Method for suppressing radio frequency loss of silicon-based gallium nitride radio frequency device

A radio frequency device, silicon-based nitrogen technology, applied in semiconductor/solid state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of increasing the conductivity of silicon substrates, large radio frequency loss of microwave radio frequency devices, etc., to reduce radio frequency loss, The effect of reducing conductivity, the method is simple, fast and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

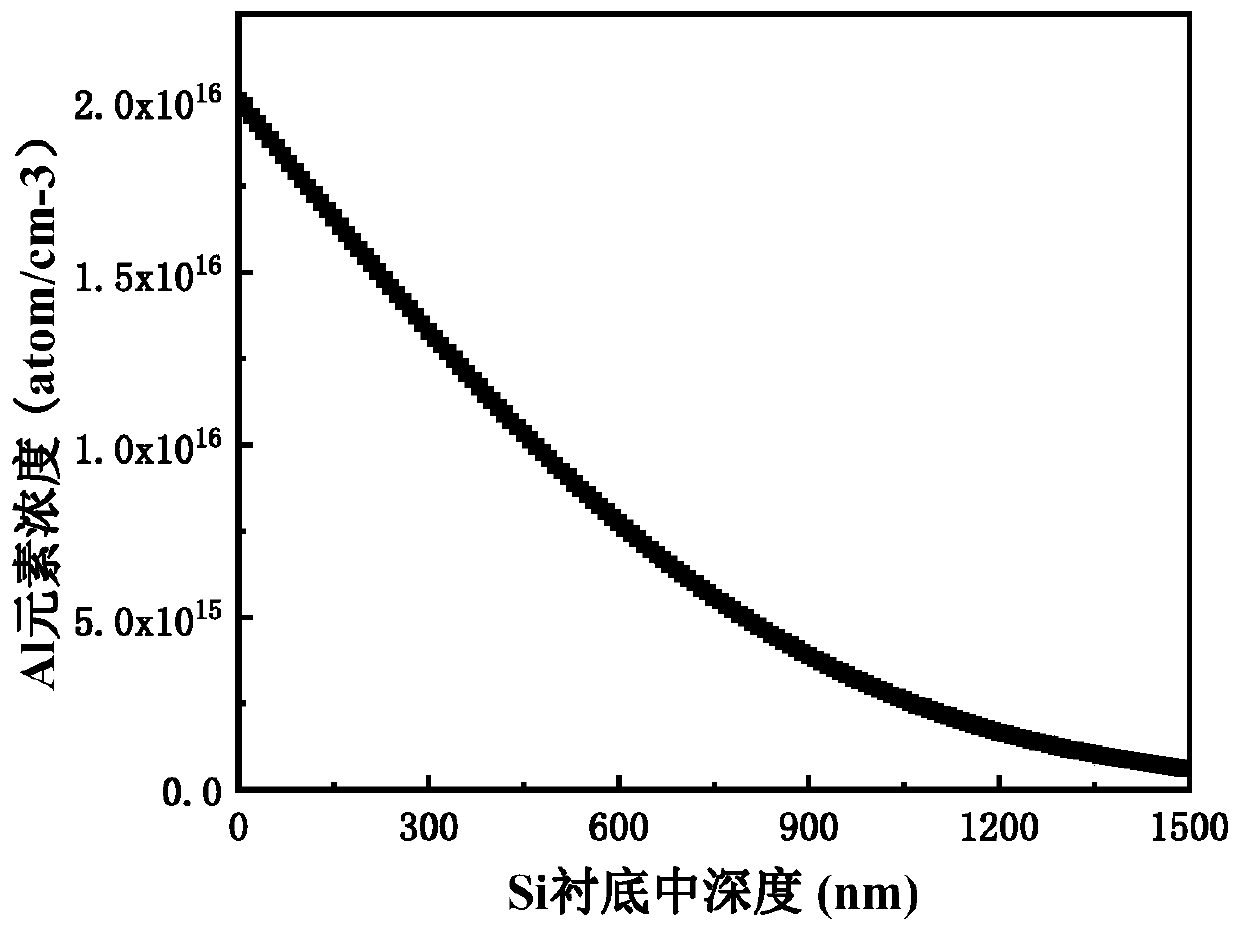

[0026] The key of the present invention is to perform pretreatment on the high-resistance silicon substrate in advance, and before epitaxial nitride, a layer of n-type single crystal silicon doped with phosphorus is epitaxially grown on the silicon substrate. The carrier concentration in single-crystal silicon needs to be controlled to match the estimated hole concentration distribution due to the diffusion of aluminum atoms.

[0027] Attached below figure 1 , the present invention will be further described by embodiment.

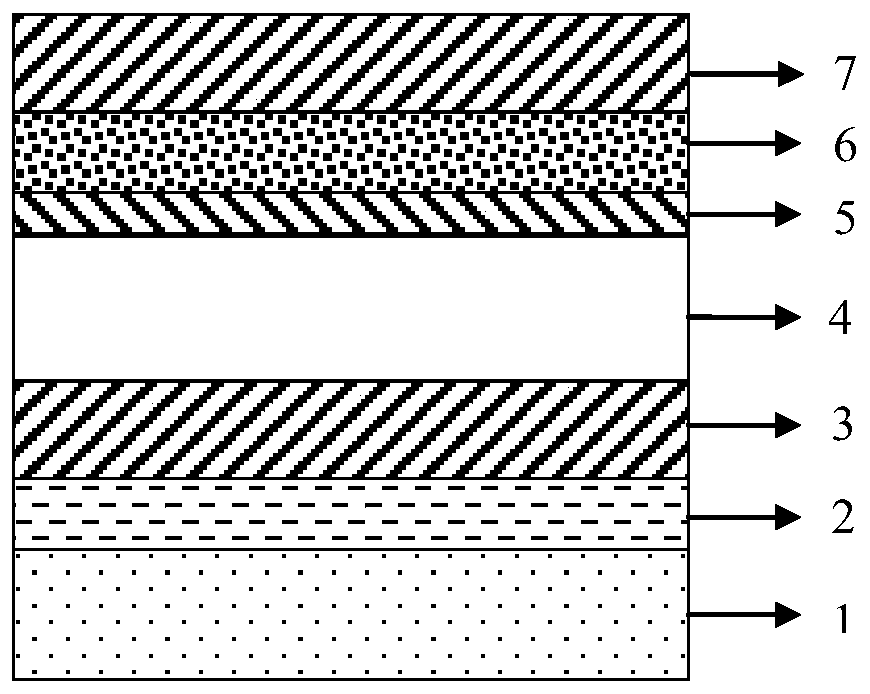

[0028] The structure of the silicon-based gallium nitride radio frequency device prepared in this embodiment is as follows figure 1 As shown, it includes a high-resistance silicon substrate and a phosphorus-doped n-type single-crystal silicon epitaxial layer 2, an aluminum nitride nucleation layer 3, an aluminum gallium nitrogen stress buffer layer 4, and a gallium nitride epitaxial layer sequentially stacked on the high-resistance silicon substrate. 5. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com