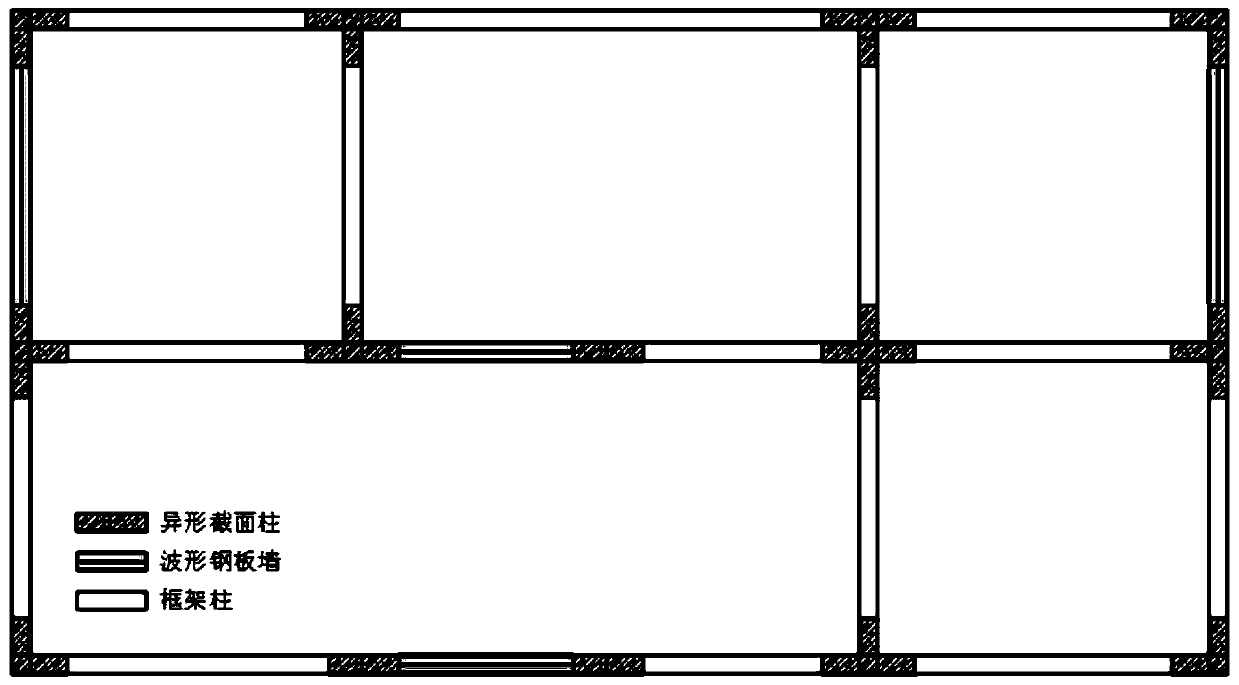

Structure system composed of special-shaped cross section column frame and corrugated sheet steel wall

A technology of special-shaped cross-section columns and corrugated steel plates, which is applied to walls, building components, building structures, etc., can solve the problems of limited bearing capacity of corrugated steel plate shear walls and hinder the application of corrugated steel plate shear wall systems, and achieve energy dissipation Excellent shock absorption characteristics, improvement of insufficient bearing capacity, and effect of increased buckling load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] combined with figure 1 ~7, describe the specific embodiment of the present invention in detail. A special-shaped cross-section column frame-corrugated steel plate wall structure system includes the following parts:

[0045] 1—corrugated steel plate wall, of which: 1-1—single corrugated steel plate; 1-2—stiffened corrugated steel plate wall; 1-3—double corrugated steel plate wall connected by parallel hooks; 1-4—orthogonal Double corrugated steel plate wall with buckle connection;

[0046] 2——Special-shaped cross-section column (indicated by L-shaped cross-section);

[0047] 3 - frame beam;

[0048] 4 - Pull bolts;

[0049] 5 - weld;

[0050] 6——T-shaped connectors, of which: 6-1—corrugated steel plate connecting plate; 6-2—frame beam-column connecting plate; 6-3—long round hole high-strength bolt; 6-4—stiffening rib.

[0051] 7——stiffener

[0052] 8——Wave form of corrugated steel plate, among which: 8-1——Corrugated steel plate in trapezoidal corrugated form; 8-2—...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com