Integral aluminum die body based on narrow expansion joint

An expansion joint and integral technology, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, connectors of formwork/formwork/work frame, etc. On-site construction efficiency and other issues, to achieve the effect of guaranteed molding quality, easy support and dismantling construction, and easy partial replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

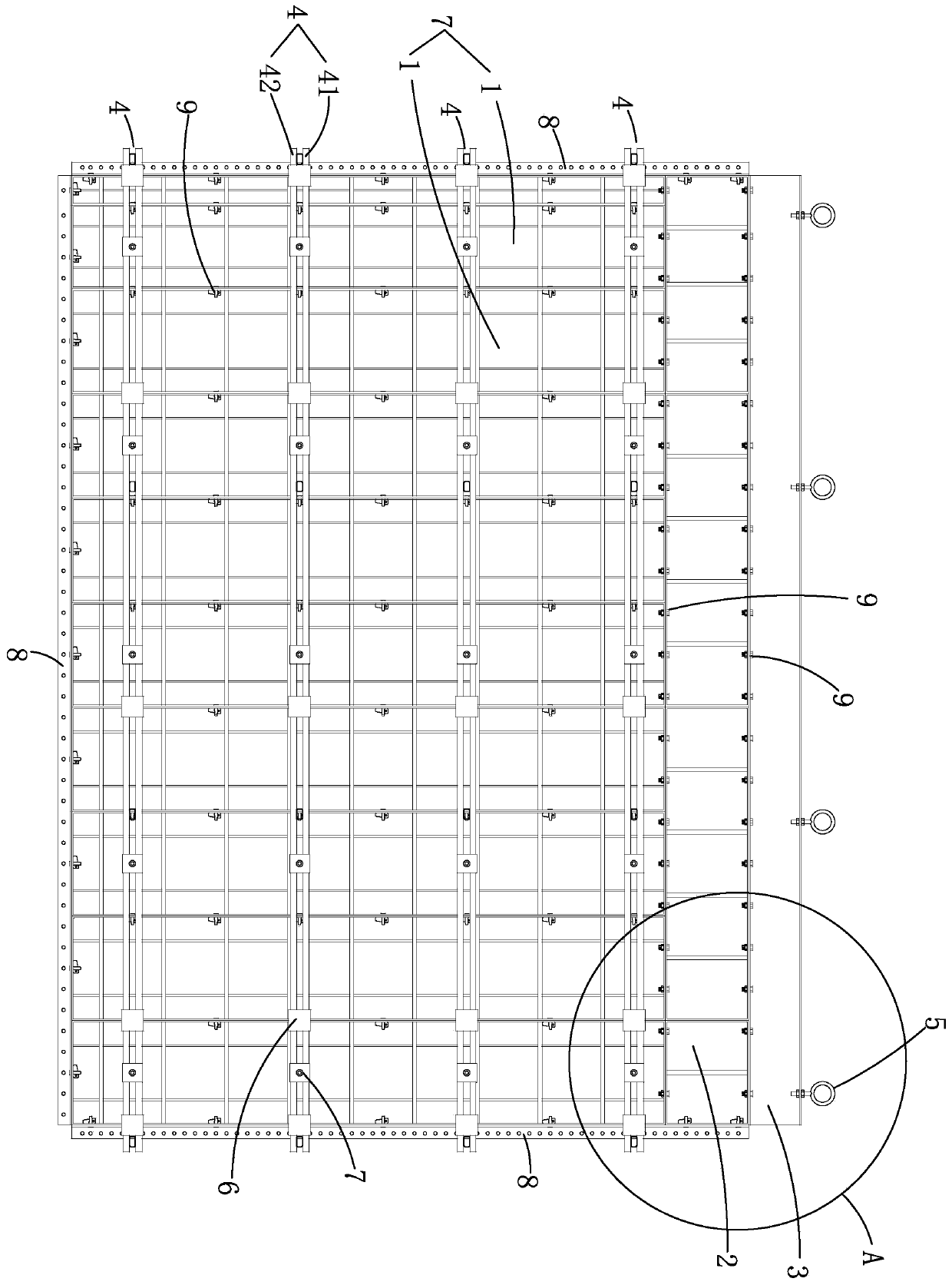

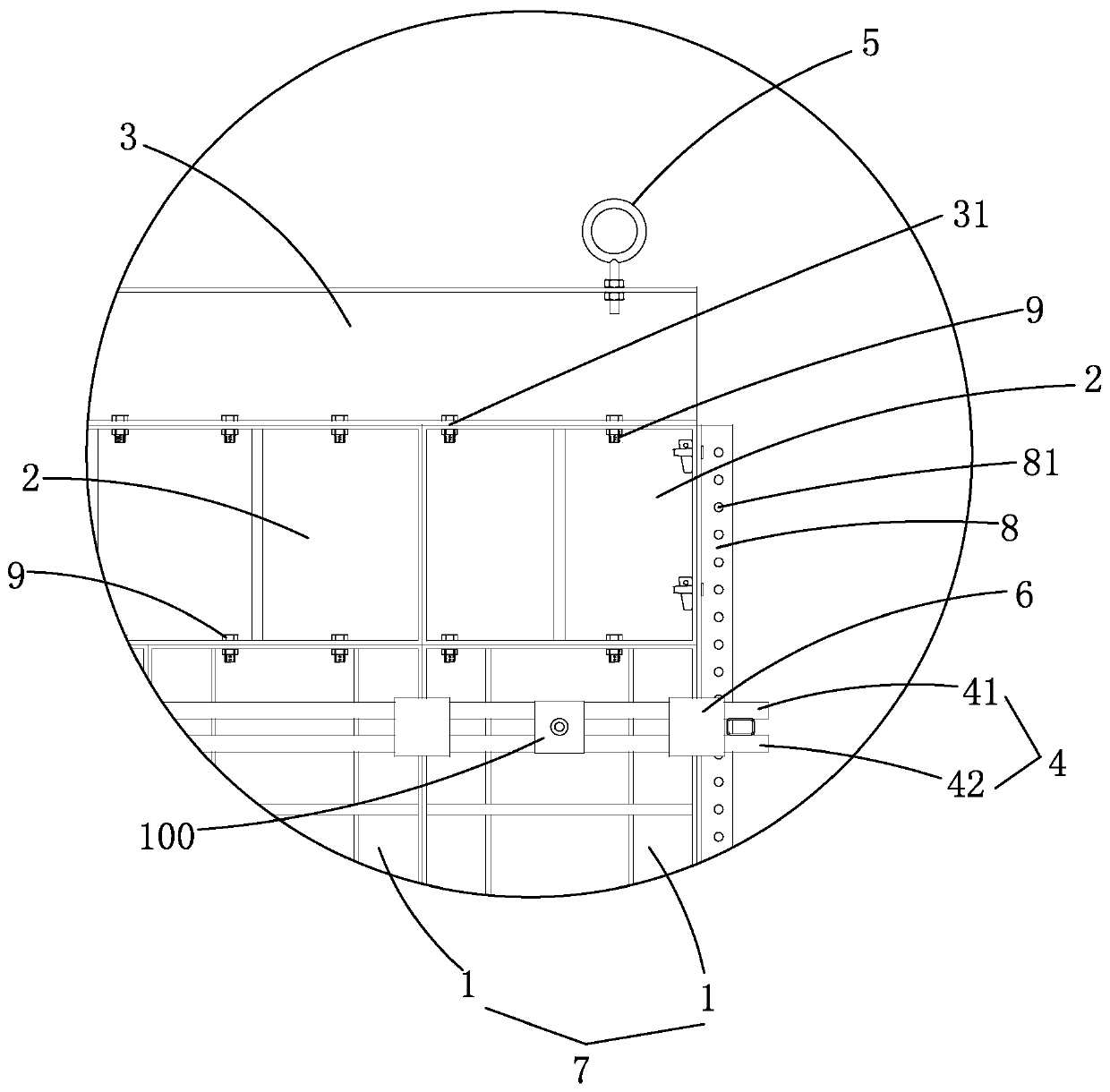

[0022] Example, combined with Figure 1 to Figure 3 As shown, an integral aluminum formwork body based on narrow expansion joints includes an aluminum formwork 1 , a K plate 2 , a profile steel 3 , a back flute 4 , a lifting ring 5 , a back flute buckle 6 and a tension screw 100 .

[0023] The aluminum formwork 1 is arranged according to the drawing size, the aluminum formwork 1 and the aluminum formwork 1 are connected, and the aluminum formwork 1 and the aluminum formwork 1 are locked by pins 9 to form a wallboard 7 .

