Wiredrawing processing machine for manufacturing woven bag

A wire drawing processing and woven bag technology, which is used in filament generation, textile and papermaking, filament/thread forming, etc., can solve the problems of hindering winding work, inward shrinkage of cutting parts, and pulling, etc., to reduce incompleteness. The effect of reducing the probability of cutting phenomenon, reducing the probability of complete cutting phenomenon, and reducing the probability of multi-directional wire drawing phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

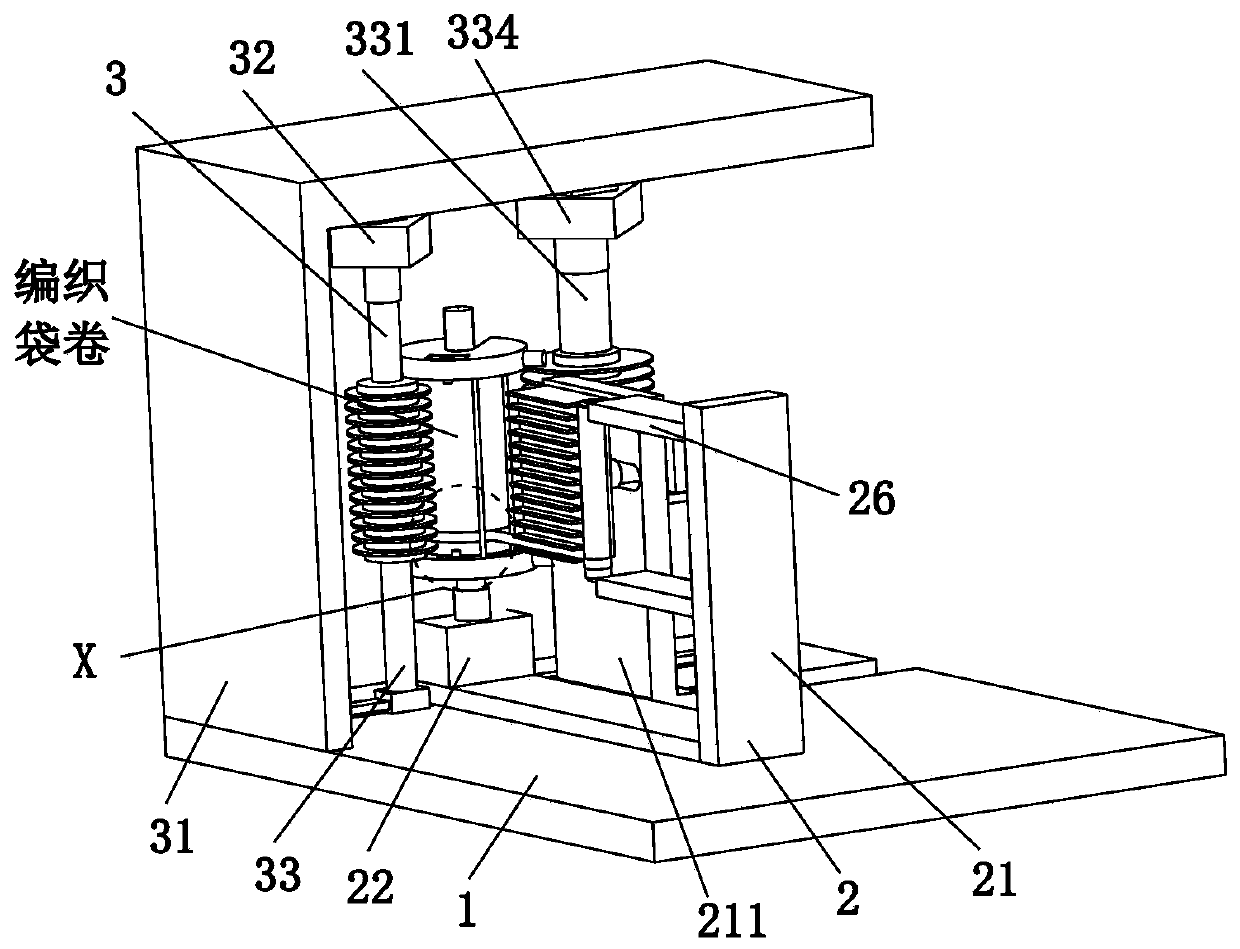

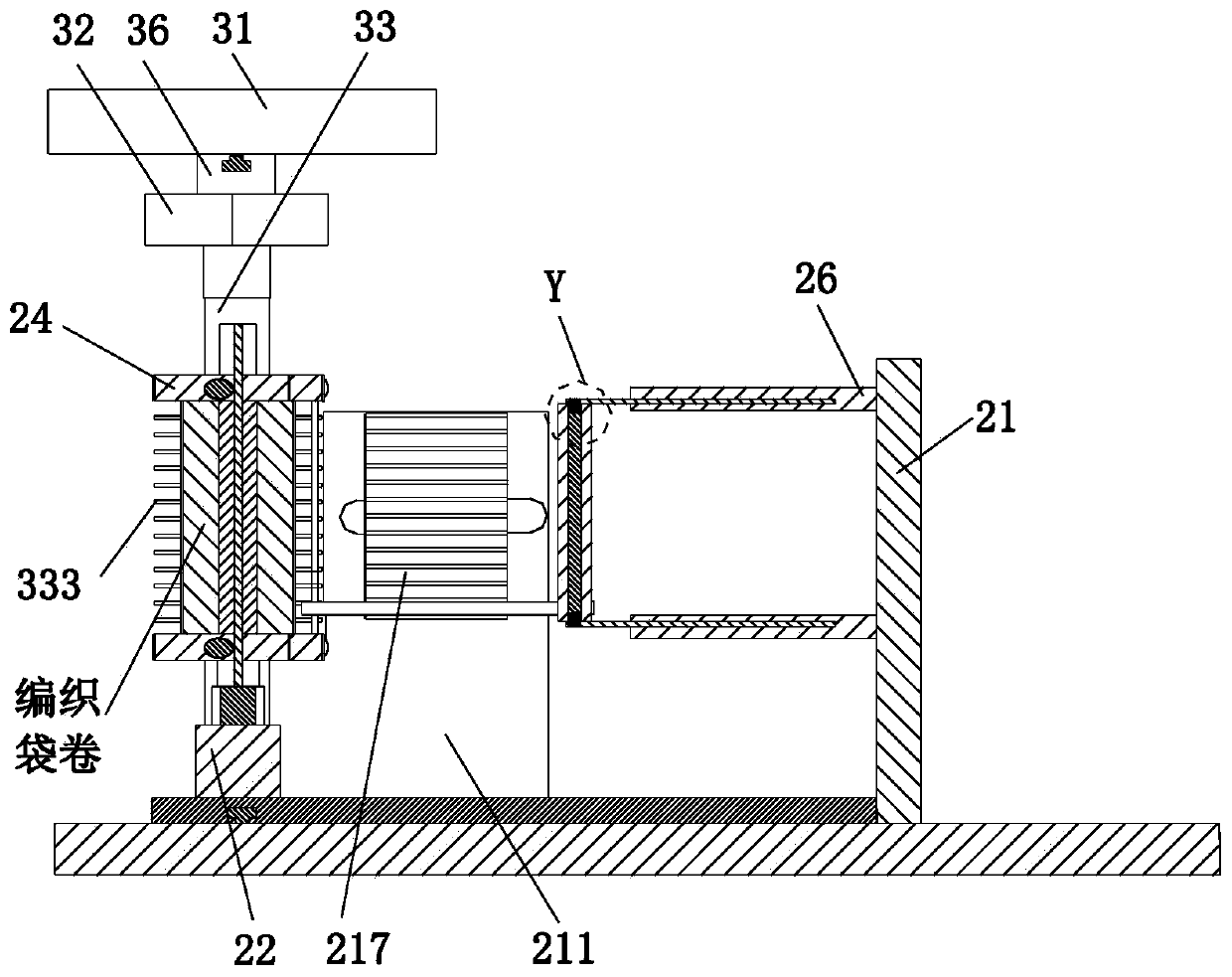

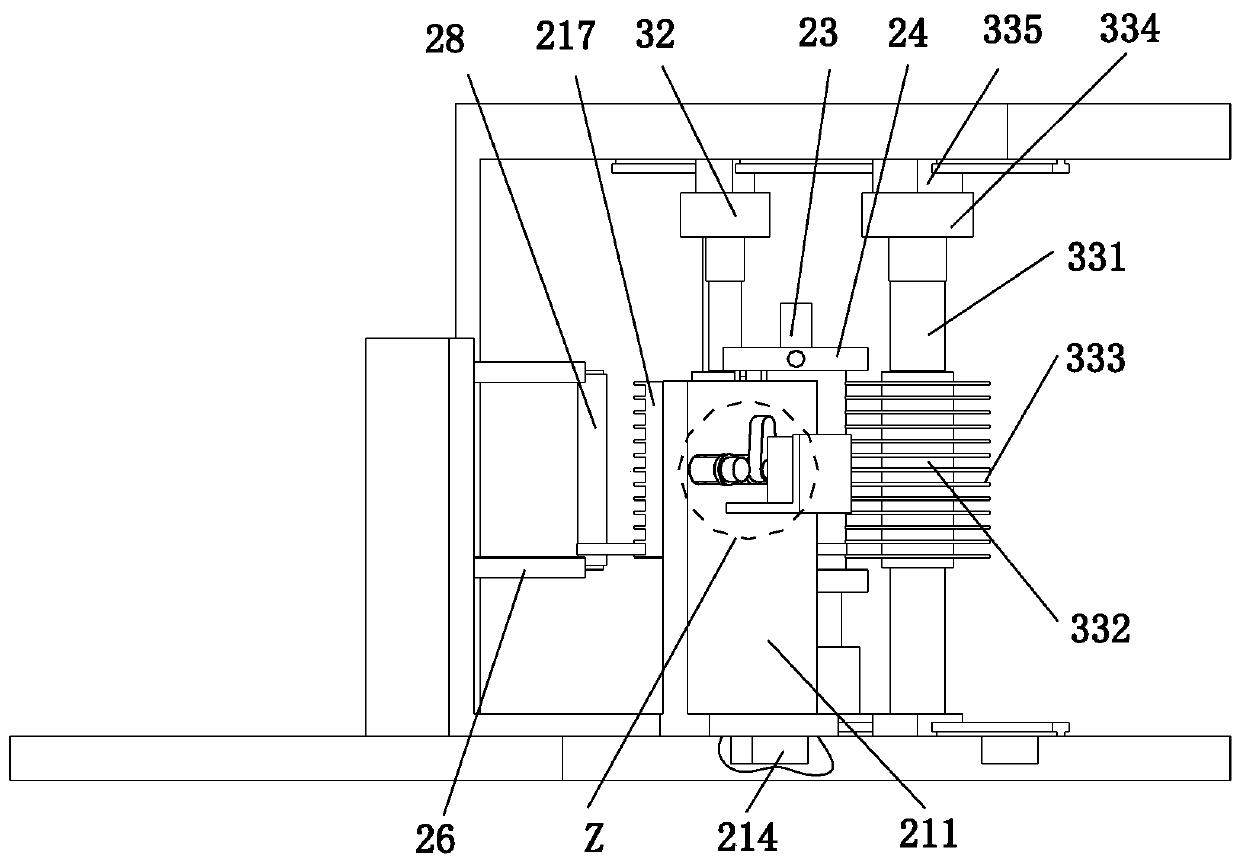

[0031] Such as Figure 1 to Figure 8 As shown, a wire drawing processing machine for making woven bags includes a workbench 1, a clamping device 2 and a cutting device 3. The middle part of the upper end surface of the workbench 1 is equipped with a clamping device 2 through a sliding fit. The left end of the roll device 2 is provided with a cutting device 3, and the lower end of the cutting device 3 and the upper end surface of the workbench 1 are in a sliding fit.

[0032] The clamping device 2 includes an L-shaped electric skateboard 21, a No. 1 motor 22, a fixed shaft 23, a circular support plate 24, a bayonet pin 25, a telescopic plate 26, a clamp post 27 and a reel 28, and the lower end of the L-shaped electric skateboard 21 It is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com