Amphoteric polycarboxylate superplasticizer and preparation method thereof

A technology of amphoteric polycarboxylate and water reducer, which is applied in the field of polycarboxylate water reducer for cement concrete. The effect of low temperature and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

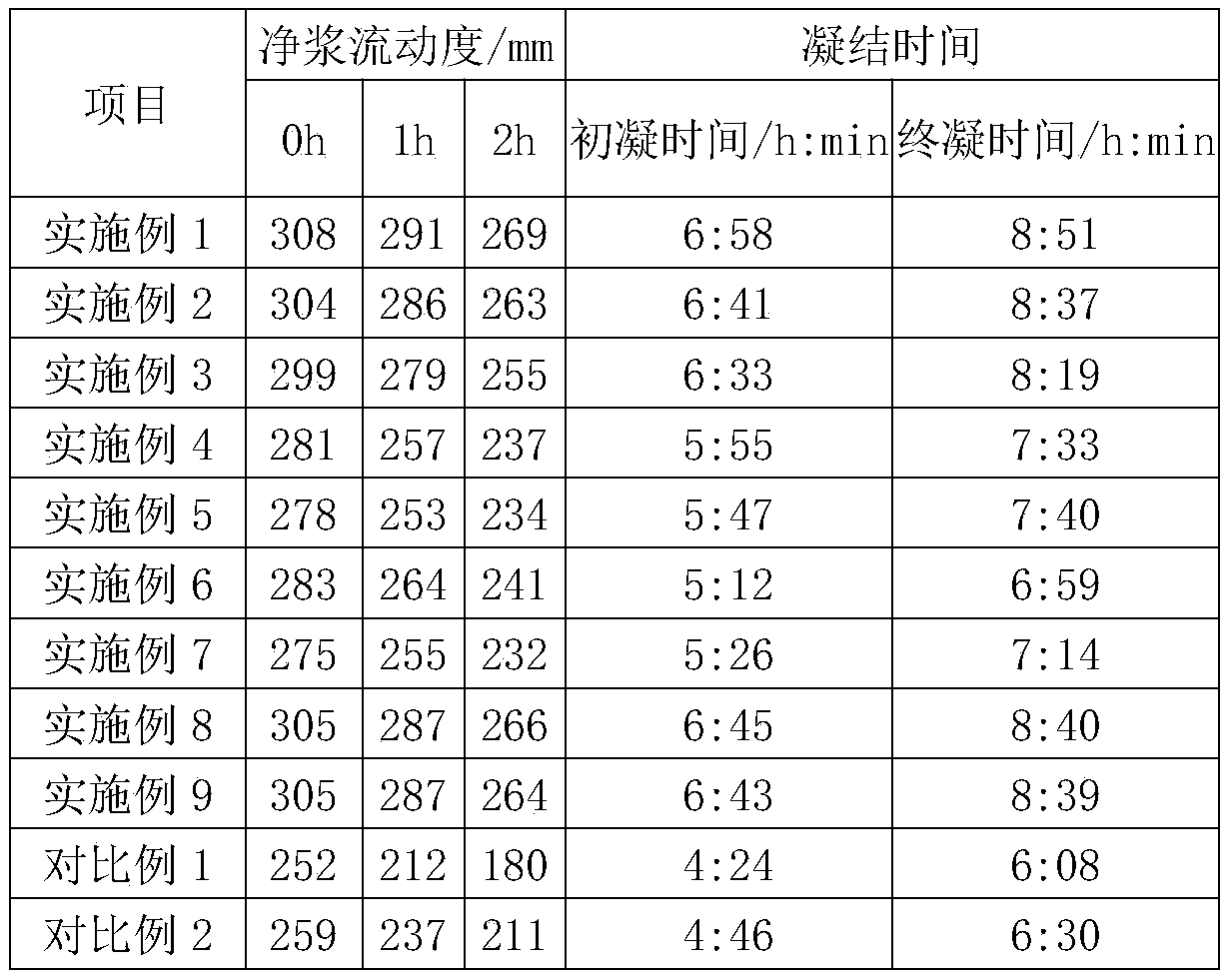

Examples

Embodiment 1

[0034] Preparation of acrylamide monomer containing phenyl ether:

[0035] Add 30 parts of organic solvent dichloromethane, 10 parts of 4,4'-diaminodiphenyl ether, 5 parts of acid-binding agent triethylamine into the reaction kettle, stir well, and cool the mixture to 0°C; add 4.5 parts of propylene The mixed solution of acid chloride and 10 parts of dichloromethane was added dropwise to the reactor, and the reaction was continued at constant temperature for 4 h; with 10 parts of saturated NaHCO 3 Wash the solution in the reaction kettle for 3 times, separate the liquid to obtain the inorganic phase, filter, evaporate the solvent, and separate the residue with an ethyl acetate / petroleum ether (V / V=1 / 5) column to obtain a white acrylamide monomer containing phenyl ether .

[0036] Preparation of amphoteric polycarboxylate superplasticizer:

[0037] Add M to the reactor w=2400g / mol, 100 parts of isopentenol polyoxyethylene ether with a hydroxyl value of 21-26mgKOH / g, 5 parts ...

Embodiment 2

[0039] The rest is the same as in Example 1, except that the amount of acrylamide monomer containing phenylene ether is 5 parts, and that of diacetone acrylamide is 3 parts.

Embodiment 3

[0041] The rest is the same as in Example 1, except that the amount of phenylene ether-containing acrylamide monomer is 8 parts, and the amount of diacetone acrylamide is 3 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com