Multifunctional active composite seal coat pavement

A composite sealing layer and multi-functional technology, which is applied to cohesive pavement paved on site, roads, roads, etc., can solve the problems of high cost, poor environmental protection, difficult construction, etc., and achieve the effect of resisting reflection cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

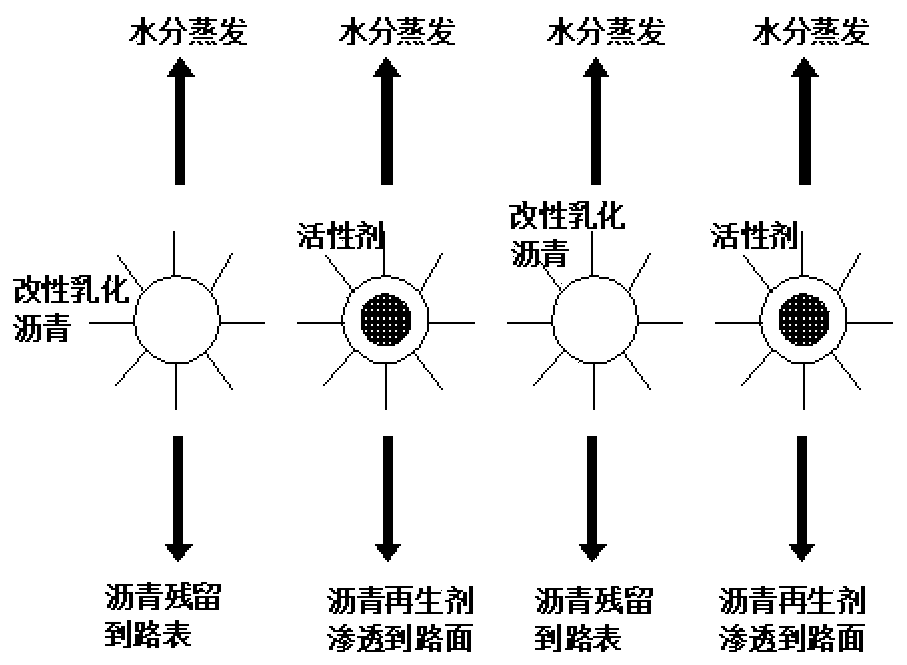

[0038] The preparation process of active emulsified asphalt is:

[0039] 1) Prepare modified emulsified asphalt;

[0040] Add asphalt emulsifier into water at 40°C-70°C, adjust the pH value to 1.5-2.5 with hydrochloric acid, and stir evenly, then add modifier and stabilizer to obtain emulsifier aqueous solution, and then heat the base or modified asphalt to 110°C-155°C, then add it into the colloid mill together with the emulsifier aqueous solution, and emulsify for 1min-2min to obtain modified emulsified asphalt;

[0041] 2) Active agent preparation process;

[0042] Mix the aged asphalt repair agent and repair aid, and then stir at 50°C-60°C for 20min-30min, and rise to the test temperature within 10min to obtain the aged asphalt repair emulsifier, and then dissolve the aged asphalt repair emulsifier in In hot water, get an aqueous solution, stir evenly, let it cool down to the test temperature within 5 minutes, then place the aqueous solution in a water bath at 50°C-80°C ...

