Pressure-controllable breathing nose plug and single-pipe breathing machine adopting same

A ventilator and nasal congestion technology, which is applied in the field of medical equipment, can solve the problems of patients' pain, insufficient safety, inconvenient use of oxygen nasal catheter and nasal congestion, etc., and achieve the effect of ensuring airtightness and good airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

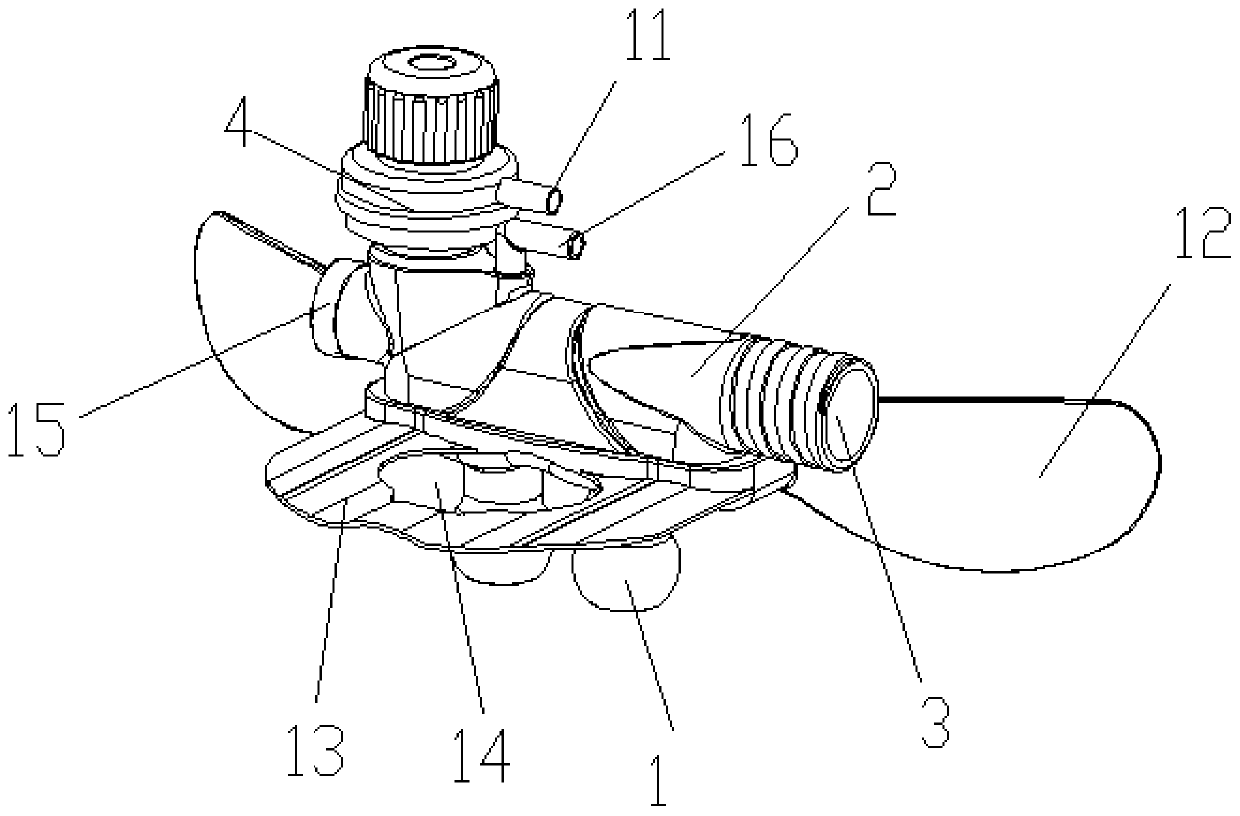

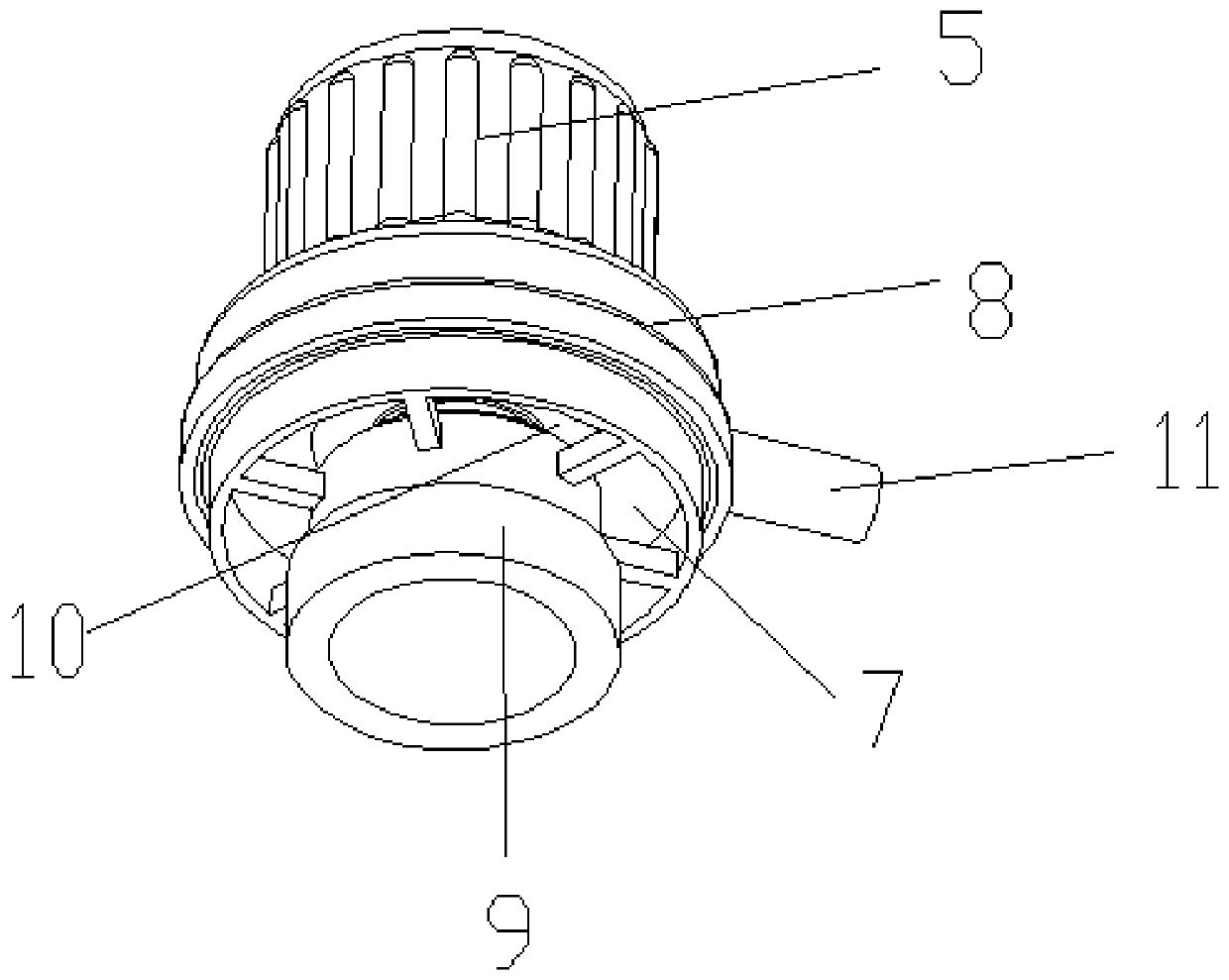

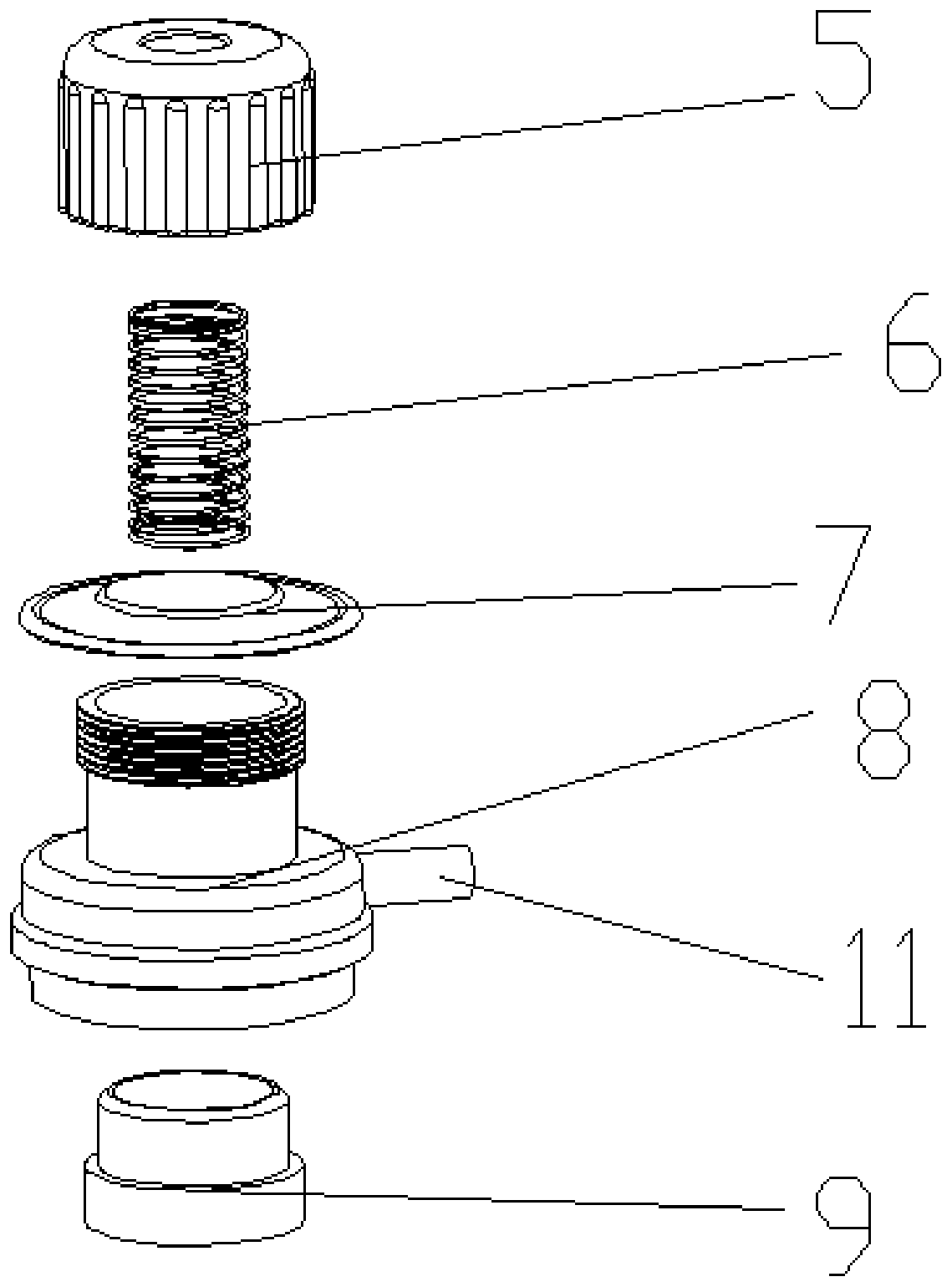

[0028] like Figure 1 to Figure 3 As shown, a pressure-controllable respiratory nasal plug includes a nasal plug head 1 and an air source inlet pipe 2, the air source inlet pipe 2 is provided with an air source input port 3, the number of which is one, and the air source The other end of the access tube 2 is provided with a one-way valve 15. When the nasal plug has a gas supply, the one-way valve 15 is always closed under gas pressure or in a natural state. When the equipment fails, there is no gas supply. Pneumatic action, the one-way valve 15 opens and communicates with the atmosphere to supply air to the patient under a small inspiratory