Driving method of electronic ink for display

A technology of electronic ink and driving method, applied in static indicators, instruments, etc., can solve the problems of instability, reduction of electrowetting aperture ratio, influence of display effect, etc., to improve the degree of shrinkage, realize aperture ratio, and overcome easy dispersion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

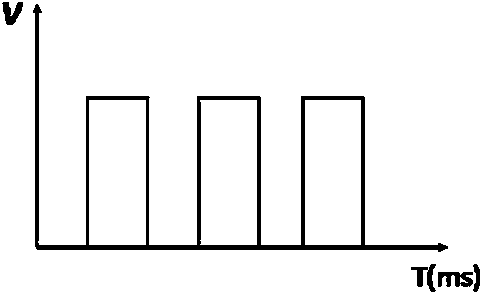

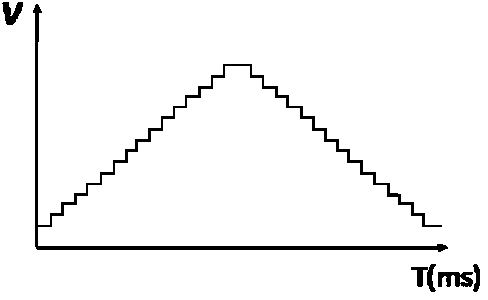

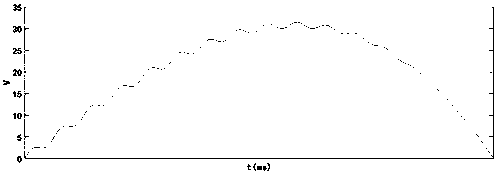

[0023] refer to image 3 , a driving method of electronic ink for display, including calculating the electrowetting ink driving voltage U of the electrowetting original, after editing the driving voltage U of the electrowetting ink with an editable function generator, the voltage is obtained through a high-voltage amplifier Wetting the ink driving voltage waveform, loading the electrowetting ink driving voltage waveform output by the high voltage amplifier to the input port of the electrowetting display.

[0024] The driving voltage U of the electrowetting ink is:

[0025] U=10 -4 x 2 +1(sin(x)+bx).

[0026] Where b is an arbitrary constant, and generally b takes 0 or 1.

[0027] The calculation and loading of the electrowetting ink drive U is an existing technology, and a computer with readable memory can be used to perform the calculation, and a common voltage loader can be used to load the output voltage of the high-voltage amplifier.

[0028] The driving voltage U of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com