Powder grinding machine for preparing calcium carbonate powder

A technology of calcium carbonate powder and milling machine, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, grain processing, etc. It can solve the problems of prolonging the grinding time, uneven grinding surface, and non-storage of grinding, so as to achieve prolonged grinding the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

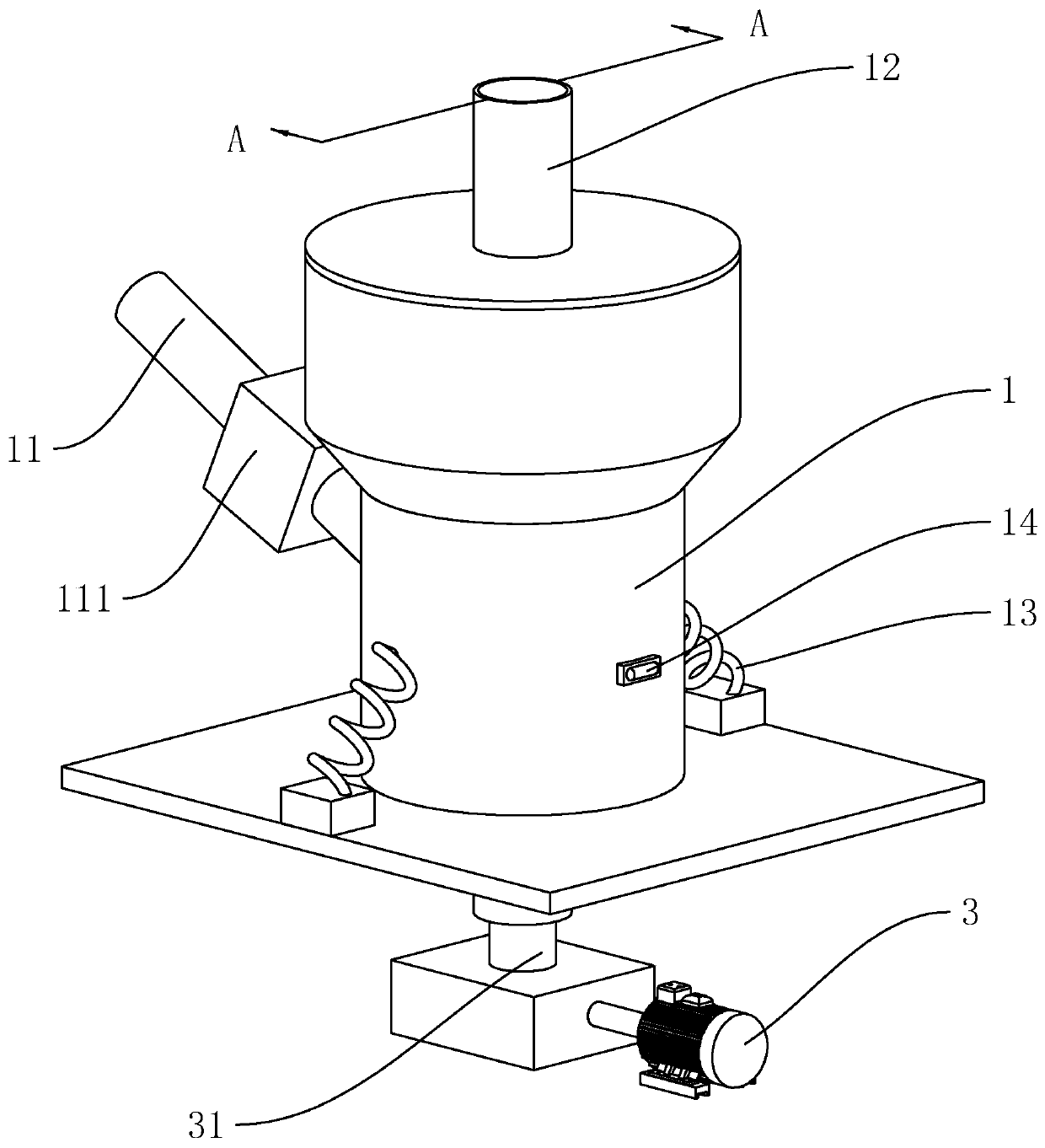

[0036] refer to figure 1 , is a milling machine for preparing calcium carbonate powder disclosed by the present invention, which includes a main body 1, the inside of which is a crushing chamber, and the main body 1 is provided with a feed port 11 and a discharge port 12.

