A kind of aluminum material rolling oil containing coumarin and preparation method thereof

A technology of coumarin and rolling oil, which is applied in the field of lubrication, can solve problems such as unfavorable environmental protection, achieve the effects of improving annealing cleanliness, excellent extreme pressure and anti-wear effects, and reducing rolling pressure and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The formula weight percent of embodiment 1 is: n-hexanol: 8.0%; cinnamon alcohol and cinnamic acid mixture: 4.0%; coumarin: 0.50%; and the balance mineral oil D80.

[0017] Formula by weight, the preparation steps are as follows:

[0018] Mix cinnamon alcohol and n-hexanol in any order, stir until uniform under heating at 50°C, add coumarin, continue stirring until completely dissolved under heating at 50°C, then add the remaining base oil, stir until uniform That's it.

Embodiment 2

[0020] Embodiment 2 formula weight percentage is: n-hexanol, n-heptanol, n-octanol and n-nonanol mixture: 9.0%; Cinnamon alcohol and cinnamon acid mixture: 4.5%; Coumarin: 2%; And balance mineral oil D80, D85 , a mixture of D90 and D95.

[0021] Formula by weight, the preparation steps are as follows:

[0022] Mix the mixture of cinnamon alcohol and cinnamic acid, and the mixture of n-hexanol, n-heptanol, n-octanol and n-nonanol in any order, stir until uniform under heating at 50°C, add coumarin, and continue heating at 50°C Next, stir until completely dissolved, then add the remaining amount of base oil, and stir until uniform.

Embodiment 3

[0024] The weight percent of the formula in Example 3 is: n-nonyl alcohol: 10.0%; cinnamic acid: 5.5%; coumarin: 3.0%; and the balance mineral oil D95.

[0025] Formula by weight, the preparation steps are as follows:

[0026] Mix cinnamon acid and n-nonyl alcohol in any order, stir until uniform under heating at 50°C, add coumarin, continue stirring at 50°C until completely dissolved, finally add the remaining base oil, and stir until Evenly.

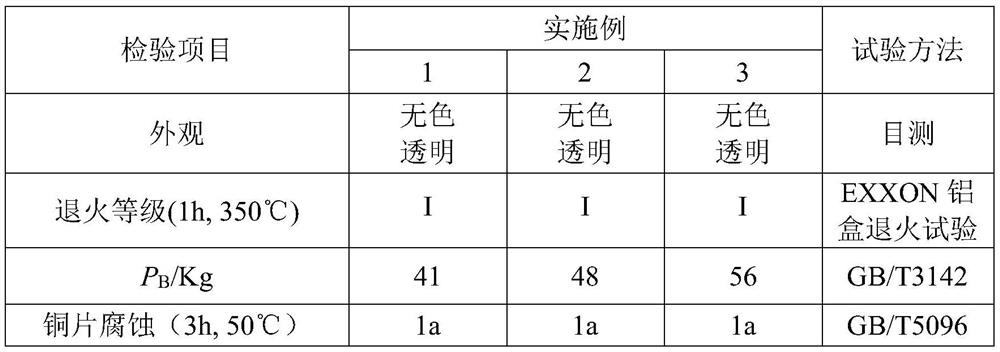

[0027] The product performance index that makes is as follows:

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com