Arc welding seam forming accurate prediction method based on deep learning

An arc welding seam and deep learning technology, applied in neural learning methods, biological neural network models, geometric CAD, etc., can solve problems such as ineffective mathematical modeling methods, difficult applications, and inefficient analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above objects, features and advantages of the present invention more clearly understood, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

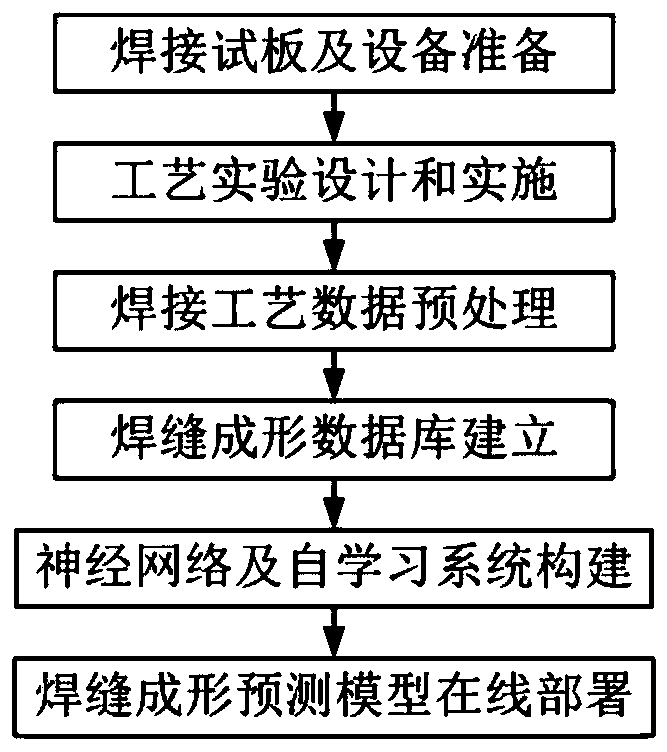

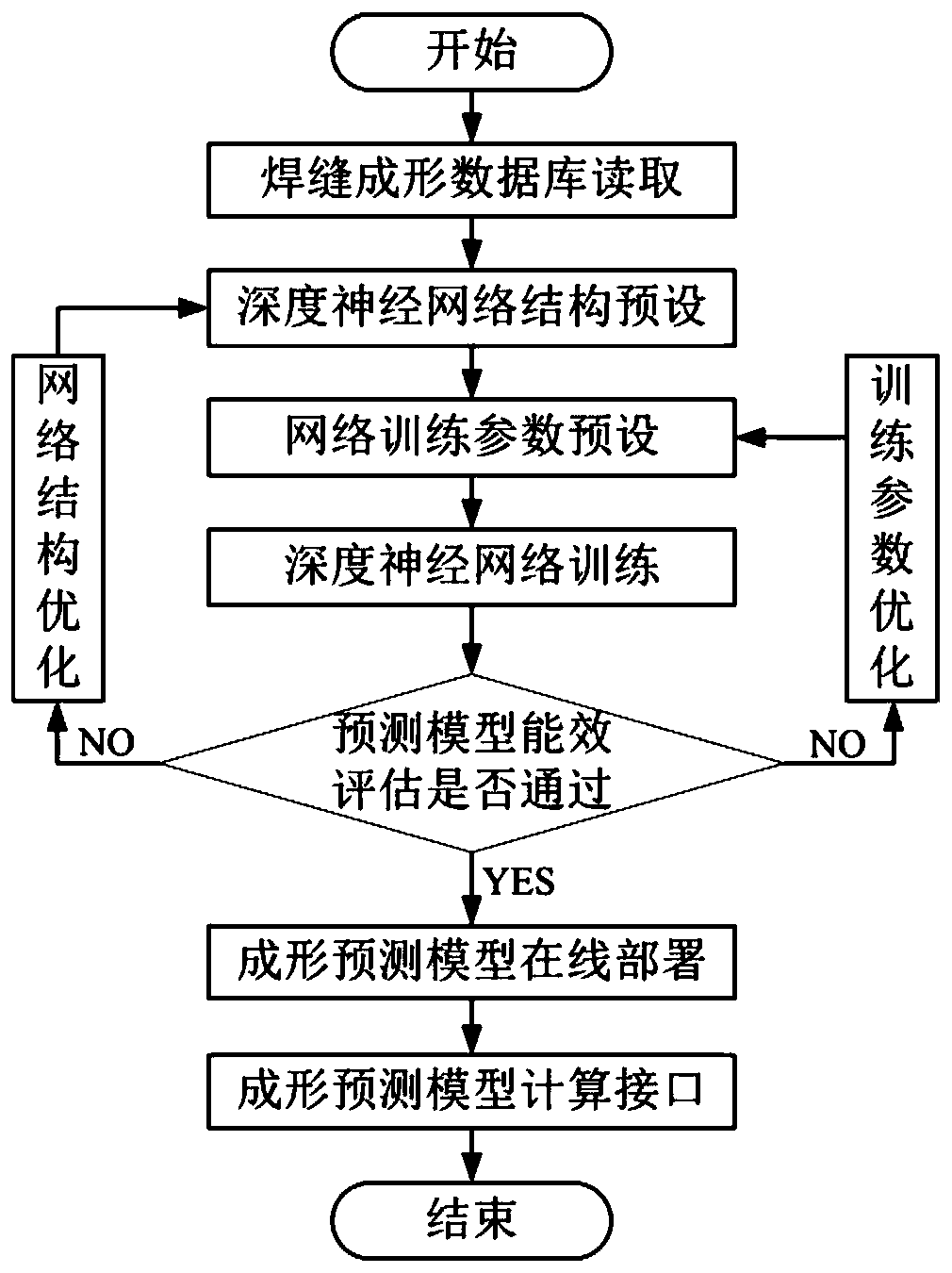

[0032] The invention discloses an accurate prediction method for arc welding seam forming based on deep learning, comprising:

[0033] Design the corresponding welding process according to the welding equipment, welding materials, structural forms and welding methods;

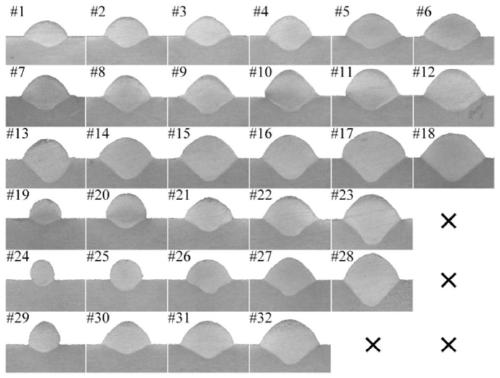

[0034] Design corresponding process experiments according to the welding process, and implement them in batches to obtain process test data; the process test data include welding equipment model, material grade, structural form, welding method, process parameters, welding seam forming size and welding seam section profile;

[0035] Weld forming sub-databases are established according to different combinations of welding equipment models, material grades, structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com