Method and system for evaluating performance of sintering process based on time series feature extraction

A technology for operating performance and feature extraction, which is applied in manufacturing computing systems, neural learning methods, data processing applications, etc., and can solve problems such as difficulty in evaluating operating performance during sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the specific embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

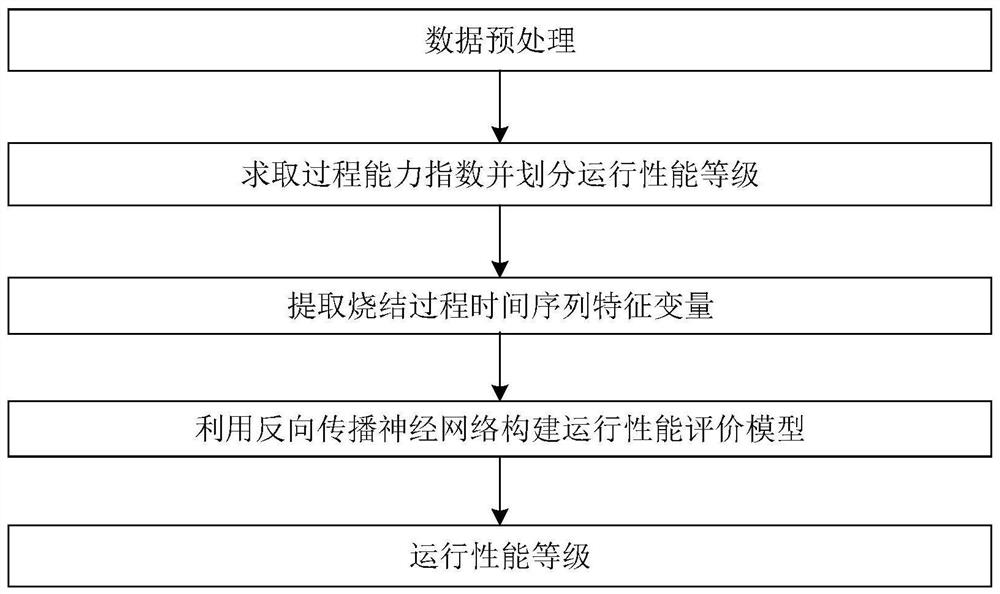

[0051] The performance evaluation method of sintering process based on time series feature extraction, such as figure 1 shown, including

[0052] Step 1: Preprocess the time series data of the sintering end point and the time series data of the detection parameters;

[0053] Step 2: Taking the sintering end point as the decision parameter, the process capability index is obtained, and based on this, the operation performance level of the sintering process is divided;

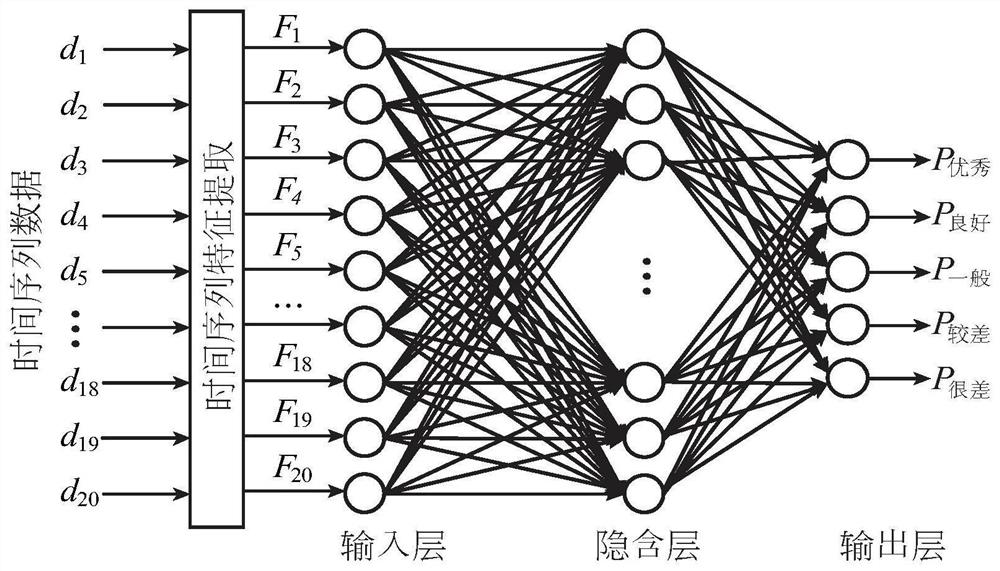

[0054] Step 3: Extract four characteristic variables of each detection parameter time series in the sintering process, which are mean value, standard deviation, mean absolute error and trend characteristics;

[0055] Step 4: Use the four characteristic variables of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com