Embodiment 1

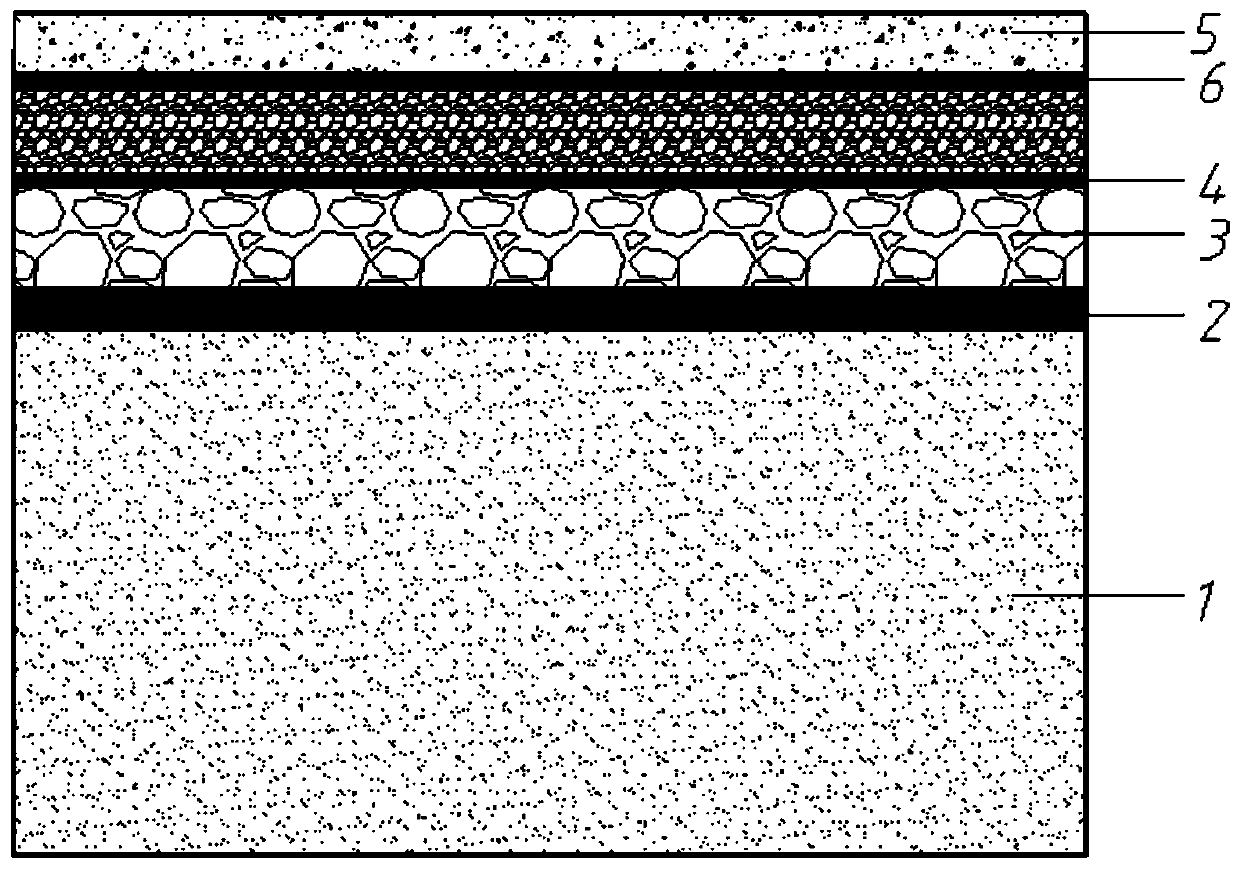

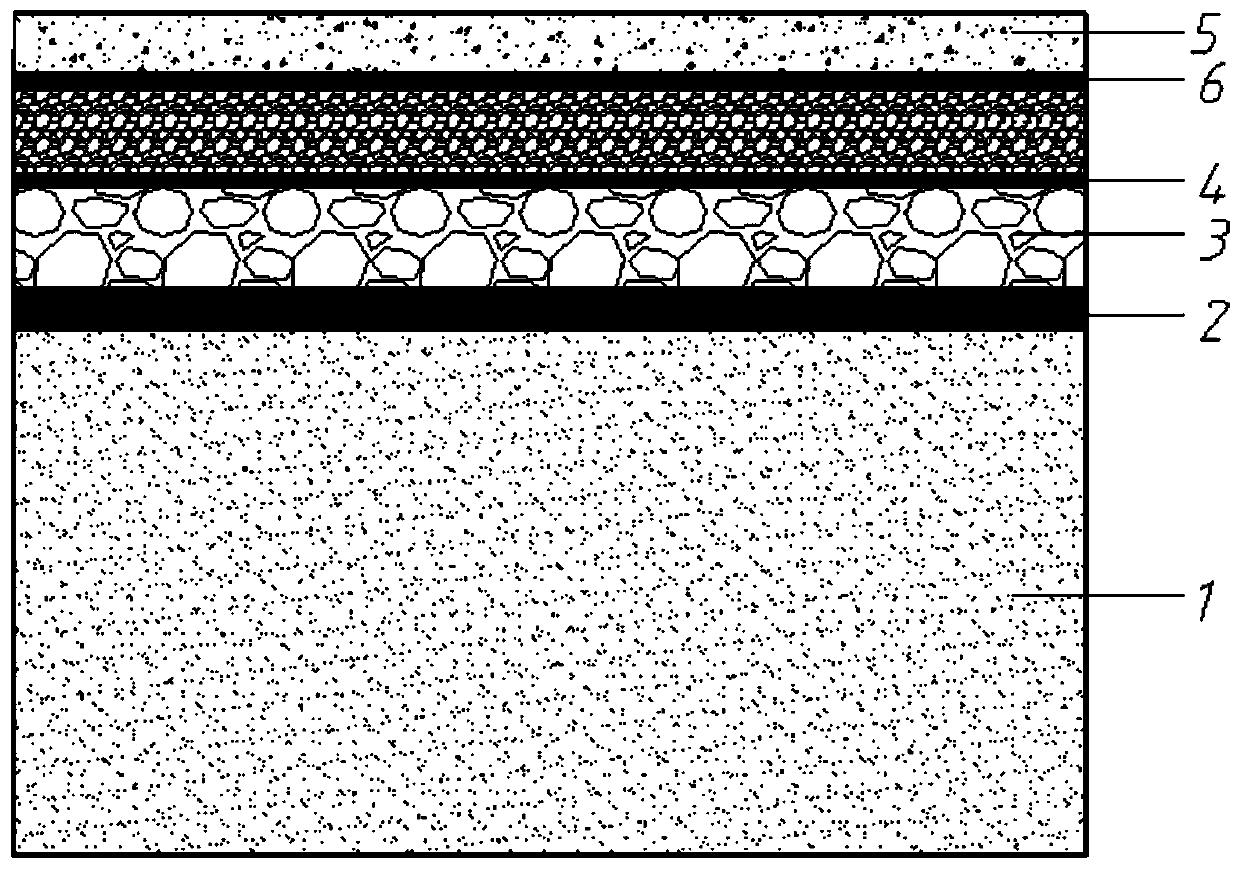

[0056] The multifunctional active composite sealing layer pavement according to the present invention is the original pavement, the active emulsified asphalt layer 2, the first gravel layer 3, the modified emulsified asphalt layer, the second gravel layer 3, the emulsified asphalt layer from bottom to top. Composed of asphalt bonding layer 6 and anti-skid and noise-reducing micro-surface layer.

[0057] The active emulsified asphalt layer 2 is composed of 85% by mass of modified emulsified asphalt and 15% of active agent.

[0058] The mass ratio of each material of the modified emulsified asphalt is 0.4% of asphalt emulsifier, 0.5% of hydrochloric acid, 4.0% of SBR modifier, 67% of base asphalt, 0.3% of stabilizer, and 27.8% of water. The preparation includes the following steps:

[0059] Add LT-CK1 cationic fast-cracking emulsifier into water at 50°C-55°C, adjust the pH value to 1.5-2.5 with hydrochloric acid, and stir well to obtain an emulsifier aqueous solution; heat SK90#...

Embodiment 2

[0075] The multifunctional active composite sealing layer pavement of the present invention comprises a six-layer structure, including the original pavement, the active emulsified asphalt layer 2, the first crushed stone layer 3, the modified asphalt layer, the second crushed stone layer 3 and the fog sealing layer.

[0076] The active emulsified asphalt layer 2 is composed of 95% by mass of modified emulsified asphalt and 5% of active agent.

[0077] The mass ratio of each material of modified emulsified asphalt is: 0.4% of asphalt emulsifier, 0.5% of hydrochloric acid, 4.0% of SBR modifier, 67% of base asphalt, and 28.1% of water. The preparation includes the following steps:

[0078] Add CK-60 cationic fast-cracking asphalt emulsifier into water at 60°C to 65°C, adjust the pH value to 1.8 to 2.3 with hydrochloric acid, and stir well to obtain an aqueous emulsifier solution; heat SK90# base asphalt to 135°C, and heat the heated base Asphalt, emulsifier aqueous solution and S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com