Preparation method of high-voltage lithium-ion battery

A lithium-ion battery, high-voltage technology, used in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, battery electrodes, etc., can solve problems such as poor conductivity, achieve the effect of improving conductivity, wide application prospects, and avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Pure phase LiCoPO 4 Preparation of cathode material:

[0025] 0.01 mol LiNO 3 , 0.01 mol Co(NO 3 ) 2 ·6H 2 O and 0.02 mol C 6 h 8 o 7 ·H 2 O was dissolved in 40ml deionized water and stirred for 30 minutes, then 0.01 mol (NH 4 ) 2 HPO 4 Add dropwise to the above mixed solution and stir for 3 hours; then heat the solution continuously in a constant temperature water tank at 85°C until a gel is formed, dry the gel in an oven at 100°C for 12 hours, take it out and grind it at 600°C C was directly calcined under air atmosphere for 8 hours to obtain pure phase LiCoPO 4 Cathode material.

[0026] 2) Preparation of electrolyte solution with additives:

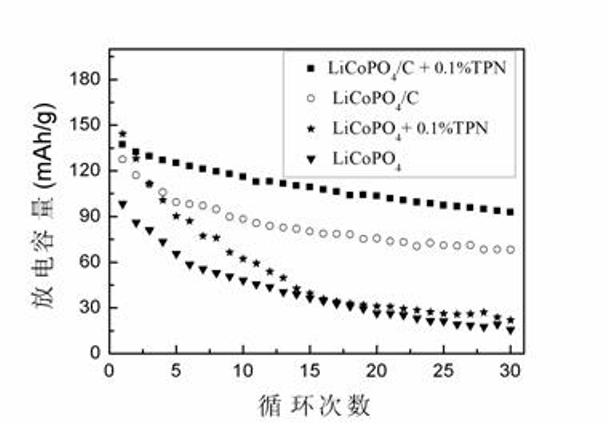

[0027] In a glove box with a high-purity argon atmosphere, 1.0 M LiFP 6 - Add 0.1 % and 0.5 % thiophene (TPN) additives to EC / DMC / EMC, stir until uniform, and obtain the optimized electrolyte.

[0028] LiCoPO 4 , conductive agent, and binder (PTFE) were mixed at a mass ratio of 75:20:5, pressed into a circula...

Embodiment 2

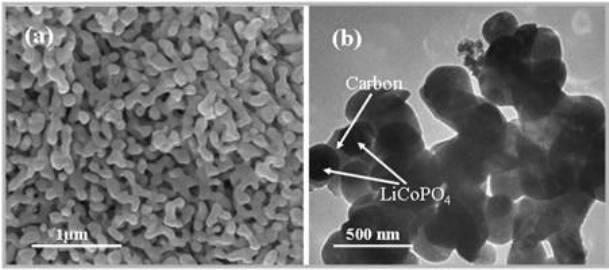

[0030] 1) Carbon-coated cathode composite material LiCoPO 4 Preparation of / C

[0031] 0.01 mol LiNO 3 , 0.01 mol Co(NO 3 ) 2 ·6H 2 O and 0.02 mol C 6 h 8 o 7 ·H 2 O was dissolved in 40ml deionized water and stirred for 40 minutes, then 0.01 mol (NH 4 ) 2 HPO 4 It was added dropwise to the above mixed solution and stirred for 3 hours. Then the solution was continuously stirred and heated in a constant temperature water bath at 85°C until a gel was formed, and the gel was dried in an oven at 100°C for 12 hours.

[0032] After the xerogel was ground, it was pre-fired in a tube furnace at 350 °C under an argon atmosphere for 2 hours. The calcined product was taken out and ground, then pressed into tablets at 20 MPa, and heated in a microwave oven for 11 minutes. Finally, the product was calcined in an air atmosphere at 500°C for 4 hours to remove a large amount of carbon, and finally LiCoPO with a network structure was obtained. 4 / C composite material, elemental an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com