Thermal visbreaking protective film and preparation method thereof

A composition and substance technology, applied in the field of thermal viscosity reduction protective film and its preparation, can solve the problems of difficult peeling strength, damage to components, etc., and achieve the effect of achieving adhesiveness, high adhesiveness and high peeling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

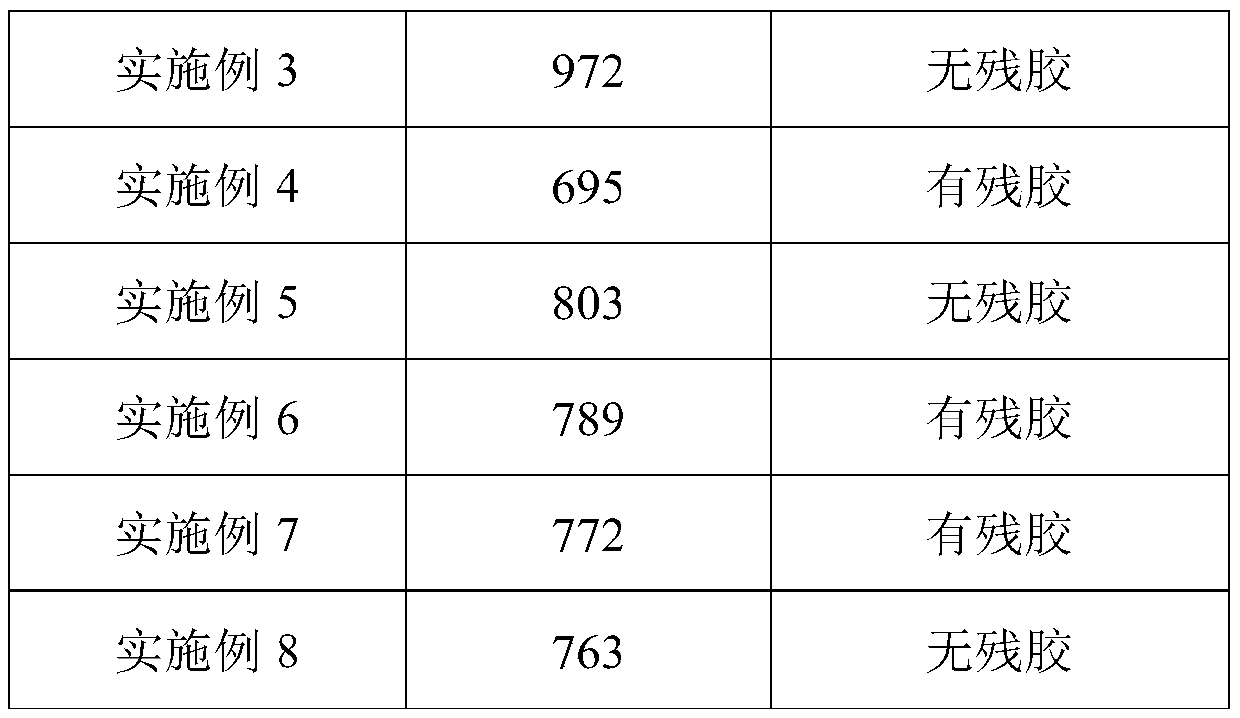

Examples

preparation example Construction

[0030] The preparation method of above-mentioned thermal visbreaking composition is as follows:

[0031] Stir the expansion material and the solvent for 20-30 minutes first, then add the curing agent and acrylic material and stir for 20-30 minutes to obtain the product.

[0032] The second aspect of the present invention provides a thermal detackification protective film, which sequentially includes a substrate layer and a thermal detackification layer, wherein the thermal detackification layer is prepared from the thermal detackification composition.

[0033] In one embodiment, the thickness of the adhesive layer is 20-45 μm.

[0034] In one embodiment, the thickness of the substrate layer is 30-60 μm.

[0035] The base material layer of the present invention can be selected from the materials of those skilled in the art resin, such as but not limited to: low-density polyethylene, medium-density polyethylene, high-density polyethylene, ultra-low-density polyethylene, random ...

Embodiment 1

[0038] Embodiment 1 of the present invention provides a thermal detackification protective film, comprising a substrate layer and a thermal detackification layer in sequence, wherein the thermal detackification layer is prepared from a thermal detackification composition; the thermal detackification composition comprises the following weight Parts of raw materials: 26 parts of acrylate, 21 parts of solvent, 5 parts of curing agent and 6 parts of expansion material;

[0039] The thermal visbreaking composition also includes a thermal initiator, and the content of the thermal initiator is 0.6 wt% of the acrylate monomer content;

[0040] Acrylic substances include polyacrylate substances and acrylate monomers; the weight ratio of polyacrylate substances and acrylate monomers is 0.12:1;

[0041] The acrylate monomers are hydroxyethyl acrylate, lauryl acrylate and 1,6-hexanediol diacrylate, and the molar ratio of hydroxyethyl acrylate, lauryl acrylate and 1,6-hexanediol diacrylate...

Embodiment 2

[0050] Embodiment 2 of the present invention provides a thermal detackification protective film, comprising a substrate layer and a thermal detackification layer in sequence, wherein the thermal detackification layer is prepared from a thermal detackification composition; the thermal detackification composition comprises the following weight Parts of raw materials: 44 parts of acrylate, 33 parts of solvent, 12 parts of curing agent and 12 parts of expansion material;

[0051] The thermal visbreaking composition also includes a thermal initiator, and the content of the thermal initiator is 2.8 wt% of the acrylate monomer content;

[0052] Acrylic substances include polyacrylate substances and acrylate monomers; the weight ratio of polyacrylate substances and acrylate monomers is 0.31:1;

[0053] The acrylate monomers are hydroxyethyl acrylate, lauryl acrylate and 1,6-hexanediol diacrylate, and the molar ratio of hydroxyethyl acrylate, lauryl acrylate and 1,6-hexanediol diacryla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com