High-temperature garbage incineration grate furnace system based on material circulation and working method

A waste incinerator and material recycling technology, applied in the direction of combustion method, incinerator, combustion type, etc., to achieve the effect of long residence time, reducing blockage, improving efficiency and distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

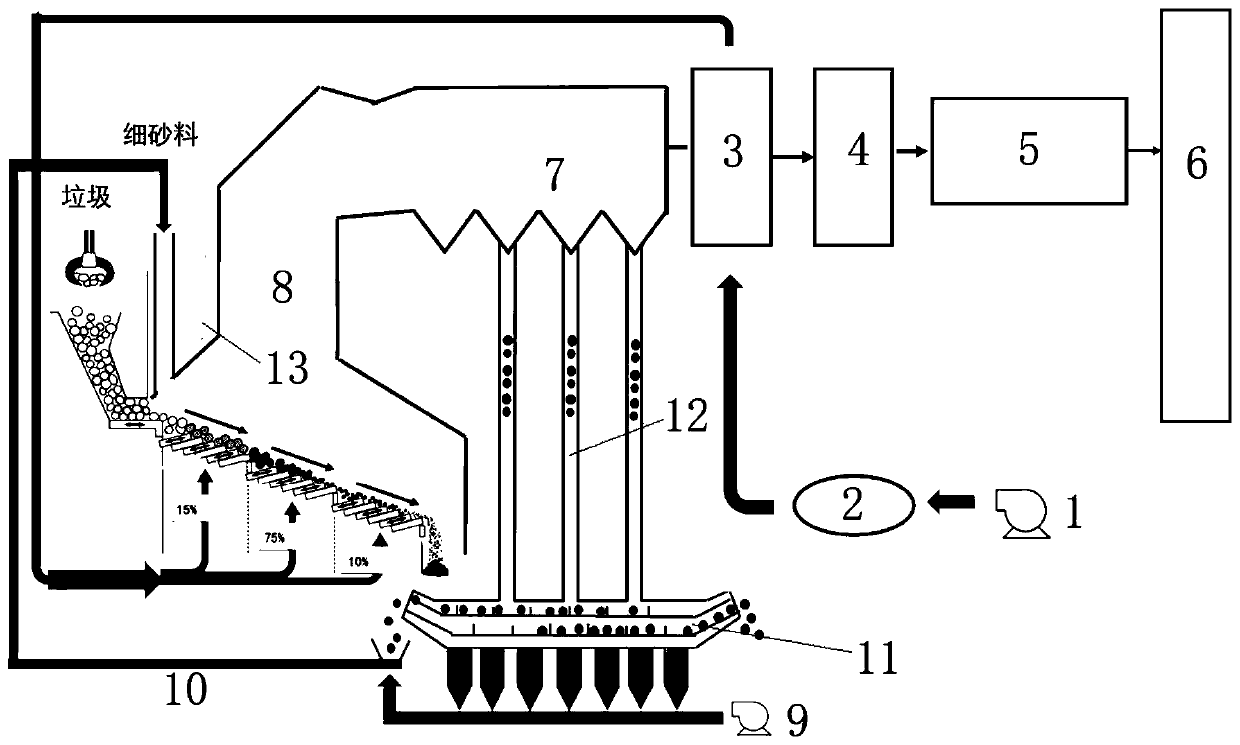

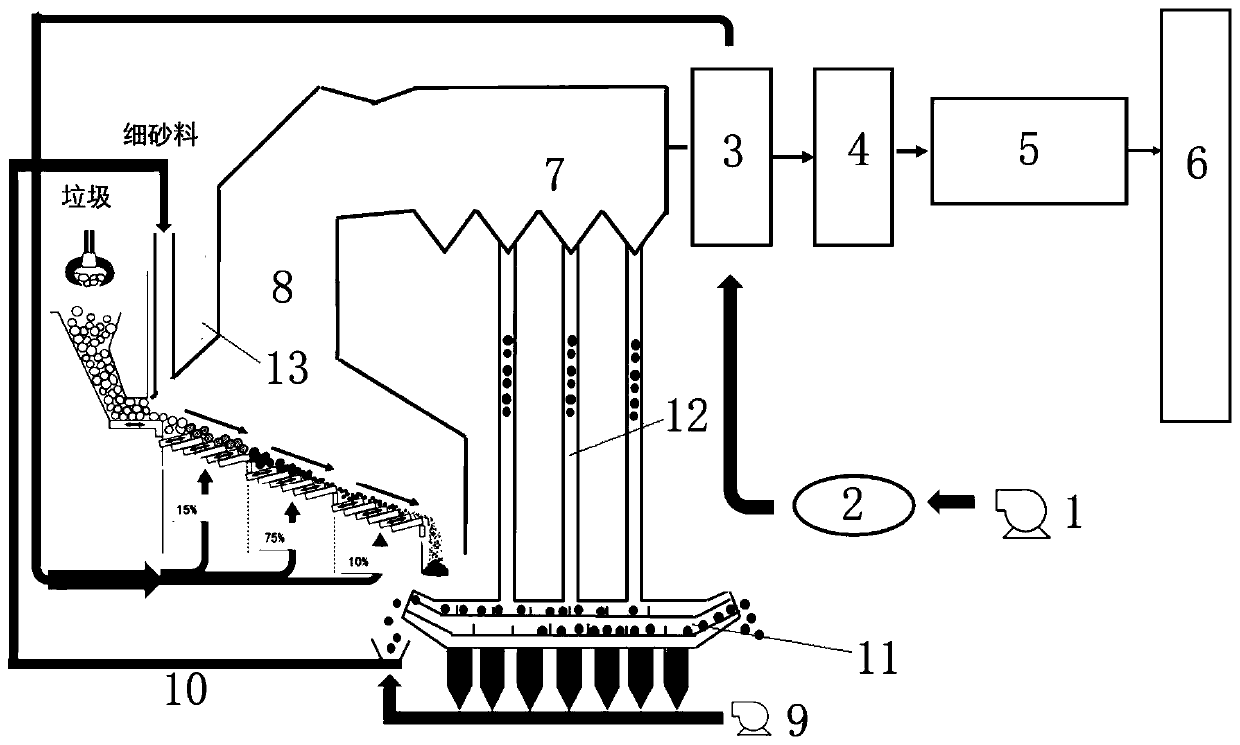

[0036] A high-temperature waste incineration grate furnace system based on material circulation of the present invention, such as figure 1 , including grate furnace, primary fan 1, primary air steam preheater 2, air preheater 3, economizer 4, flue gas treatment system 5, chimney 6, conveying fluidization fan 9 and sorting machine 11;

[0037] The primary fan 1 is connected to the primary air steam preheater 2, the primary air steam preheater 2 is connected to the air inlet of the air preheater 3, and the air outlet of the air preheater 3 is connected to the primary air inlet of the grate furnace; The hearth 8 of the grate is provided with a sand material inlet 13, and the sand material inlet 13 can be arranged above the grate drying section. The tail heating su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com