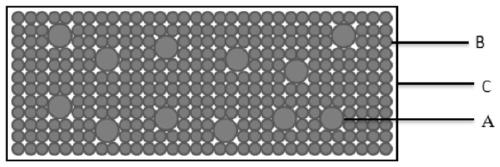

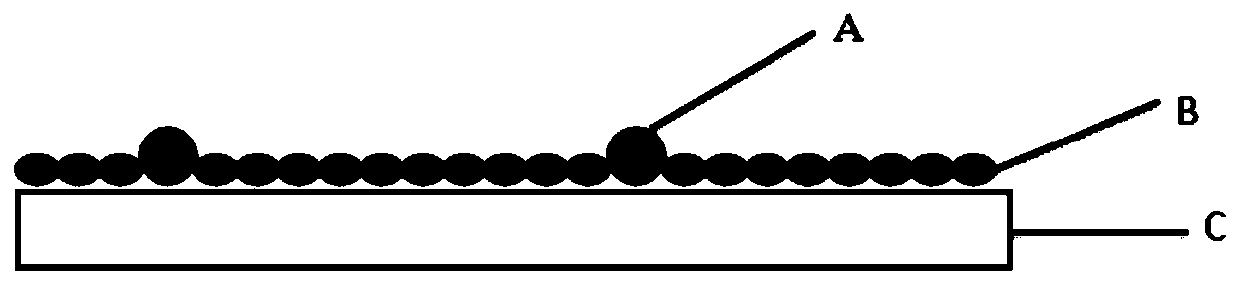

Lithium ion battery diaphragm and preparation method thereof

A lithium-ion battery and diaphragm technology, applied in the field of lithium-ion battery diaphragm and its preparation, can solve the problems of poor air permeability of products, low adhesion between coating and pole piece, low proportion of ceramics, etc., and achieve the accumulation of small molecules Weakening, the effect of good pole piece bonding performance and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

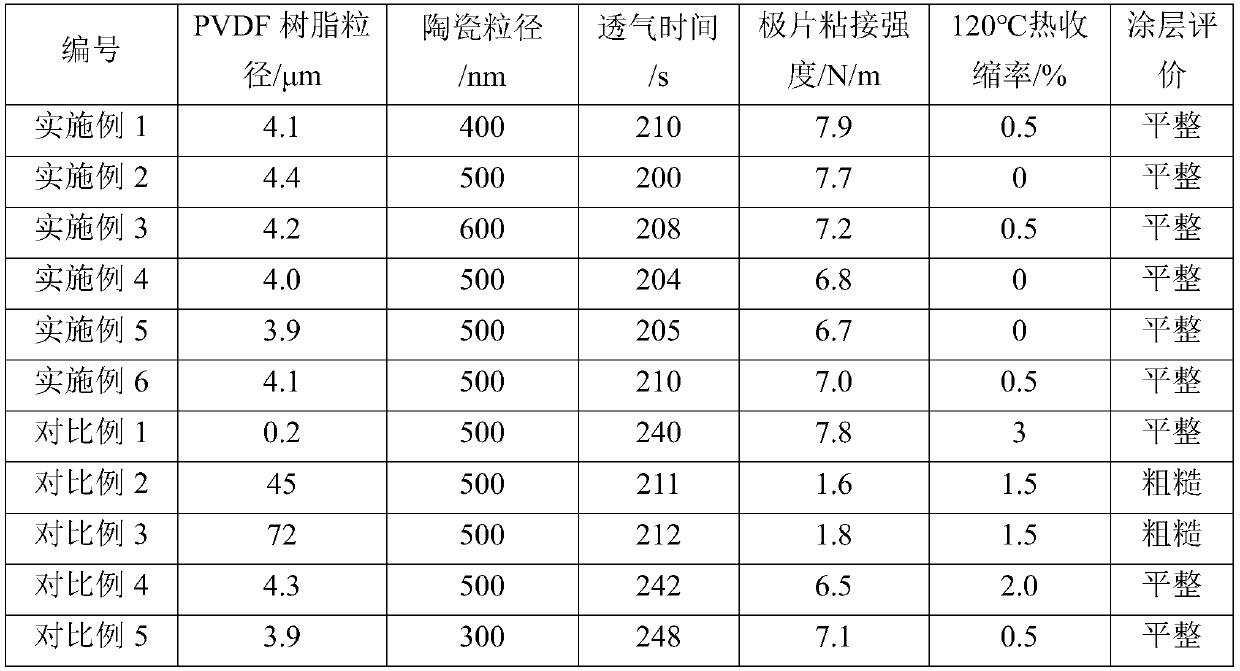

Examples

Embodiment 1

[0066] Preparation of PVDF copolymer resin suspension:

[0067] Add 100kg of deionized water and 0.1kg of polyvinyl alcohol dispersant to the reaction kettle, vacuumize and replace with nitrogen, so that the oxygen content in the kettle is lower than 30ppm. Start the mechanical stirring, control the stirring speed to 800r / min, and raise the temperature of the reaction kettle to 29°C. The VDF monomer and the HFP monomer are uniformly mixed and passed into the reactor, wherein HFP accounts for 1% of the total mass of the comonomers, and the internal pressure of the reactor is controlled to be 4.5 MPa. Add 0.001kg of diisopropyl peroxydicarbonate initiator and 0.04kg of diethyl malonate chain transfer agent to start the polymerization reaction. During the polymerization process, continuously replenish mixed monomers to keep the pressure in the kettle at 4.5MPa. When the cumulative reaction amount of the monomer is 20kg, the reaction is terminated, the reaction time is 7.2h, and ...

Embodiment 2

[0071] Preparation of PVDF copolymer resin suspension:

[0072] Add 100kg of deionized water and 0.4kg of methylcellulose dispersant to the reaction kettle, vacuumize and replace with nitrogen, so that the oxygen content in the kettle is lower than 30ppm. Start the mechanical stirring, control the stirring speed to 1000r / min, and raise the temperature of the reaction kettle to 27°C. The VDF monomer and the HFP monomer are uniformly mixed and passed into the reactor, wherein HFP accounts for 5% of the total mass of the comonomers, and the pressure inside the reactor is controlled to be 5.0 MPa. Add 0.002 kg of tert-butyl peroxyisobutyrate initiator and 0.02 kg of butyl acetate chain transfer agent, and the polymerization reaction starts. During the polymerization process, the mixed monomers are constantly replenished to keep the pressure in the kettle at 5.0 MPa. When the cumulative monomer reaction amount is 20kg, the reaction is terminated, the reaction time is 6.3h, and the...

Embodiment 3

[0076] Preparation of PVDF copolymer resin suspension:

[0077] Add 100kg of deionized water and 0.6kg of hydroxymethyl cellulose dispersant to the reaction kettle, vacuumize and replace with nitrogen, so that the oxygen content in the kettle is lower than 30ppm. Start the mechanical stirring, control the stirring speed to 1500r / min, and raise the temperature of the reaction kettle to 29°C. The VDF monomer and the HFP monomer are uniformly mixed and passed into the reactor, wherein HFP accounts for 10% of the total mass of the comonomers, and the pressure inside the reactor is controlled to be 5.5 MPa. Add 0.02 kg of di-tert-butyl peroxide initiator and 0.16 kg of butyl diacetate chain transfer agent to start the polymerization reaction. During the polymerization process, the mixed monomers are continuously replenished to keep the pressure in the kettle at 5.5 MPa. When the cumulative monomer reaction amount is 20kg, the reaction is terminated, the reaction time is 3.6h, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com