Catalyst carrier and catalyst for synthesizing dimethyl oxalate

A technology of dimethyl oxalate and catalyst carrier, which is applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., and can solve the problem of poor catalyst activity and the combination of carriers and additives Poor strength and other problems, to achieve long service life, improve activity and stability, and enhance the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

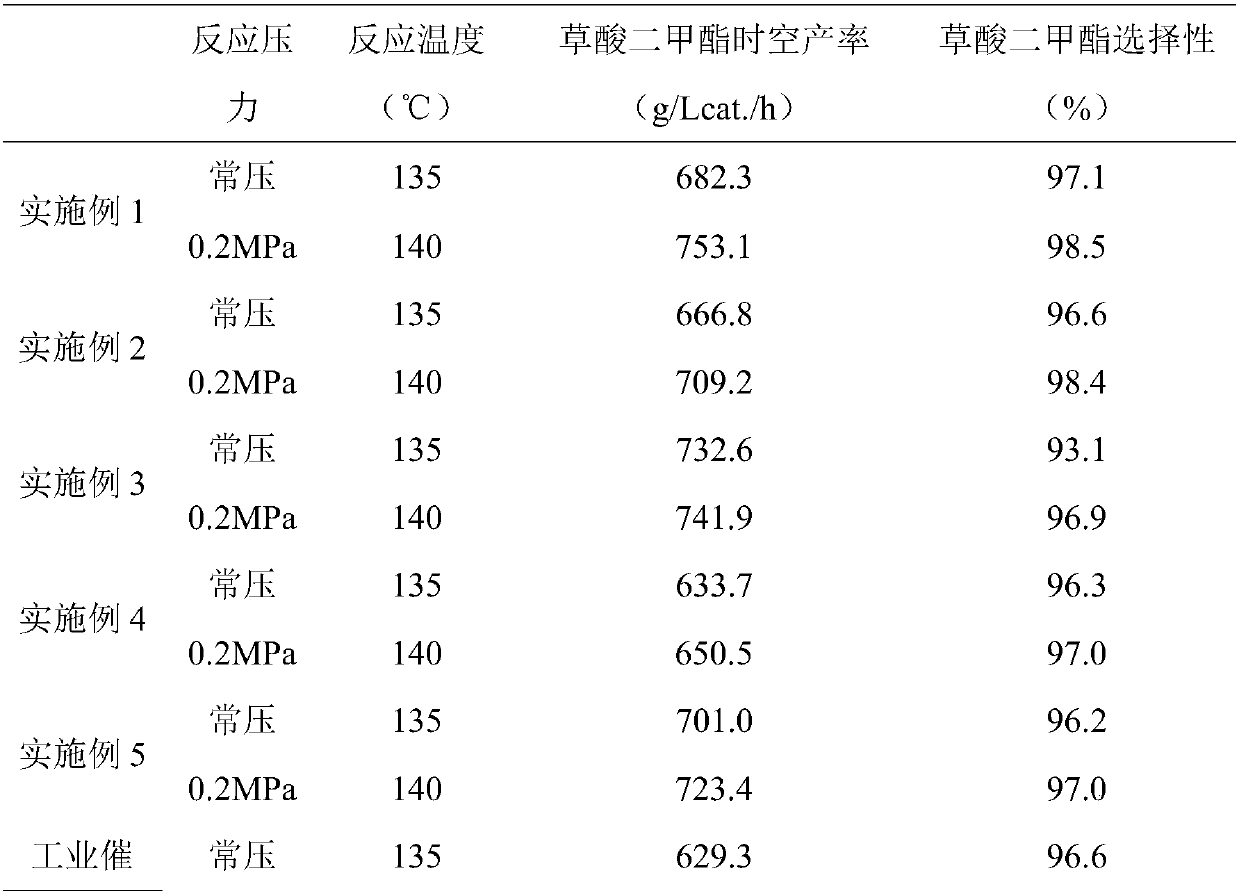

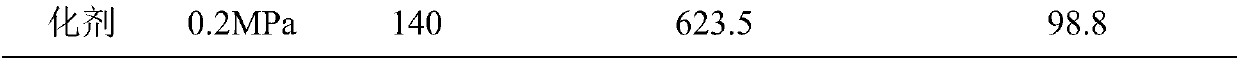

Examples

Embodiment 1

[0036] The embodiment 1 of the catalyst that is used for the synthesis of dimethyl oxalate of the present invention adopts the following steps to prepare:

[0037] 1) 153g Al(OH) 3 Disperse in 300g deionized water to form a suspension, which is recorded as liquid A;

[0038] Weigh 52g of NaOH and dissolve it in 100g of deionized water, and record it as liquid B;

[0039] Weigh 47.6g of concentrated hydrochloric acid and drop it into 100g of deionized water, and record it as liquid C;

[0040] Weigh 0.76g Cu(NO 3 ) 2 ·3H 2 O, denoted as D;

[0041] 8g NaOH and 15.6g Al(OH) 3 Dissolve in 100g deionized water to form NaAlO 2 Solution, denoted as E solution;

[0042] Weigh 0.28g PdCl 2 Dissolve in 43g of water, drop into liquid C, make the pH of the solution between 4-6, and record it as liquid F;

[0043] Gradually drop liquid B into liquid A, stir for 2 hours, then drop a certain amount of liquid C to adjust the pH of the system to 7.5-8.5, continue stirring for 2 hours,...

Embodiment 2

[0049] The embodiment 2 of the catalyst that is used for the synthesis of dimethyl oxalate of the present invention adopts the following steps to prepare:

[0050] 1) 153g Al(OH) 3 Disperse in 300g deionized water to form a suspension, which is recorded as liquid A;

[0051] Weigh 52g of NaOH and dissolve it in 100g of deionized water, and record it as liquid B;

[0052] Weigh 47.6g of concentrated hydrochloric acid and drop it into 100g of deionized water, and record it as liquid C;

[0053] Weigh 0.91g Ni(NO 3 ) 2 ·6H 2 O, denoted as D;

[0054] 8g NaOH and 15.6g Al(OH) 3 Dissolve in 100g deionized water to form NaAlO 2 Solution, denoted as E solution;

[0055] Weigh 0.28g PdCl 2 Dissolve in 43g of water, drop into liquid C, make the pH of the solution between 4-6, and record it as liquid F;

[0056] Gradually drop liquid B into liquid A, stir for 1 h, then drop a certain amount of liquid C to adjust the pH of the system to 8.0-9.0, continue stirring for 1 h, and t...

Embodiment 3

[0062] The embodiment 3 of the catalyst that is used for the synthesis of dimethyl oxalate of the present invention adopts the following steps to prepare:

[0063] 1) 153g Al(OH) 3 Disperse in 300g deionized water to form a suspension, which is recorded as liquid A;

[0064] Weigh 52g of NaOH and dissolve it in 100g of deionized water, and record it as liquid B;

[0065] Weigh 47.6g of concentrated hydrochloric acid and drop it into 100g of deionized water, and record it as liquid C;

[0066] Weigh 0.93g Zn(NO 3 ) 2 ·6H 2 O, denoted as D;

[0067] 8g NaOH and 15.6g Al(OH) 3 Dissolve in 100g deionized water to form NaAlO 2 Solution, denoted as E solution;

[0068] Weigh 0.28g PdCl 2 Dissolve in 43g of water, drop into liquid C, make the pH of the solution between 4-6, and record it as liquid F;

[0069] Gradually drop liquid B into liquid A, stir for 4 hours, then drop a certain amount of liquid C to adjust the pH of the system to 7.5-9.0, continue stirring for 4 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com