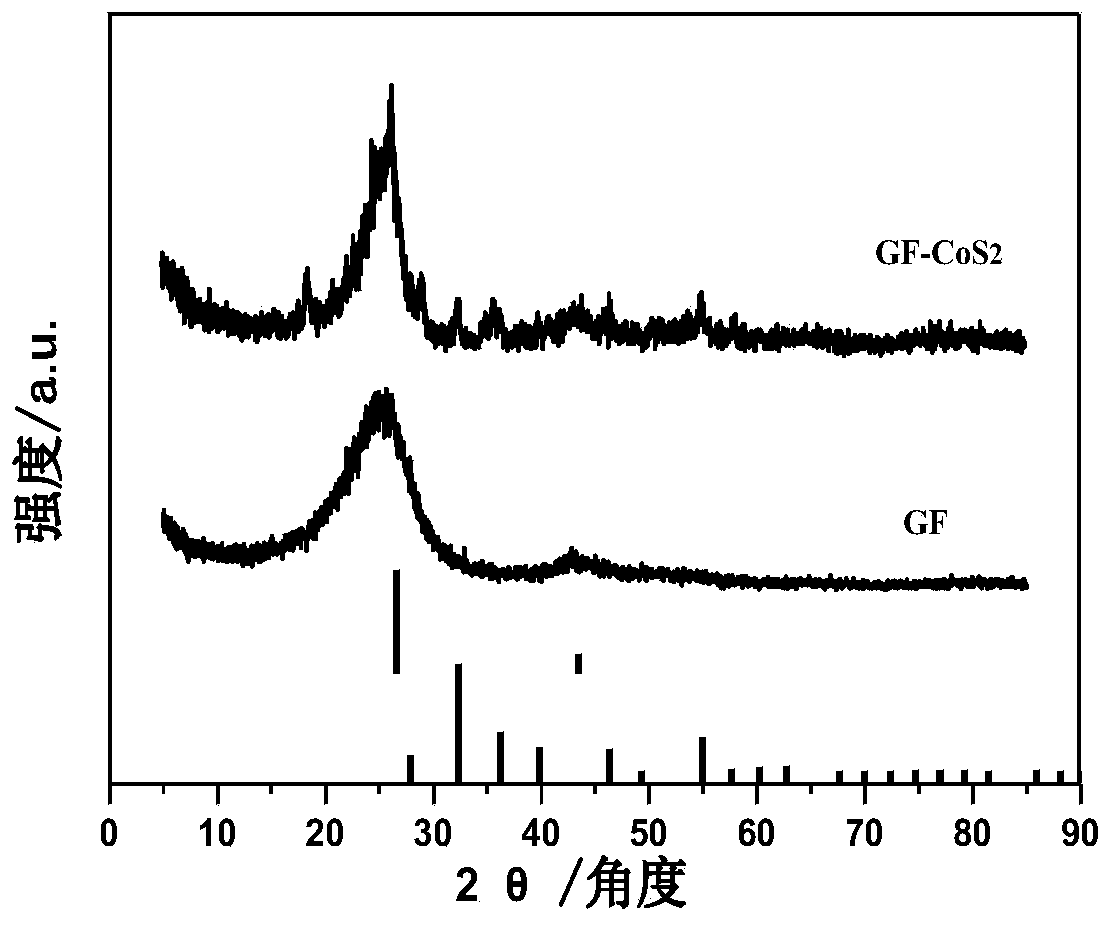

Preparation method and application of cobalt disulfide/carbon fiber composite material

