A kind of method of synthesizing polyacrylonitrile copolymer

A technology for polyacrylonitrile and copolymers, which is applied in the field of synthesizing polyacrylonitrile copolymers, which can solve the problems of unfavorable increase in the molecular weight of polyacrylonitrile products, difficult control, cumbersome process, etc., and achieves reduced transfer probability, easy heat dissipation, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present embodiment provides a kind of method for synthesizing polyacrylonitrile copolymer, concrete steps comprise:

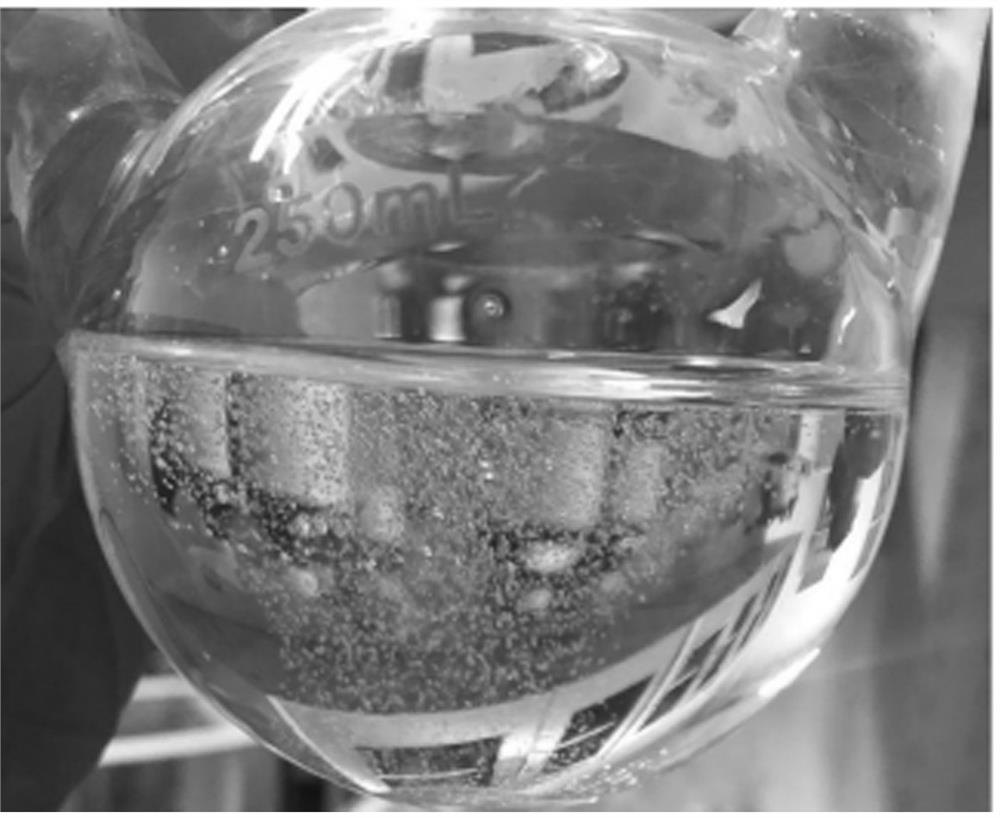

[0024] In a 250ml flask, first add 0.264g ammonium persulfate and 0.66g itaconic acid, 32.34g acrylonitrile monomer, 114.66g dimethyl sulfoxide, 2.34g deionized water, mix and dissolve evenly to obtain a solution to be polymerized, and then Move the flask into a constant temperature water bath at 65°C, use magnetic stirring, and react for 4 hours under the protection of nitrogen to obtain a uniform transparent viscous liquid; figure 1 As shown, the homogeneous transparent viscous liquid is transparent.

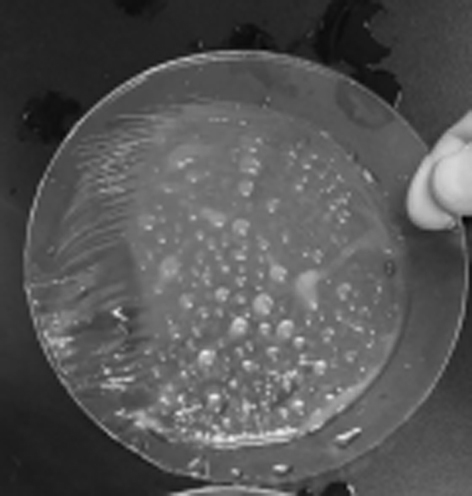

[0025] After the reaction is over, remove the flask from the water bath and add cold water to terminate the polymerization reaction. The obtained polymer solution is pressed into a film, soaked and dried to obtain a polyacrylonitrile copolymer. The appearance of the polyacrylonitrile copolymer is shown in the figure figure 2 Shown, its conversion r...

Embodiment 2

[0027] The present embodiment provides a kind of method for synthesizing polyacrylonitrile copolymer, concrete steps comprise:

[0028] In a 250ml flask, first add 0.198g of ammonium persulfate and 0.66g of itaconic acid, then add 32.34g of acrylonitrile monomer, 109.98g of dimethyl sulfoxide, and 7.02g of deionized water, mix and dissolve evenly, and then move the flask into Put it in a constant temperature water bath at 58°C, use magnetic stirring, and react for 4 hours under the protection of nitrogen to obtain a uniform transparent viscous liquid; image 3 As shown, the homogeneous transparent viscous liquid is transparent.

[0029] After the reaction is over, the flask is removed from the water bath and cold water is added to terminate the polymerization reaction, and the obtained polymer solution is pressed into a film, soaked and dried to obtain a polyacrylonitrile copolymer. Its conversion rate is 80% after testing.

Embodiment 3

[0031] The present embodiment provides a kind of method for synthesizing polyacrylonitrile copolymer, concrete steps comprise:

[0032] In a 250ml flask, first add 0.33g of azobisisobutylamidine hydrochloride and 0.66g of itaconic acid, then add 32.34g of acrylonitrile monomer, 111.15g of dimethylformamide, and 5.85g of deionized water. After mixing and dissolving evenly, the flask was moved into a constant temperature water bath at 65°C, stirred by magnetic force, and reacted for 6 hours under the protection of nitrogen.

[0033] After the reaction is over, the flask is removed from the water bath and cold water is added to terminate the polymerization reaction, and the obtained polymer solution is pressed into a film, soaked and dried to obtain a polyacrylonitrile copolymer. Its conversion rate was tested to be 51%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com