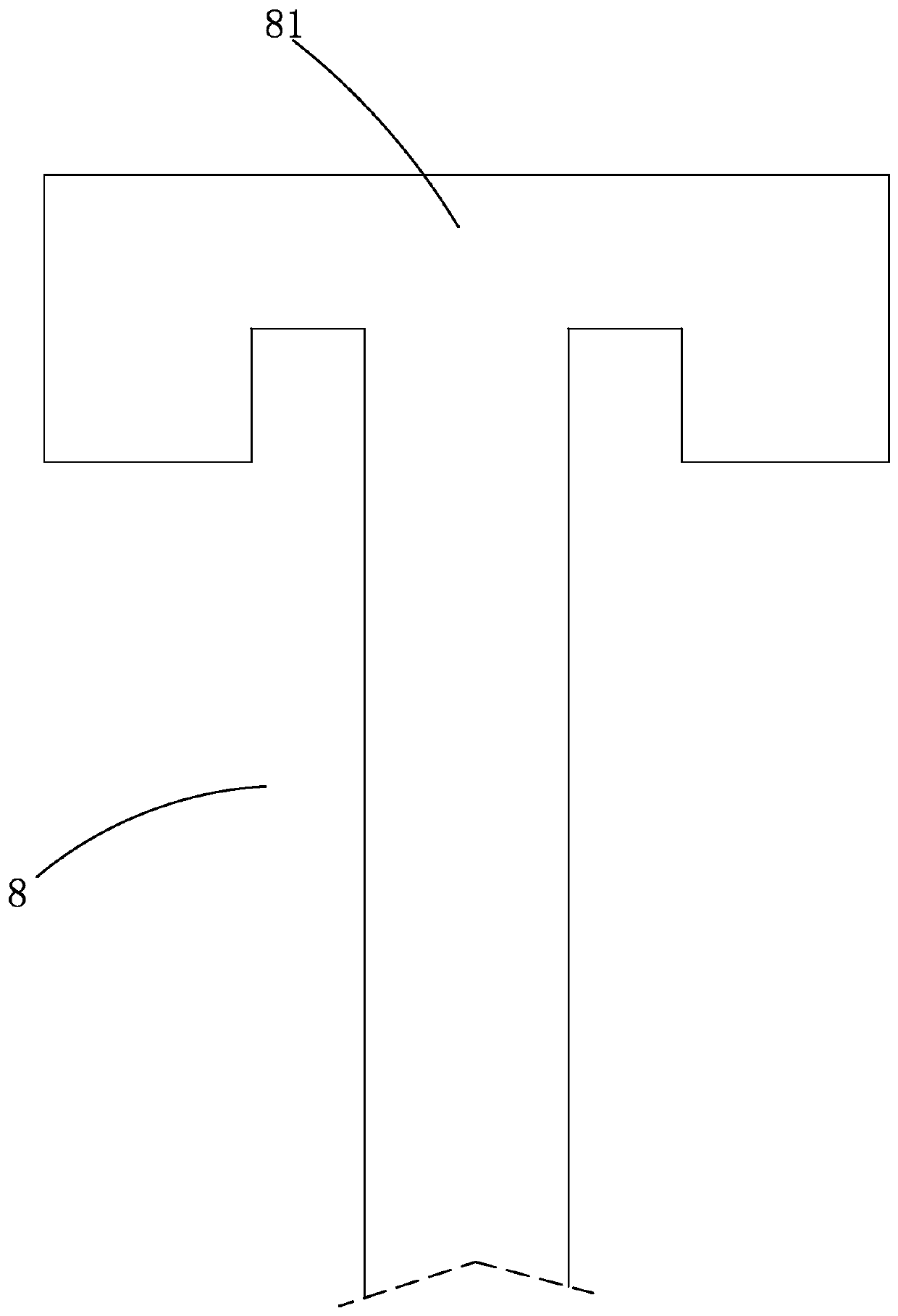

[0024] The left side, the bottom and the right side of the wallboard 7 are all provided with angled aluminum 8 , and the angled aluminum 8 is spaced with bolt holes 81 along its length direction.

[0025] The K board 2 is arranged on the top of the wall board 7 and connected to the wall board 7 , and the K board 2 and the aluminum formwork 1 are locked by pins 9 .

[0026] The shaped steel 3 is channel steel, the shaped steel 3 is arranged above the K plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com