Ivory white ceramic glaze with self-cleaning function and preparation method of ivory white ceramic glaze

A ceramic glaze and functional technology, applied in the field of ivory white ceramic glaze and its preparation, can solve the problems of insignificant self-cleaning function effect, single gloss, stained with stains, etc. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

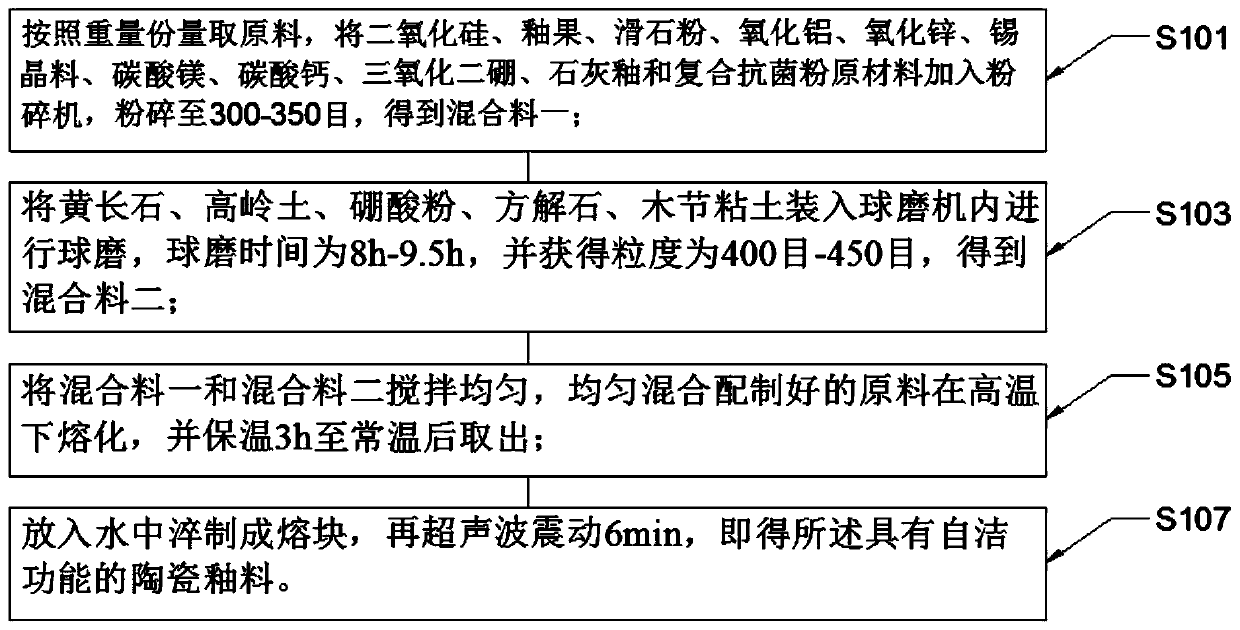

Method used

Image

Examples

Embodiment 1

[0030] An ivory white ceramic glaze with self-cleaning function, comprising the following raw materials in parts by mass: 25 parts of silicon dioxide, 20 parts of feldspar, 20 parts of kaolin, 10 parts of boric acid powder, 10 parts of calcite, 15 parts of wood knot clay, 15 parts of glaze fruit, 10 parts of talcum powder, 15 parts of aluminum oxide, 2 parts of zinc oxide, 2 parts of tin crystal material, 2 parts of magnesium carbonate, 1 part of calcium carbonate, 0.8 parts of diboron trioxide, 2 parts of lime glaze and compound antibacterial Powder, the composite antibacterial powder is a mixture of 20 parts of titanium dioxide, 20 parts of silver molybdate and 60 parts of ammonium dihydrogen phosphate.

Embodiment 2

[0032] An ivory white ceramic glaze with self-cleaning function, comprising the following raw materials in parts by mass: 30 parts of silicon dioxide, 25 parts of feldspar, 22 parts of kaolin, 12 parts of boric acid powder, 12 parts of calcite, 17 parts of wood knot clay, 17 parts of glaze fruit, 15 parts of talcum powder, 17 parts of aluminum oxide, 4 parts of zinc oxide, 3 parts of tin crystal material, 3 parts of magnesium carbonate, 2 parts of calcium carbonate, 1.2 parts of diboron trioxide, 3 parts of lime glaze and compound antibacterial Powder, the composite antibacterial powder is a mixture of 25 parts of titanium dioxide, 25 parts of silver molybdate and 50 parts of ammonium dihydrogen phosphate.

Embodiment 3

[0034] An ivory white ceramic glaze with self-cleaning function, comprising the following raw materials in parts by mass: 32 parts of silicon dioxide, 28 parts of feldspar, 23 parts of kaolin, 14 parts of boric acid powder, 14 parts of calcite, 19 parts of wood knot clay, 19 parts of glaze fruit, 18 parts of talcum powder, 19 parts of aluminum oxide, 6 parts of zinc oxide, 4 parts of tin crystal material, 4 parts of magnesium carbonate, 3 parts of calcium carbonate, 1.6 parts of diboron trioxide, 4 parts of lime glaze and compound antibacterial Powder, the composite antibacterial powder is a mixture of 28 parts of titanium dioxide, 28 parts of silver molybdate and 44 parts of ammonium dihydrogen phosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com