pressure to ensure the patient's aerobic respiration. The air source connection tube 2 is also provided with a test pressure connection port 16 for real-time The air pressure in the pipeline is monitored, and the nasal plug head 1 is connected to the air source connecting pipe 2, and the air source connecting pipe 2 is provided with a fixed...

Embodiment 2

[0031] like Figure 4 As shown, a pressure-controllable respiratory nasal plug includes a nasal plug head 1 and an air source inlet pipe 2, the air source inlet pipe 2 is provided with an air source input port 3, the number of which is one, and the air source The other end of the access tube 2 is provided with a one-way valve 15. When the nasal plug has a gas supply, the one-way valve 15 is always closed under gas pressure or in a natural state. When the equipment fails, there is no gas supply. Pneumatic action, the one-way valve 15 opens and communicates with the atmosphere to supply air to the patient under a small inspiratory pressure to ensure the patient's aerobic respiration. The air source connection tube 2 is also provided with a test pressure connection port 16 for real-time The air pressure in the pipeline is monitored. The nasal plug head 1 is connected to the air source access tube 2. The air source access tube 2 is provided with a fixed structure for fitting and f...

Embodiment 3

[0034] like Figure 5As shown, a pressure-controllable respiratory nasal plug includes a nasal plug head 1 and an air source inlet pipe 2, the air source inlet pipe 2 is provided with an air source input port 3, and the number of the air source input port 3 is two. Two gas source input ports 3 are respectively located at the two ends of the gas source inlet pipe 2, and gas can be input through the two gas source inlet ports 3. The side wall of the gas source inlet pipe 2 is provided with a check valve 15. When under gas pressure, or in the natural state, the one-way valve 15 is always closed. When the equipment fails, there is no gas supply. As long as the patient has an inhalation action, the one-way valve 15 is opened under a very small inspiratory pressure to meet the atmosphere. Connected to supply air to the patient to ensure the patient's aerobic respiration. The air source connection pipe 2 is also provided with a test pressure connection port 16 for real-time monitorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com