Nano mesoporous bioactive glass and preparation method thereof

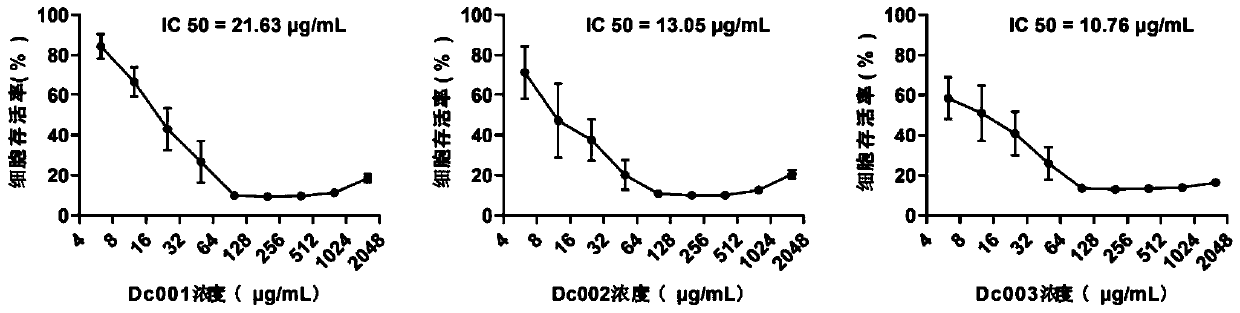

A bioactive glass and nano-mesoporous technology, applied in the field of biomedical materials, can solve the problems of single material performance, lack of antibacterial properties, and difficult product particle size, and achieve excellent antibacterial performance, good durability, and high stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

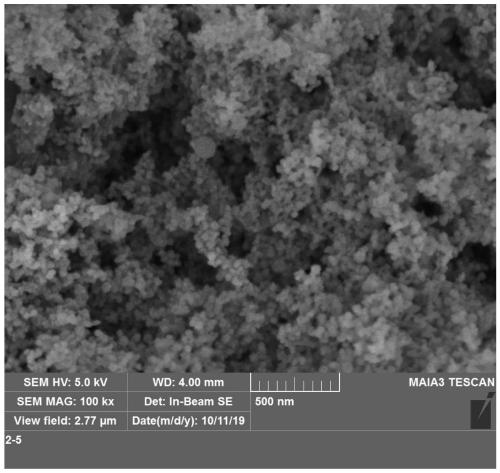

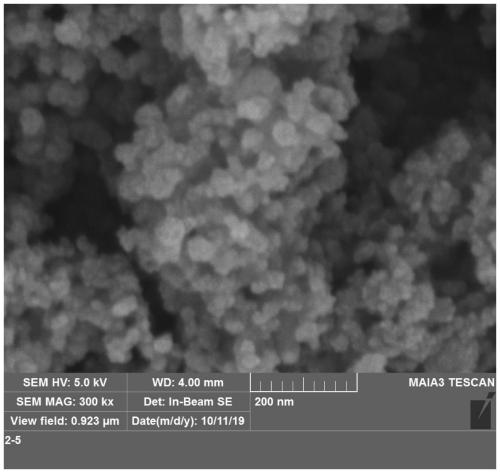

Image

Examples

Embodiment 1

[0049] A kind of nano mesoporous bioactive glass, its preparation method is as follows:

[0050] (1) 500.05g water, 511.07g ethanol, 8.15g dioctadecyl dimethyl ammonium chloride and 4.14g triethanolamine are successively added into a beaker to form a mixed solution, and the pH value of the mixed solution is 10;

[0051] Then 34.72g tetraethyl orthosilicate, 5.06g triethyl phosphate, 18.41g calcium nitrate tetrahydrate and 0.44g nano-zinc oxide were added to the above mixed solution in sequence, and after stirring evenly, the precursor of nano-mesoporous bioactive glass was obtained. Biosol;

[0052] (2) Take out the precursor sol obtained in step (1) and seal it well, put it in an oven at 60°C for aging for 1 day; then place it in an oven at 120°C for 3 days to obtain dried nano-mesoporous organisms Active glass precursor powder;

[0053] (3) Place the obtained precursor powder in a high-temperature furnace and heat-treat at a temperature of 600° C. for 5 hours to obtain the...

Embodiment 2

[0055] A kind of nano mesoporous bioactive glass, its preparation method is as follows:

[0056] (1) 500.06g water, 511.03g ethanol, 3.26g dioctadecyl dimethyl ammonium chloride and 2.07g triethanolamine are successively added into a beaker to form a mixed solution, and the pH value of the mixed solution is 10;

[0057] Then 3.34g of white carbon black, 0.63g of triethyl phosphate, 2.66g of calcium chloride and 0.21g of nano-zinc oxide were added to the above-mentioned mixed solution, and after stirring evenly, the precursor sol of nano-mesoporous bioactive glass was obtained;

[0058] (2) Take out the precursor sol obtained in step (1) and seal it well, put it in an oven at 70°C for aging for 1 day; then place it in an oven at 90°C to dry for 3 days, and obtain the dried nano-mesoporous organism Active glass precursor powder;

[0059] (3) Place the obtained precursor powder in a high-temperature furnace and heat-treat at a temperature of 700° C. for 3 hours to obtain the nan...

Embodiment 3

[0061] A kind of nano mesoporous bioactive glass, its preparation method is as follows:

[0062] (1) 500.09g water, 511.02g ethanol, 6.51g dioctadecyl dimethyl ammonium chloride and 3.32g triethanolamine are successively added into a beaker to form a mixed solution, and the pH value of the mixed solution is 10;

[0063] Then 31.58g of sodium silicate, 1.42g of triethyl phosphate, 16.74g of calcium nitrate tetrahydrate and 0.16g of nano-zinc oxide were added to the above mixed solution in sequence, and after stirring evenly, the precursor sol of nano-mesoporous bioactive glass was obtained. ;

[0064] (2) Take out the precursor sol obtained in step (1) and seal it well, put it in an oven at 80°C and age it for 1 day; then place it in an oven at 100°C and dry it for 3 days to obtain the dried nano-mesoporous organism Active glass precursor powder;

[0065] (3) The obtained precursor powder is placed in a high-temperature furnace, and heat-treated at a temperature of 800° C. fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com