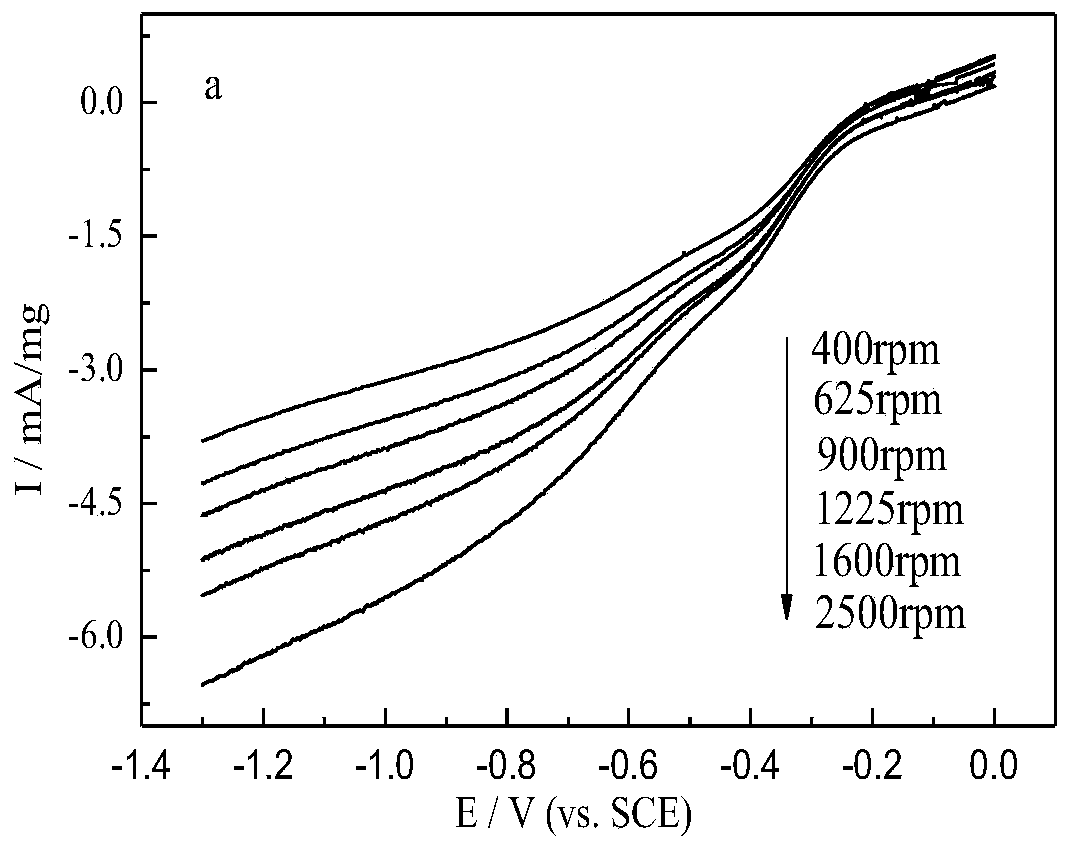

A composite material, cobalt disulfide technology, applied in chemical instruments and methods, chemical/physical processes, oxidized water/sewage treatment, etc., can solve the problems of high temperature required, complicated preparation process of cobalt disulfide, etc., and achieve the reaction conditions Mild and controllable, short cycle, simple and safe preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

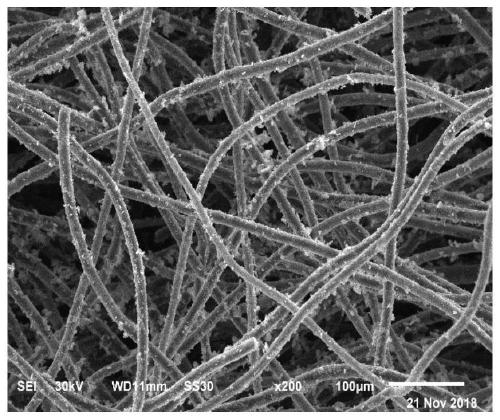

[0034] Cut a polyacrylonitrile carbon felt with a length of 4cm, a width of 3cm, and a thickness of 0.5cm, wash and dry in acetone, ethanol, and deionized water in sequence; prepare a 0.6mol / L urea solution under magnetic stirring conditions, and transfer it to the reaction In the kettle, the hydrothermal temperature is 120° C., and the reaction time is 20 h, and nitriding treatment is carried out to obtain nitrided carbon fibers.

[0035] Weigh cobalt chloride, sodium thiosulfate and sublimed sulfur, control the total mole of cobalt ion salt, sodium thiosulfate and sublimated sulfur to be 0.03mol, and the molar ratio of cobalt ion salt, sulfur salt and sublimated sulfur to be 1:1:1 , was dissolved in 50mL ultrapure water, and stirred for 40min to obtain a mixed solution.

[0036] Immerse the carbon nitride fiber material in the above solution, and transfer it to the reaction kettle after immersion for 20 minutes. Drying for 24 hours under high temperature to obtain a cobalt ...

Embodiment 2

[0038] Cut an activated carbon felt with a length of 6 cm, a width of 5 cm, and a thickness of 1 cm, wash and dry in acetone, ethanol, and deionized water in sequence; configure a 1.8 mol / L urea solution under magnetic stirring conditions, and transfer it to a reaction kettle, water The heating temperature is 160° C., the reaction time is 12 hours, and nitriding treatment is performed to obtain nitrided carbon fibers.

[0039] Take cobalt sulfate, sodium thiosulfate and sublimation sulfur, control the total mole of cobalt ion salt, sodium thiosulfate and sublimation sulfur to be 0.03mol, and the mol ratio of cobalt ion salt, sulfur salt and sublimation sulfur is 1:1:2, It was dissolved in 70mL ultrapure water and stirred for 30min to obtain a mixed solution.

[0040] Immerse the carbon nitride fiber material in the above solution, and transfer it to the reaction kettle after immersion for 30 minutes. Drying for 24 hours under high temperature to obtain a cobalt disulfide / carb...

Embodiment 3

[0042] Cut a viscose-based graphite felt with a length of 4 cm, a width of 3 cm, and a thickness of 0.5 cm, wash and dry in acetone, ethanol, and deionized water in sequence; configure a 2.5 mol / L urea solution under magnetic stirring conditions, and transfer it to the reaction In the kettle, the hydrothermal temperature is 200° C., and the reaction time is 8 hours, and nitriding treatment is carried out to obtain nitrided carbon fibers.

[0043] Take cobalt chloride, sodium thiosulfate and sublimation sulfur, control the total mole of cobalt ion salt, sodium thiosulfate and sublimation sulfur to be 0.03mol, and the molar ratio of cobalt ion salt, sulfur salt and sublimation sulfur is 1:1:2 , was dissolved in 80mL ultrapure water, and stirred for 30min to obtain a mixed solution.

[0044]Immerse the carbon nitride fiber material in the above solution, and transfer it to the reaction kettle after immersion for 40 minutes. Drying for 24 hours under high temperature to obtain a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com