Pressing duplex gear tooth groove centering grinding method

A double gear and grinding technology, applied in the direction of gear teeth, belts/chains/gears, components with teeth, etc., can solve the problems of difficult to achieve center coincidence requirements and reduce the accuracy requirements of disc gears before grinding. , to achieve the effect of reducing scrap rate and reliable control of processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

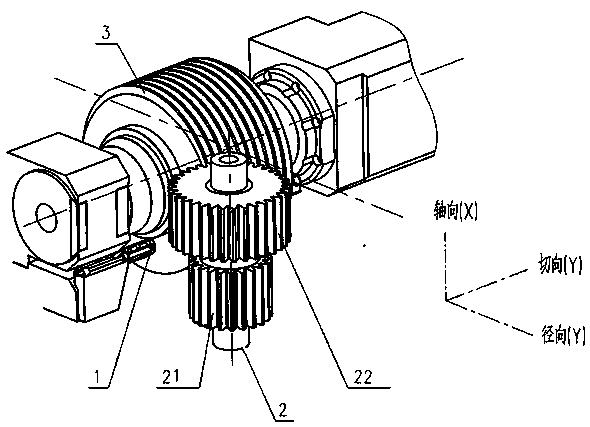

[0024] The scheme will be further described below in conjunction with the accompanying drawings.

[0025] The high-precision non-contact tooth-aligning probe 1 is installed on one end of the 3-axis of the grinding wheel, so it can move along the radial, tangential, and axial directions of the workpiece with the help of the linear motion axis of the machine tool; the shaft gear 21 has been ground to the size required by the drawing and precision, press-fit the unground disc gear 22 to the shaft gear 21 to form the press-fit duplex gear 2, and mark the overlapped tooth slot positions during the press-fit.

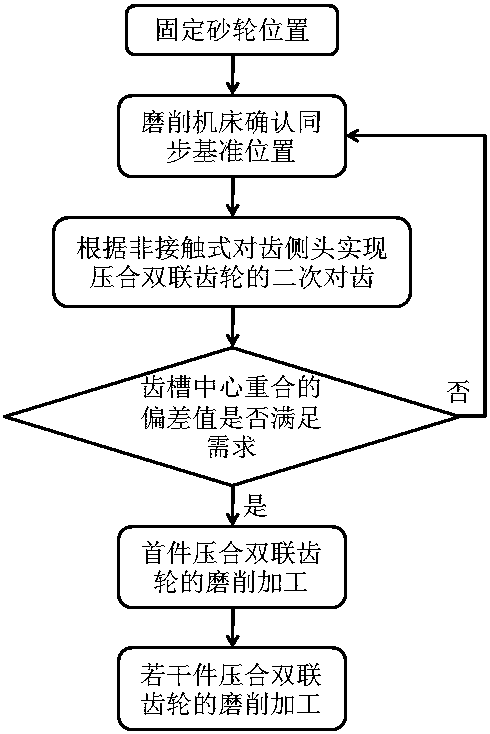

[0026] A method for centering grinding of two tooth slots of a press-fit double gear, comprising the following steps:

[0027] Step A. Fix the position of the grinding wheel 3 according to the slot marked during pressing: snap the tooth body of the grinding wheel 3 into the slot in the press-fit double gear 2, and the slot is the middle plate gear 22 of the press-fit double g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com