a kind of ceo x Preparation method and application of /mc nanosheet material

A technology of nanosheets and raw materials, applied in the direction of fuel cell half-cells and secondary battery-type half-cells, structural parts, electrical components, etc., to achieve the effects of easy scale production, abundant raw material sources, and large load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Remove the hard shell from the corn stalks recovered from the farm, break them into small particles, place them in 1.5wt.% sulfuric acid solution at 70°C and stir for 3 hours, wash with deionized water until neutral, and filter the obtained product Dry at 35°C to obtain biomass carbon raw material.

[0043] (2) Weigh cerium acetate and dissolve it in deionized water, and stir to completely dissolve it to obtain a 50 mM solution.

[0044] (3) Place the biomass carbon raw material in step (1) in the solution configured in step (2) for immersion, ultrasonic treatment for 20 minutes, vacuum treatment for 20 minutes, ultrasonic treatment for 20 minutes again, filter, and filter the obtained product Fully dry, the drying temperature is 35°C.

[0045] (4) The product dried in step (3) was calcined at 600°C for 4 hours in an argon atmosphere, and the heating rate was 5°C / min to obtain CeO x / MC nanosheet material.

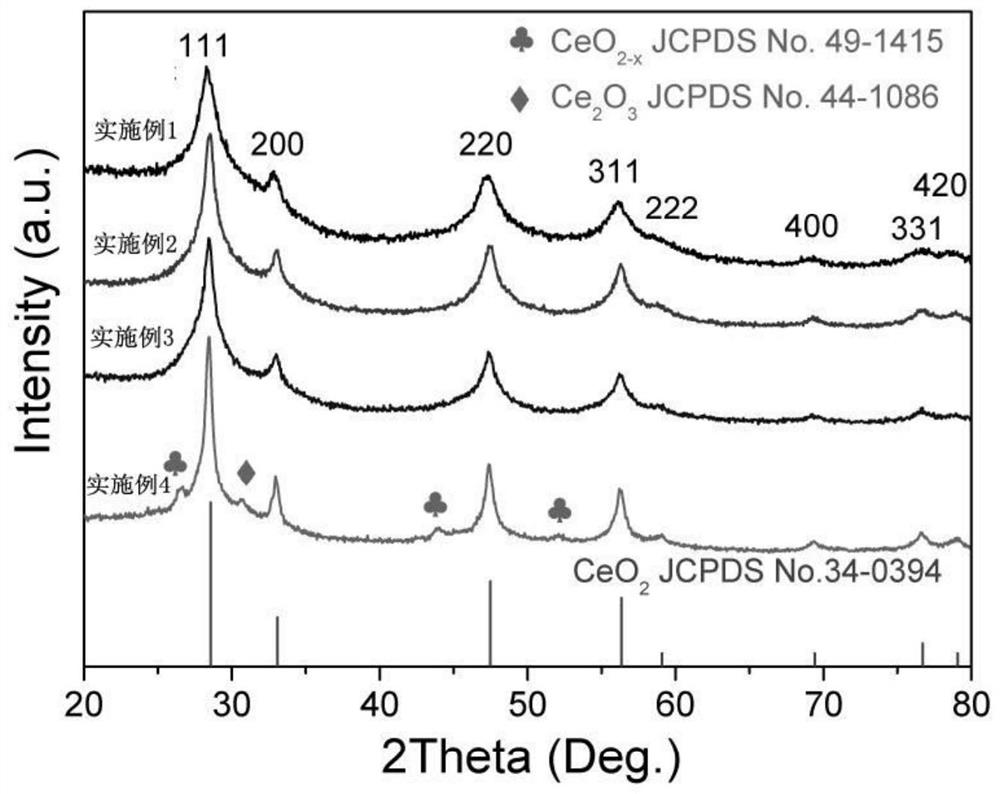

[0046] attached figure 1 The first curve above is the Ce...

Embodiment 2

[0048] (1) Remove the hard shell from the corn stalks recovered from the farm, break them into small particles, place them in 2wt.% hydrochloric acid solution at 85°C and stir for 2 hours, wash with deionized water until neutral, and place the filtered product in Dry at 45°C to obtain biomass carbon raw material.

[0049] (2) Weigh cerium chloride and dissolve it in deionized water, and stir to completely dissolve it to obtain a 30 mM solution.

[0050] (3) Place the biomass carbon raw material in step (1) in the solution configured in step (2) to immerse, sonicate for 30 minutes, vacuum treat for 30 minutes, sonicate for 30 minutes again, filter, and filter the obtained product Fully dry, the drying temperature is 45 ℃.

[0051] (4) The product dried in step (3) was calcined in an argon atmosphere at 700°C for 5 hours at a heating rate of 5°C / min to obtain CeO x / MC nanosheet material.

[0052] attached figure 1 The second curve above is the CeO prepared in Example 2 x / ...

Embodiment 3

[0054] (1) Remove the hard shell from the corn stalk recovered from the farm, break it into small particles, place it in a 5wt.% sulfuric acid solution and stir it at 95°C for 1 hour, wash it with deionized water until it is neutral, and place the filtered product Dry at 50°C to obtain biomass carbon raw material.

[0055] (2) Weigh cerium nitrate and dissolve it in deionized water, stir to make it dissolve completely to obtain a 10 mM solution.

[0056] (3) Place the biomass carbon raw material in step (1) in the solution configured in step (2) for immersion, ultrasonic treatment for 45 minutes, vacuum treatment for 45 minutes, and sub-ultrasonic treatment for 45 minutes, and filter. The product was fully dried, and the drying temperature was 60°C.

[0057] (4) The product dried in step (3) was calcined at 800°C for 4 hours in an argon atmosphere, and the heating rate was 10°C / min to obtain CeO x / MC nanosheet material.

[0058] attached figure 1 The third curve above is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com