Nano titanium dioxide modified graphene oxide rolling liquid and preparation method thereof

A nano-titanium dioxide and titanium dioxide technology is applied in the field of lubricating cold-rolled steel sheets, and can solve the problems of difficulty in realizing the shear-slip effect of graphene oxide sheets, poor thermal stability of graphene oxide, affecting lubrication performance, etc. Avoid direct contact, enhance the effect of lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

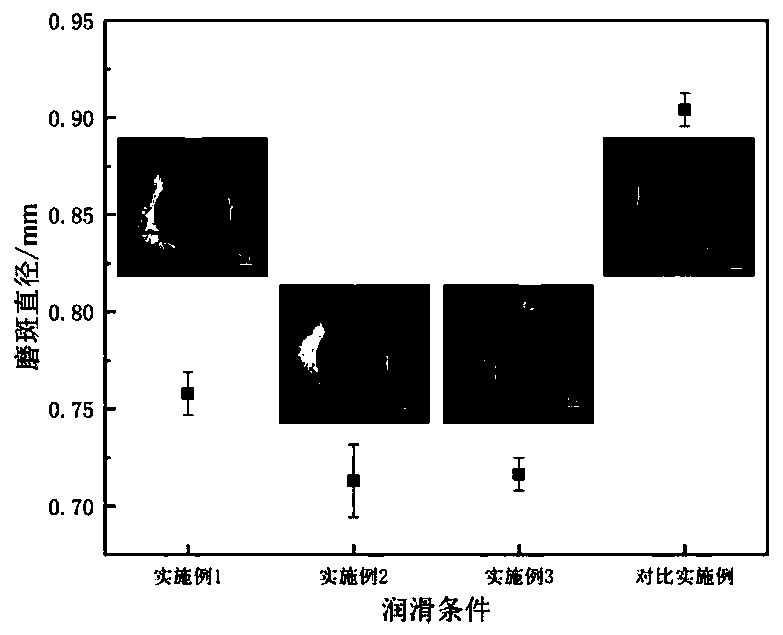

Embodiment 1

[0033] The specific components of the rolling liquid formula that embodiment 1 makes are as follows:

[0034] serial number components Mass / g 1 Oleic acid 0.5 2 Triethanolamine 0.5 3 glycerin 1.0 4 Water-based borate 1.0 5 TiO-modified graphene oxide 0.3 6 Deionized water 96.7

[0035] (1) Add 0.5 g of oleic acid, 0.5 g of triethanolamine, 1.0 g of glycerin, and 1.0 g of water-based borate into 96.7 g of deionized water to completely dissolve in order to obtain a base liquid. Every time an additive is added, it needs to be stirred for 20-30 minutes at a temperature of 50-60°C;

[0036] (2) Add 0.3 g of titanium dioxide-modified graphene oxide into the base liquid, stir and ultrasonically disperse to obtain a uniformly dispersed rolling liquid. The stirring time is 20-30 minutes, the temperature is 50-60°C, and the ultrasonic treatment is 40-50 minutes;

[0037] (3) Use triethanolamine to adjust the pH value of the r...

Embodiment 2

[0039] The specific components of the rolling liquid formula that embodiment 2 makes are as follows:

[0040] serial number components Mass / g 1 Oleic acid 0.5 2 Triethanolamine 0.5 3 glycerin 1.0 4 Water-based borate 1.0 5 TiO-modified graphene oxide 0.5 6 Deionized water 96.5

[0041] (1) Add 0.5 g of oleic acid, 0.5 g of triethanolamine, 1.0 g of glycerin, and 1.0 g of water-based borate into 96.5 g of deionized water in order to completely dissolve to obtain a base liquid. Every time an additive is added, it needs to be stirred for 20-30 minutes at a temperature of 50-60°C;

[0042] (2) Add 0.5 g of titanium dioxide-modified graphene oxide into the base liquid, stir and ultrasonically disperse to obtain a uniformly dispersed rolling liquid. The stirring time is 20-30 minutes, the temperature is 50-60°C, and the ultrasonic treatment is 40-50 minutes;

[0043] (3) Use triethanolamine to adjust the pH value of the r...

Embodiment 3

[0045] The specific components of the rolling liquid formula that embodiment 3 makes are as follows:

[0046] serial number components Mass / g 1 Oleic acid 0.5 2 Triethanolamine 0.5 3 glycerin 1.0 4 Water-based borate 1.0 5 TiO-modified graphene oxide 0.6 6 Deionized water 96.4

[0047] (1) Add 0.5g of oleic acid, 0.5g of triethanolamine, 1.0g of glycerin, and 1.0g of water-based boric acid ester into 96.4g of deionized water and dissolve completely to obtain the base liquid. Every time an additive is added, it needs to be stirred for 20-30 minutes at a temperature of 50-60°C;

[0048] (2) Add 0.6 g of titanium dioxide-modified graphene oxide into the base liquid, stir and ultrasonically disperse to obtain a uniformly dispersed rolling liquid. The stirring time is 20-30 minutes, the temperature is 50-60°C, and the ultrasonic treatment is 40-50 minutes;

[0049] (3) Use triethanolamine to adjust the pH value of the ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com