Preparation method of baking-free high-strength fly ash ceramsite

A technology of fly ash ceramsite and fly ash, which is applied in the field of preparation of unburned high-strength fly ash ceramsite, can solve the problem of high cost of sintered fly ash ceramsite, low strength of unburned fly ash ceramsite, and market Problems such as high price, to achieve the effect of broadening joint utilization, reducing preparation cost, and simple molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

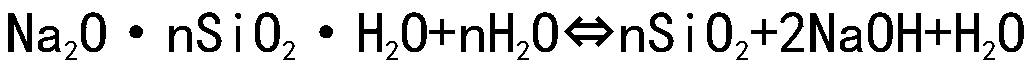

Method used

Image

Examples

Embodiment 1

[0058] A preparation method of high-strength unburned fly ash ceramsite, the mass ratio of each raw material is as follows:

[0059] 2190 parts of secondary fly ash, 90 parts of quicklime, 60 parts of desulfurized gypsum, 390 parts of ordinary 425 Portland cement, 55 parts of instant sodium silicate;

[0060] A preparation method of high-strength unburned fly ash ceramsite, the preparation steps are as follows:

[0061] 1. First weigh 10% of the total amount of fly ash, that is, 219 parts of fly ash and 60 parts of gypsum, put them in an oven for quick drying, and then weigh 90 parts of quicklime and the prepared fly ash and gypsum , into a high-speed pulverizer, pulverized for 5 minutes;

[0062] 2. Weigh 1971 parts of fly ash and 390 parts of ordinary 425 Portland cement, and put them into the bucket;

[0063] 3. Mix the prepared mixed alkaline activator with the prepared raw materials evenly, and divide it into two parts, one part is 2550 parts, and the other part is 180 ...

Embodiment 2

[0068] A preparation method of high-strength unburned fly ash ceramsite, the mass ratio of each raw material is as follows:

[0069] 2190 parts of secondary fly ash, 90 parts of quicklime, 60 parts of desulfurized gypsum, 390 parts of ordinary 425 Portland cement in two parts, one part of 210 parts, one part of 180 parts, and 55 parts of instant sodium silicate;

[0070] A preparation method of high-strength unburned fly ash ceramsite, the preparation steps are as follows:

[0071] 1. First weigh 10% of the total amount of fly ash, that is, 219 parts of fly ash and 60 parts of gypsum, put them in an oven for quick drying, and then weigh 90 parts of quicklime and the prepared fly ash and gypsum , into a high-speed pulverizer, pulverized for 5 minutes;

[0072] 2. Weigh 1971 parts of fly ash and 210 parts of ordinary 425 portland cement, and put them into the bucket;

[0073] 3. Mix the prepared mixed alkaline activator with the prepared raw materials evenly;

[0074] 4. Take...

Embodiment 3

[0078] A method for preparing high-strength unburned fly ash ceramsite, the mass ratio of each raw material is as follows:

[0079] 2400 parts of secondary fly ash, 90 parts of quicklime, 60 parts of desulfurized gypsum, 450 parts of ordinary 425 Portland cement, divided into two parts, one part 255 parts, one part 195 parts, 60 parts instant sodium silicate;

[0080] A method for preparing high-strength unburned fly ash ceramsite, the preparation steps are as follows:

[0081] 1. First weigh 10% of the total amount of fly ash, that is, 240 parts of fly ash and 60 parts of gypsum, put them in an oven for quick drying, and then weigh 90 parts of quicklime and the prepared fly ash and gypsum , into a high-speed pulverizer, pulverized for 5 minutes;

[0082] 2. Weigh 2160 parts of fly ash and 255 parts of ordinary 425 portland cement, and put them into the bucket;

[0083] 3. Mix the prepared mixed alkaline activator with the prepared raw materials evenly;

[0084] 4. Weigh 2%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com