Conjoined reaction type reactive acrylic resin waterproof coating and coating method thereof

A technology of acrylic resin and waterproof coating, which is applied to coatings, devices for coating liquid on the surface, and special surfaces, etc. It can solve problems such as easy peeling off of the coating, cracking of the waterproof layer, and large impact on the waterproof layer, so as to improve the adhesion of the adhesive. Excellent bonding strength and toughness, improved adhesion, and excellent waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

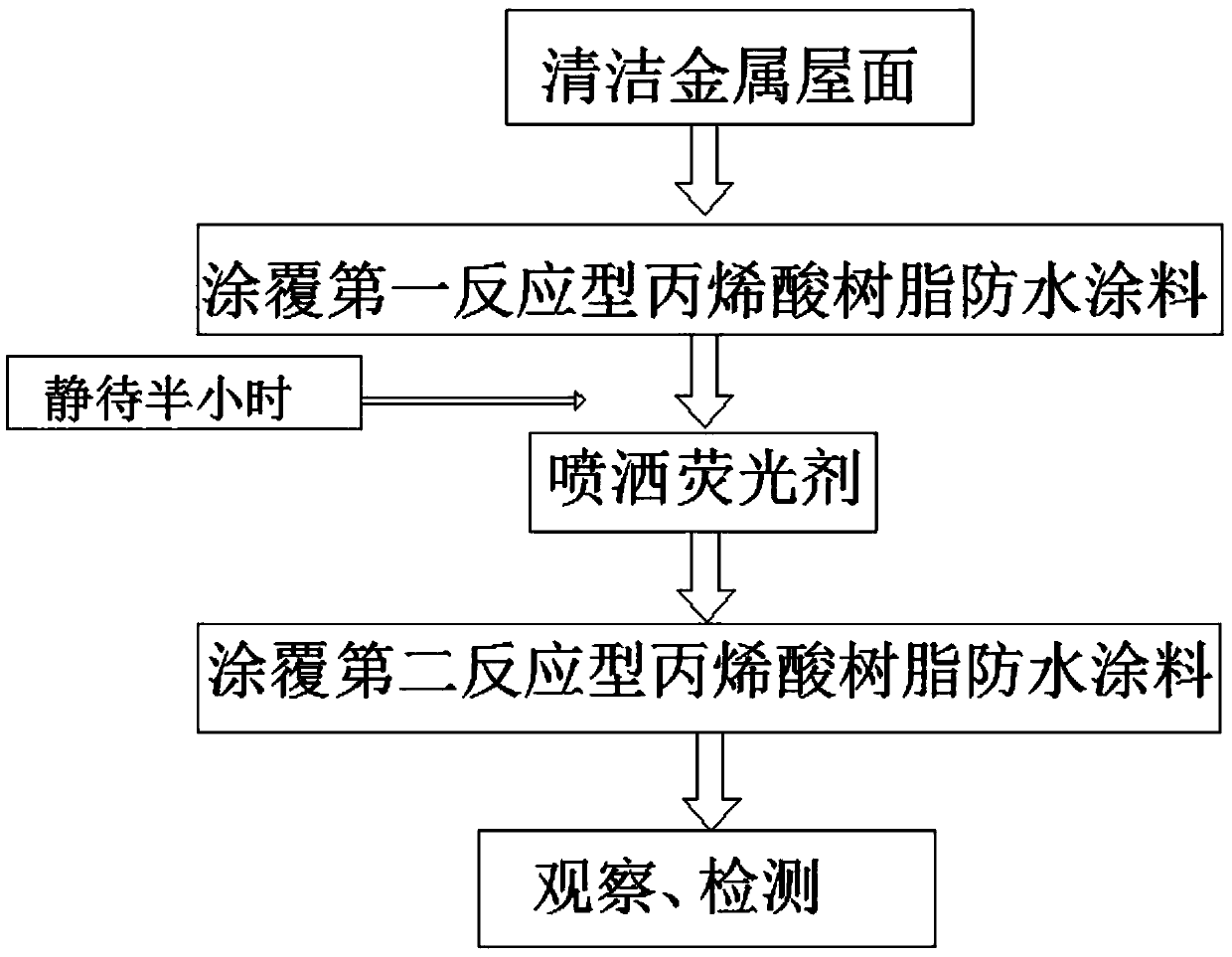

Image

Examples

Embodiment 1

[0047] A conjoined reaction type reactive acrylic resin waterproof coating, comprising a first reactive acrylic resin waterproof coating and a second reactive acrylic resin waterproof coating, the main component ratio of the first reactive acrylic resin waterproof coating is as follows:

[0048] 30 parts of butyl methacrylate;

[0049] 18 parts of butyl acrylate;

[0050] 13 parts of isooctyl acrylate;

[0051] 1 part of triethylene glycol diacrylate;

[0052] 15 parts of aliphatic elastic polyurethane resin;

[0053] 1 part of meteorological silica anti-sedimentation agent;

[0054] 5 parts of rutile titanium dioxide;

[0055] 20 parts of heavy calcium carbonate;

[0056] 0.5 parts of N,N-dimethyl-p-aniline;

[0057] 2 parts of dibenzoyl peroxide powder;

[0058] 3 parts polycarbonate;

[0059] 1 part polyamide;

[0060] Micro Repair Balls 10 servings.

[0061] The main component ratio of the second reaction type acrylic resin waterproof coating is as follows:

[0...

Embodiment 2

[0075] A conjoined reaction type reactive acrylic resin waterproof coating, comprising a first reactive acrylic resin waterproof coating and a second reactive acrylic resin waterproof coating, the main component ratio of the first reactive acrylic resin waterproof coating is as follows:

[0076] 25 parts of butyl methacrylate;

[0077] 20 parts of butyl acrylate;

[0078] 10 parts of isooctyl acrylate;

[0079] 2 parts of tetraethylene glycol diacrylate;

[0080] 18 parts of aliphatic elastic polyurethane resin;

[0081] 0.5 parts of meteorological silica anti-sedimentation agent;

[0082] 7 parts of rutile titanium dioxide;

[0083] 22 parts of heavy calcium carbonate;

[0084] 0.8 parts of N, N-dimethyl-p-aniline;

[0085] 1 part of dibenzoyl peroxide powder;

[0086] 3.5 parts of polycarbonate;

[0087] 2 parts polyamide;

[0088] Micro Repair Balls 10 servings.

[0089] The main component ratio of the second reaction type acrylic resin waterproof coating is as fo...

Embodiment 3

[0103] A conjoined reaction type reactive acrylic resin waterproof coating, comprising a first reactive acrylic resin waterproof coating and a second reactive acrylic resin waterproof coating, the main component ratio of the first reactive acrylic resin waterproof coating is as follows:

[0104] 20 parts of butyl methacrylate;

[0105] 15 parts of butyl acrylate;

[0106] 12 parts of isooctyl acrylate;

[0107] 2 parts of tetraethylene glycol diacrylate;

[0108] 20 parts of aliphatic elastic polyurethane resin;

[0109] 1.5 parts of meteorological silica anti-sedimentation agent;

[0110] 8 parts of rutile titanium dioxide;

[0111] 25 parts of heavy calcium carbonate;

[0112] 1 part of N,N-dimethyl-p-aniline;

[0113] 1.5 parts of dibenzoyl peroxide powder;

[0114] 4 parts polycarbonate;

[0115] 4 parts polyamide;

[0116] Micro Repair Balls 10 servings.

[0117] The main component ratio of the second reaction type acrylic resin waterproof coating is as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com