Quick-repair wash-free dual-valve-element shut-off valve convenient to replace

A shut-off valve and quick-repair technology, which is applied in the field of quick-repair flush-free double-core globe valves, can solve the problems of increasing repair, maintenance and procurement costs, wasting system energy, and economic losses, so as to improve social and economic benefits and reduce Procurement cost, effect of extending service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

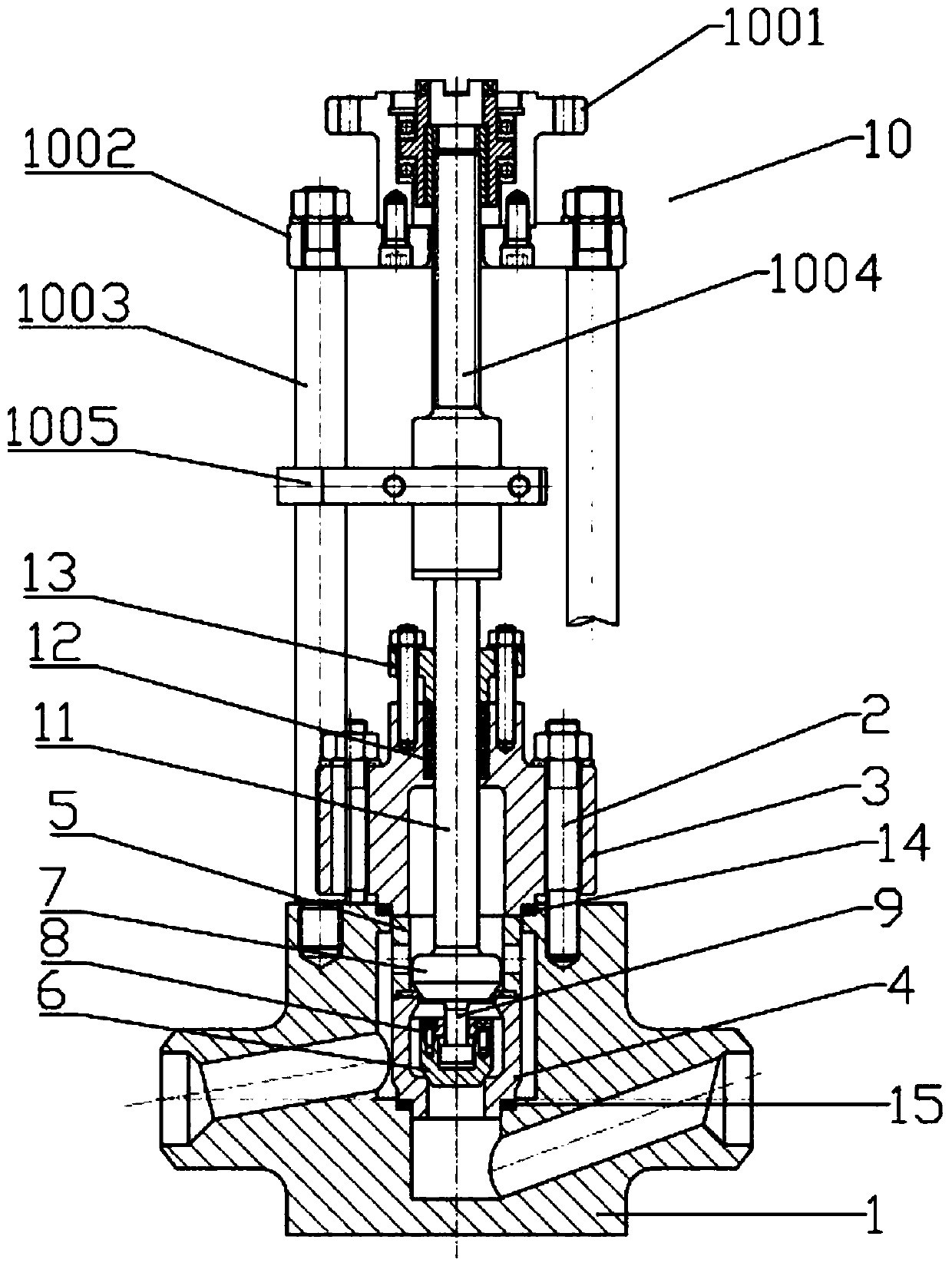

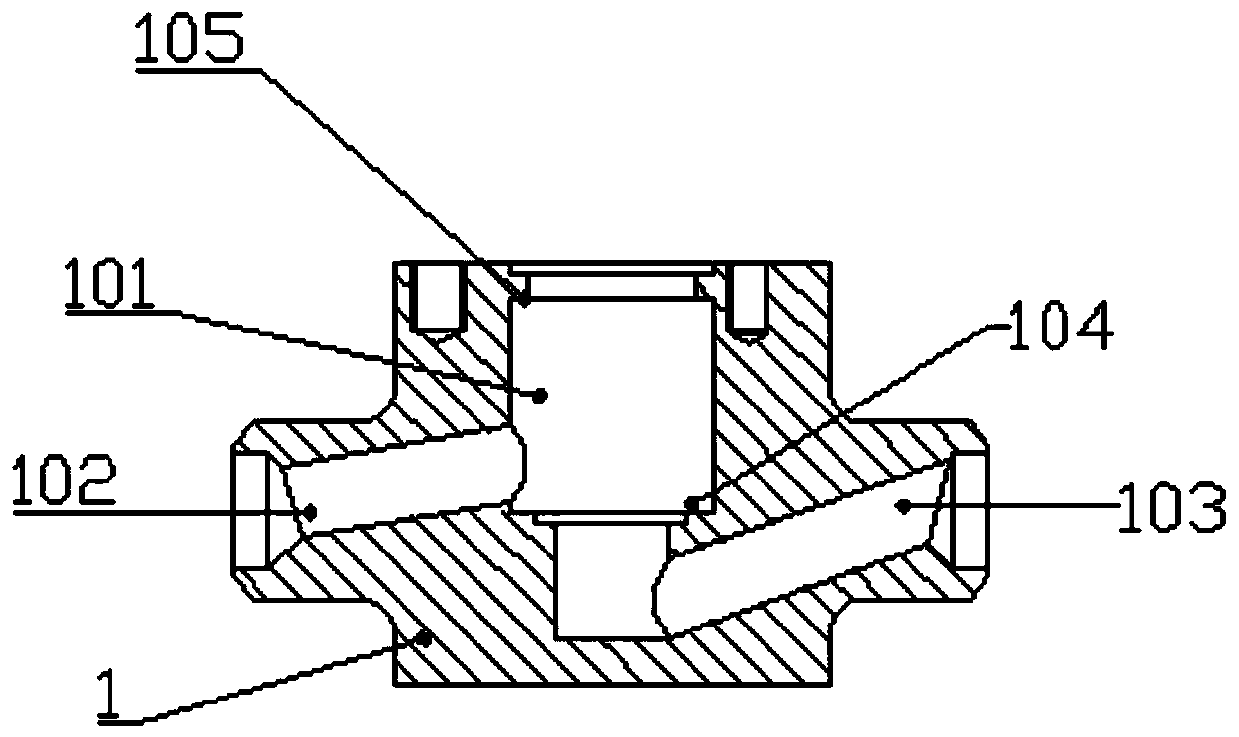

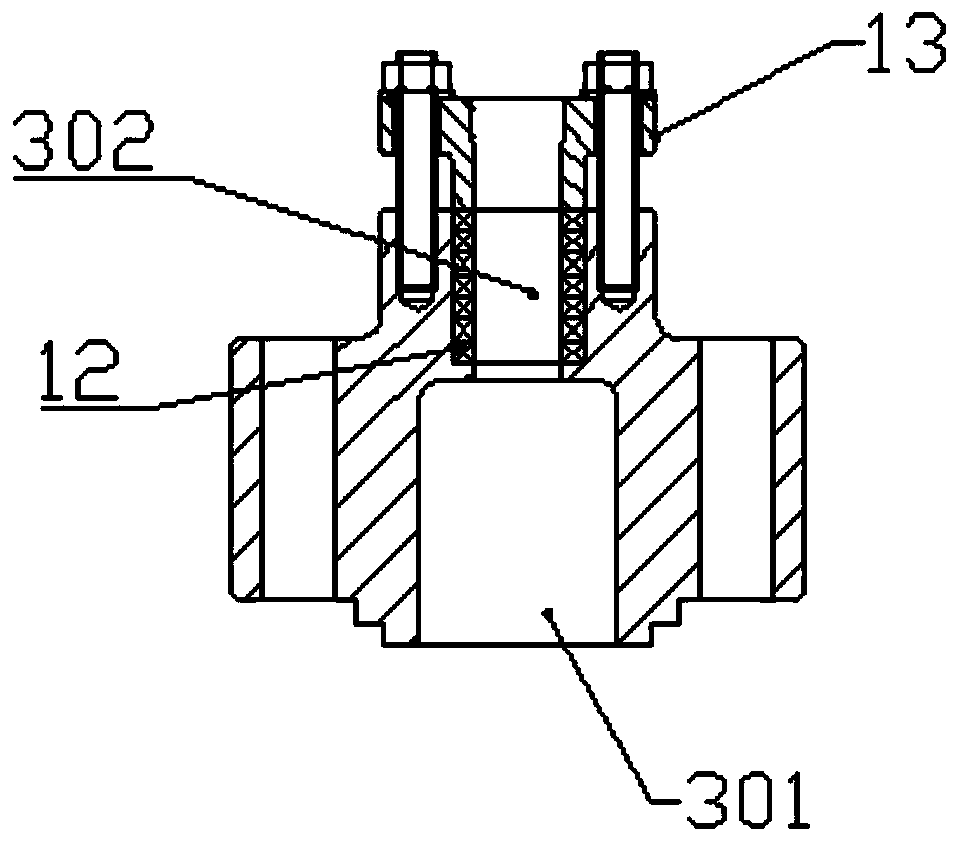

[0026] Such as Figure 1-7 In the shown embodiment, a quick-repair flush-free double-core globe valve that is easy to replace includes a valve body 1 and a valve cover 3 installed on the upper end of the valve body 1 through bolts 2. The valve body 1 includes a water chamber 101, a fluid inlet Channel 102 and fluid outlet channel 103, the upper part of the water chamber 101 of the valve body 1 is wide, the middle and lower part is narrow, and the middle part is provided with a transition card groove 104. It is inclined upwards and communicates with the middle and upper part of the water chamber 101. The fluid outlet channel 103 is inclined from the bottom upwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com