Preparation method and application of layered Steiner network structure fiber membrane

A technology of network structure and fiber membrane, which is applied in the field of explosive detection and analysis, to achieve the effects of strong moisture retention, high sensitivity, and good acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

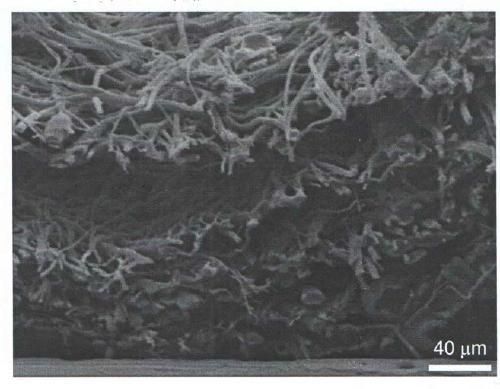

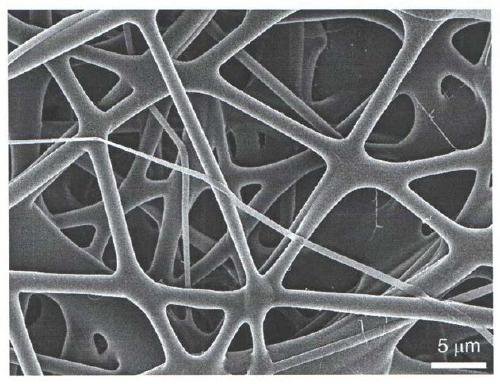

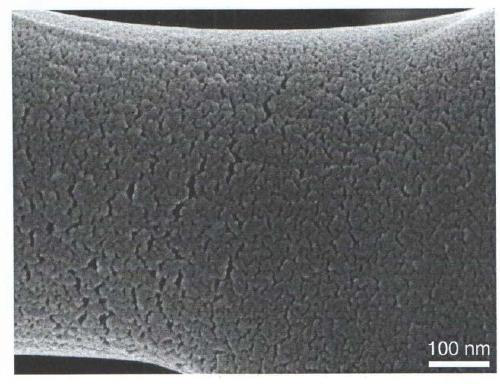

Image

Examples

Embodiment 1

[0025] a. Dissolve 0.2g polymer polyvinyl alcohol in 20g deionized water, heat and stir at 100°C for 1 hour, then cool to room temperature, then add porogen dichloromethane and crosslinking agent glutaraldehyde, and continue stirring for 1 hour Hour, make spinning solution; Wherein, porogen methylene chloride accounts for 1% of the mass fraction of spinning solution, and cross-linking agent glutaraldehyde accounts for 1% of the mass fraction of spinning solution;

[0026] b. Add the spinning solution obtained in step a into the electrospinning syringe, select a 1.64mm needle, the distance between the needle of the syringe and the electrospinning collector is 8cm, the voltage is 11kV, and the flow rate is 0.6ml / h for electrospinning , the spinning time is 60min, and the spinning fiber film is collected with aluminum foil;

[0027] c. After the electrospinning is finished, put the aluminum foil paper and the fiber membrane in a desiccator filled with catalyst hydrochloric acid, ...

Embodiment 2

[0032] a. Dissolve 0.8g polymer chitosan in 20g deionized water, heat and stir at 100°C for 3 hours, then cool to room temperature, then add porogen polyvinyl alcohol and crosslinking agent methylenebisacrylamide, and continue Stir for 1 hour to make a spinning solution; wherein, the porogen polyvinyl alcohol accounts for 50% of the mass fraction of the spinning solution, and the crosslinking agent methylene bisacrylamide accounts for 5% of the spinning solution;

[0033] b. Add the spinning solution obtained in step a into the electrospinning syringe, select a 1.64mm needle, the distance between the needle of the syringe and the electrospinning collector is 5cm, the voltage is 25kV, and the flow rate is 1ml / h for electrospinning. The spinning time is 100min, and the spinning fiber film is collected with aluminum foil;

[0034] c. After the electrospinning is finished, put the aluminum foil paper and the fiber membrane in a drier filled with catalytic sulfuric acid, and cataly...

Embodiment 3

[0039] a. Dissolve 0.5g polymer polyvinylpyrrolidone in 20g deionized water, heat and stir at 100°C for 2 hours, then cool to room temperature, then add porogen dimethyl sulfoxide and crosslinking agent triethanolamine, and continue stirring In 1 hour, a spinning solution was prepared; wherein, the porogen dimethyl sulfoxide accounted for 20% of the mass fraction of the spinning solution, and the crosslinking agent triethanolamine accounted for 2% of the mass fraction of the spinning solution;

[0040] b. Add the spinning solution obtained in step a into the electrospinning syringe, select a 1.64mm needle, the distance between the needle of the syringe and the electrospinning collector is 18cm, the voltage is 8kV, and the flow rate is 0.8ml / h for electrospinning , the spinning time is 180min, and the spinning fiber film is collected with aluminum foil;

[0041] c. After the electrospinning is finished, put the aluminum foil paper and the fiber membrane in a drier filled with c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com