Method for preparing glyceride rich in fish oil and n-3 long-chain polyunsaturated fatty acid by virtue of enzyme method and product of method

A technology of unsaturated fatty acids and fatty acid glycerides, which is applied in the field of enzymatic preparation of n-3 long-chain polyunsaturated fatty acid glycerides rich in fish oil, which can solve the problem of limiting the added value of fish oil derivative products and the content of n-3 polyunsaturated fatty acids No high problems, to achieve the effect of digestion and absorption, high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

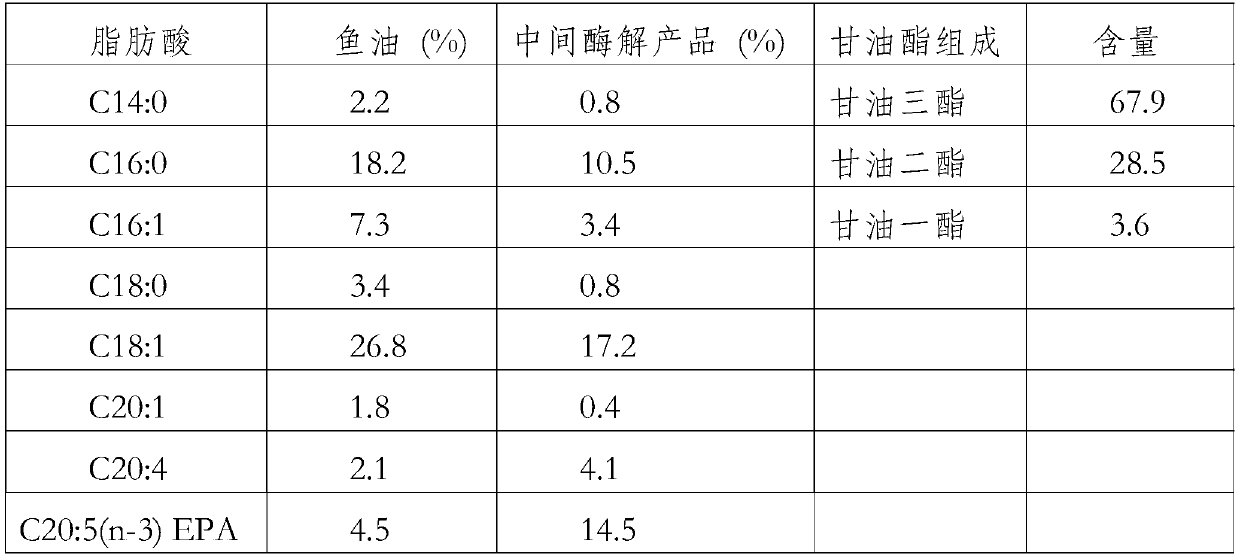

[0025] (1) Tuna oil and ethanol are added in the batch reactor that can be sealed according to the ratio of substrate molar ratio of 1:3 (fish oil / ethanol), add the Lipozyme RM IM of 15wt%, be 25 ℃ at temperature, stirring speed is React for 4 hours under the condition of 400rpm, analyze the content of n-3 long-chain polyunsaturated fatty acids in the intermediate enzymatic hydrolysis product, and see Table 1 for the chemical composition of the intermediate enzymatic hydrolysis product.

[0026] Table 1

[0027]

[0028]

[0029] (2) After the ethanol and fatty acid ethyl ester of the intermediate enzymatic hydrolysis product are removed by vacuum distillation and molecular distillation, the intermediate enzymatic hydrolysis product and glycerin are added to the intermittent Add 3wt% Novozym 435 into the reactor, and react for 12 hours at a temperature of 70° C. and a stirring rate of 800 rpm to obtain a monoglyceride product. The composition of the obtained monoglyceri...

Embodiment 2

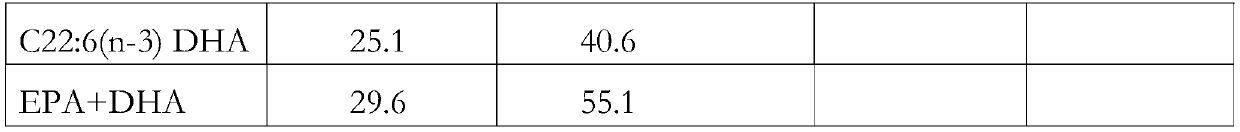

[0041] (1) Squid oil and ethanol are added in the sealable batch reactor according to the ratio of substrate molar ratio of 1:6 (fish oil / ethanol), adding 10wt% Lipozyme TL IM respectively, at a temperature of 30°C, stirring speed React under the condition of 600 rpm for 12 hours to obtain an intermediate enzymatic hydrolysis product rich in n-3 long-chain polyunsaturated fatty acids. The fatty acid composition of the obtained intermediate enzymatic hydrolysis product is shown in Table 6.

[0042] Table 6

[0043] fatty acid fish oil(%) Intermediate hydrolysis products (%) Glyceride composition content C14:0 6.4 2.4 Triglycerides 65.2 C16:0 14.7 7.3 diglycerides 30.3 C16:1 7.5 2.6 monoglyceride 4.5 C18:0 2.3 0.8 C18:1 17.3 8.4 C18:2 2.1 1.1 C18:3 2.4 1.2 C20:1 10.3 12.5 C20:4 1.9 4.1 C20:5(n-3)EPA 8.5 15.7 C22:1 4.1 8.5 C22:6(n-3)DHA 22.1 34.8 ...

Embodiment 3

[0056] (1) Add sardine oil and ethanol into a sealable batch reactor at a ratio of 1:9 (fish oil / ethanol) according to the substrate molar ratio, add 4wt% Lipase AY-30SD respectively, and stir at a temperature of 45°C The reaction was carried out for 8 hours under the condition of 800 rpm, and an intermediate enzymatic hydrolysis product rich in n-3 long-chain polyunsaturated fatty acids was obtained. The fatty acid composition of the obtained intermediate enzymatic hydrolysis product is shown in Table 11.

[0057] Table 11

[0058]

[0059]

[0060] (2) After the ethanol and fatty acid ethyl ester of the intermediate enzymatic hydrolysis product are removed by vacuum distillation and molecular distillation, the intermediate enzymatic hydrolysis product and glycerin are added to the intermittent Add 12wt% Novozym 435 into the reactor, and react for 6 hours at a temperature of 30° C. and a stirring rate of 400 rpm to obtain a monoglyceride product. The composition of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com