Non-stick coating layer and coating process thereof

A non-stick and coating technology, which is applied in coatings, devices for coating liquid on the surface, epoxy resin coatings, etc., can solve the problems of not being able to meet the requirements of processing molds, short service life, poor comprehensive performance, etc., and achieve excellent performance. Viscous, long service life, good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047]A non-stick coating, comprising the following raw materials in parts by weight:

[0048] 40-50 parts of epoxy acrylate,

[0049] 25-32 parts of fluorine-containing polyacrylic acid ester,

[0050] 25-32 parts of poly(vinylidene fluoride-trifluoroethylene),

[0051] 10-15 parts of polytetrafluoroethylene powder,

[0052] 2.5-4 parts of suspending agent, 1-1.4 parts of leveling agent, 1.5-2 parts of curing agent.

[0053] Preferably, the non-stick coating comprises the following raw materials in parts by weight:

[0054] 45 parts of epoxy acrylate,

[0055] 27.5 parts of fluorine-containing polyacrylic acid ester,

[0056] Poly(vinylidene fluoride-trifluoroethylene) 28.5 parts,

[0057] 13 parts of polytetrafluoroethylene powder,

[0058] Suspending and dispersing agent 3.4 parts, leveling agent 1.2 parts, curing agent 1.7 parts.

[0059] Preferably, the suspending and dispersing agent is a copolymer of vinylpyrrolidone and vinylimidazole.

[0060] Preferably, the...

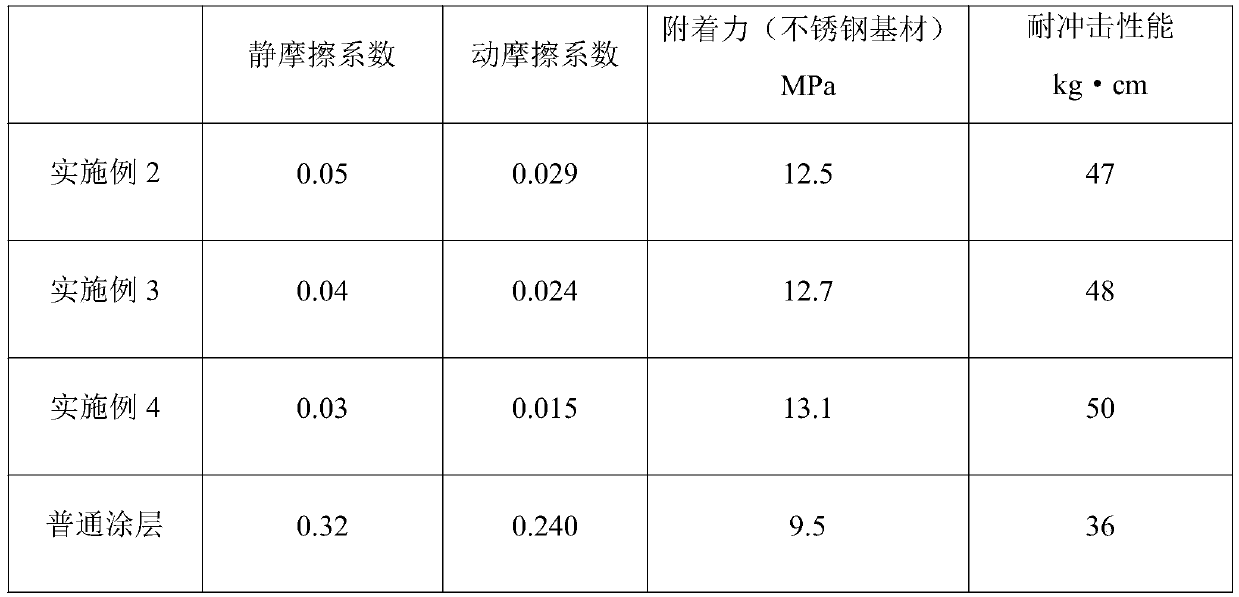

Embodiment 2

[0071] A non-stick coating, comprising the following raw materials in parts by weight:

[0072] 40 parts of epoxy acrylate,

[0073] 25 parts of fluorine-containing polyacrylic acid ester,

[0074] 25 parts of poly(vinylidene fluoride-trifluoroethylene),

[0075] 10 parts of polytetrafluoroethylene powder,

[0076] Suspending dispersant 2.5 parts, leveling agent 1, curing agent 1.5 parts.

[0077] In this embodiment, the suspending and dispersing agent is a copolymer of vinylpyrrolidone and vinylimidazole.

[0078] In this embodiment, the leveling agent is AC-3777.

[0079] In this embodiment, the curing agent is a mixture of CF-6501 epoxy curing agent, dicyandiamide and dimethylimidazole.

[0080] In the present embodiment, the mass ratio of CF-6501 epoxy curing agent, dicyandiamide and dimethylimidazole in the mixture of CF-6501 epoxy curing agent, dicyandiamide and dimethylimidazole is 1:0.7:0.02.

[0081] In this embodiment, the particle size of the polytetrafluoroe...

Embodiment 3

[0089] A non-stick coating, comprising the following raw materials in parts by weight:

[0090] 50 parts of epoxy acrylate,

[0091] 32 parts of fluorine-containing polyacrylic acid ester,

[0092] 32 parts of poly(vinylidene fluoride-trifluoroethylene),

[0093] 15 parts of polytetrafluoroethylene powder,

[0094] 4 parts of suspension dispersant, 1.4 parts of leveling agent, 2 parts of curing agent.

[0095] In this embodiment, the suspending and dispersing agent is a copolymer of vinylpyrrolidone and vinylimidazole.

[0096] In this embodiment, the leveling agent is AC-3777.

[0097] In this embodiment, the curing agent is a mixture of CF-6501 epoxy curing agent, dicyandiamide and dimethylimidazole.

[0098] In the present embodiment, the mass ratio of CF-6501 epoxy curing agent, dicyandiamide and dimethylimidazole in the mixture of CF-6501 epoxy curing agent, dicyandiamide and dimethylimidazole is 1:0.8:0.04.

[0099] In this embodiment, the particle size of the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com