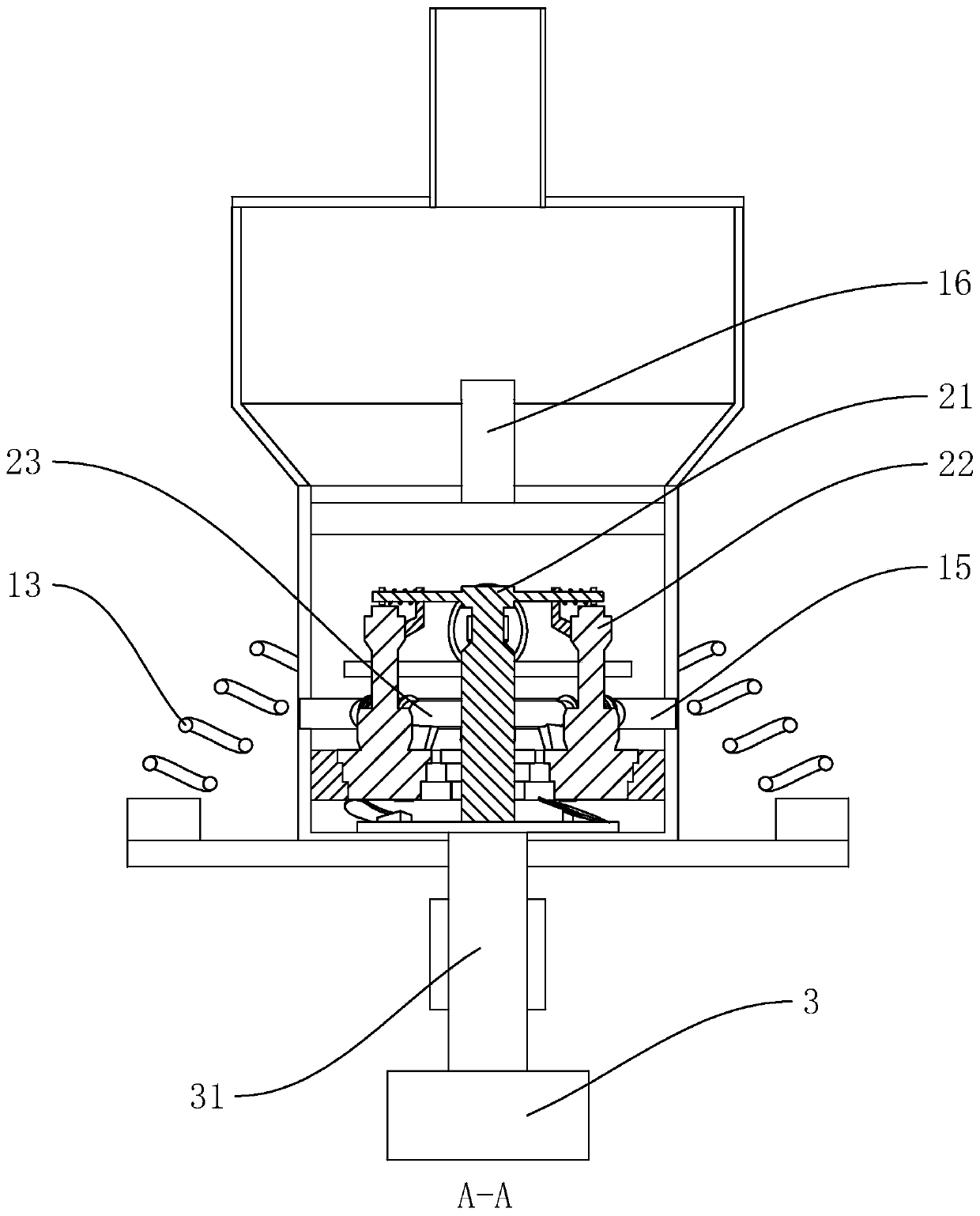

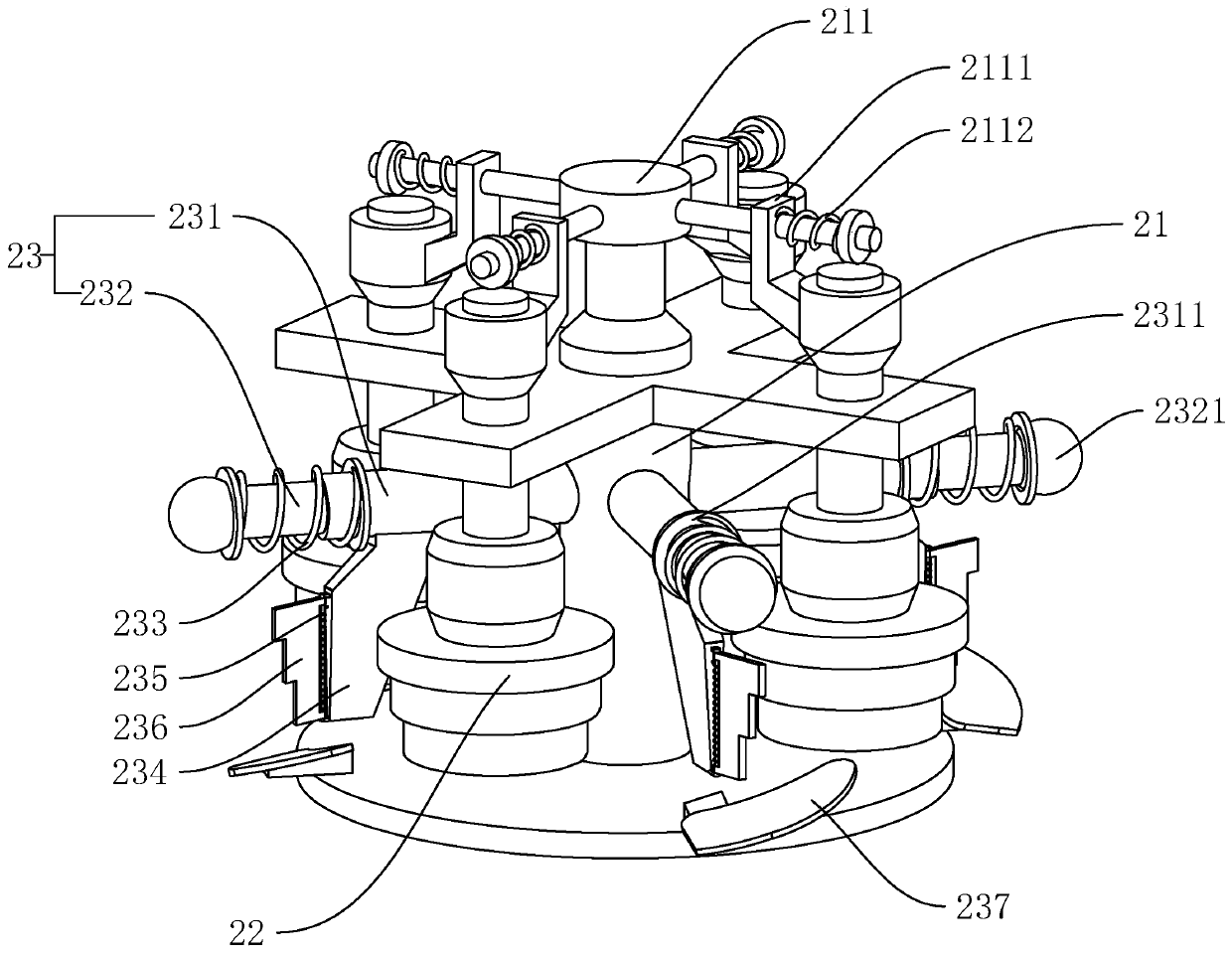

[0037] refer to figure 2 as well as image 3 , the inside of the main body 1 is provided with a grinding assembly 2, and the grinding assembly 2 includes a main shaft 21, several grinding rollers 22 and a driving member for driving the main shaft 21 to rotate; At the center position, the grinding roller 22 is installed on the main shaft 21 and distributed at intervals; the position inside the main body 1 that fits the grinding roller 22 is the grinding surface, and the main shaft 21 is equipped with a scraper 236 that fits the grinding surface. In this embodiment, the grinding surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com