Surface cationized silicon dioxide nanoparticles

A silicon dioxide, cationization technology, applied in the direction of silicon dioxide, silicon oxide, nanotechnology for materials and surface science, etc., can solve the problems of limited foam stability and achieve improved adaptability and good temperature resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Prepare modifier C of silica particles according to the following steps 12 AQAS: In terms of mass components, it includes: 21.34 parts of dodecyldimethyl tertiary amine, 50 parts of absolute ethanol, and 20.86 parts of 3-chloropropyltrimethoxysilane.

[0036] Specific steps

[0037] (1) In terms of parts by mass, weigh 21.34 parts of dodecyldimethyl tertiary amine and put it into a three-neck flask,

[0038] (2) Add 50 parts of absolute ethanol to the three-necked flask in step (1), stir in an oil bath, and slowly heat up to 80°C;

[0039] (3) Add 20.86 parts of 3-chloropropyltrimethoxysilane dropwise to the three-necked flask in step (1), and pass nitrogen gas for 30 minutes;

[0040] (4) Keep the temperature at 80°C and stop the reaction after reflux for 36 hours.

Embodiment 2

[0042] Prepare modified silicon dioxide particles according to the following steps: In terms of mass components, it includes: 24 parts of absolute ethanol, 12.5 parts of pure water, 4.1 parts of ammonia water, 1.6 parts of tetraethyl orthosilicate, C 12 0.5 parts of AQAS modifier.

[0043] Specific steps

[0044] (1) In terms of parts by mass, use a pipette to measure 6.3 parts of absolute ethanol, 12.5 parts of purified water, and 4.1 parts of ammonia water, mix them evenly, and place them in a three-necked flask;

[0045] (2) Put the three-neck flask in step (1) in a magnetic stirring pot and stir at a speed of 300r / min;

[0046] (3) Measure 1.6 parts of ethyl orthosilicate and C 12 0.5 parts of AQAS modifier, measure 17.7 parts of absolute ethanol, mix well and quickly pour into the three-necked flask in step (1), this process requires that the liquid should not touch the bottle wall;

[0047] (4) Increase the stirring speed to 1200r / min. After stirring at high speed for...

Embodiment 3

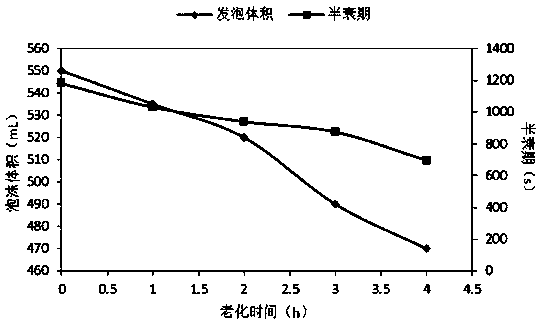

[0049] Example 3 Effect of Modified Nanoparticles on the Stability of the Foam System Formed by Anionic Surfactant or Cationic Surfactant

[0050] The foam system was prepared according to the following steps: In terms of mass components, it included: 0.6 parts of modified nano-silica in Example 2, 199.06 parts of distilled water, and 0.12 parts of cetyltrimethylammonium bromide. 0.22 parts of sodium polyoxyethylene lauryl ether sulfate.

[0051] Specific steps

[0052] (1) Weigh 99.58 parts of distilled water, add 0.12 parts of cetyltrimethylammonium bromide, weigh 99.48 parts of distilled water, add 0.22 parts of polyoxyethylene lauryl ether sodium sulfate, and place in an ultrasonic water bath at 45 Heat at ℃, ultrasonically disperse for 20min;

[0053] (2) After the two solutions in step (1) are clear and transparent, weigh 0.3 parts of the modified silica particles in Example 2, respectively, add them to the two solutions and stir gently with a glass rod to disperse the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com