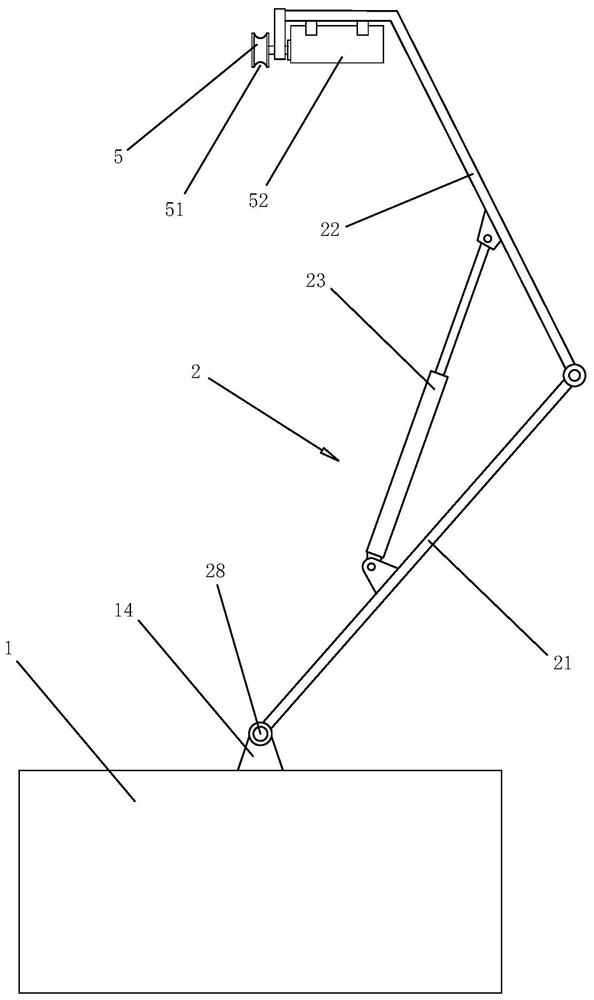

[0044] combine Figure 1 to Figure 13 , a multi-motion mode high-voltage power transmission line inspection robot, including a box body 1, a front robot arm 2, a middle robot arm 3, a rear robot arm 4 and a control system, the box body includes a top plate 11, a bottom plate 12 and four side plates 13. The top plate 11, the bottom plate 12 and the four side plates 13 are welded into a square box-like structure.

[0045] A hinge support 14 is respectively fixed and welded on the front side and the rear side of the top of the box body 1 , and the hinge support 14 is provided with a shaft hole. The front manipulator 2 , the middle manipulator 3 , and the rear manipulator 4 are disposed above the box 1 at intervals from front to back, and the front manipulator 2 , the middle manipulator 3 , and the rear manipulator 4 are all telescopic manipulators. Specifically, the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com