Preparation method of rotary carbon/carbon composite material

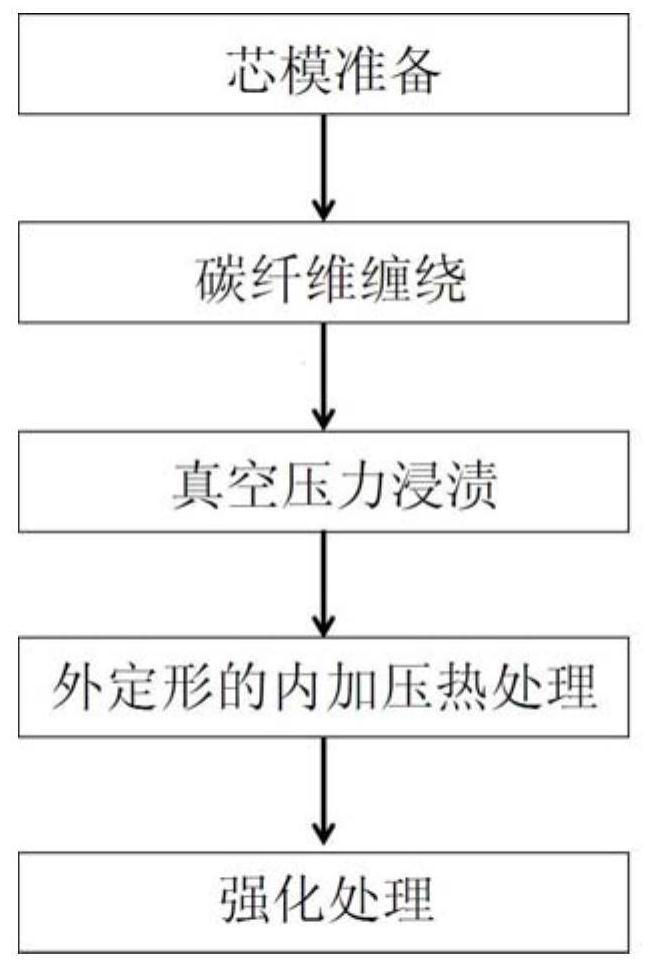

A technology of carbon composite materials and rotators, which is applied in the field of preparation of rotator-like carbon/carbon composite materials, can solve problems such as shortening the preparation cycle, achieve the effects of shortening the densification cycle, improving the structure, and increasing the preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation method of this embodiment comprises the following steps:

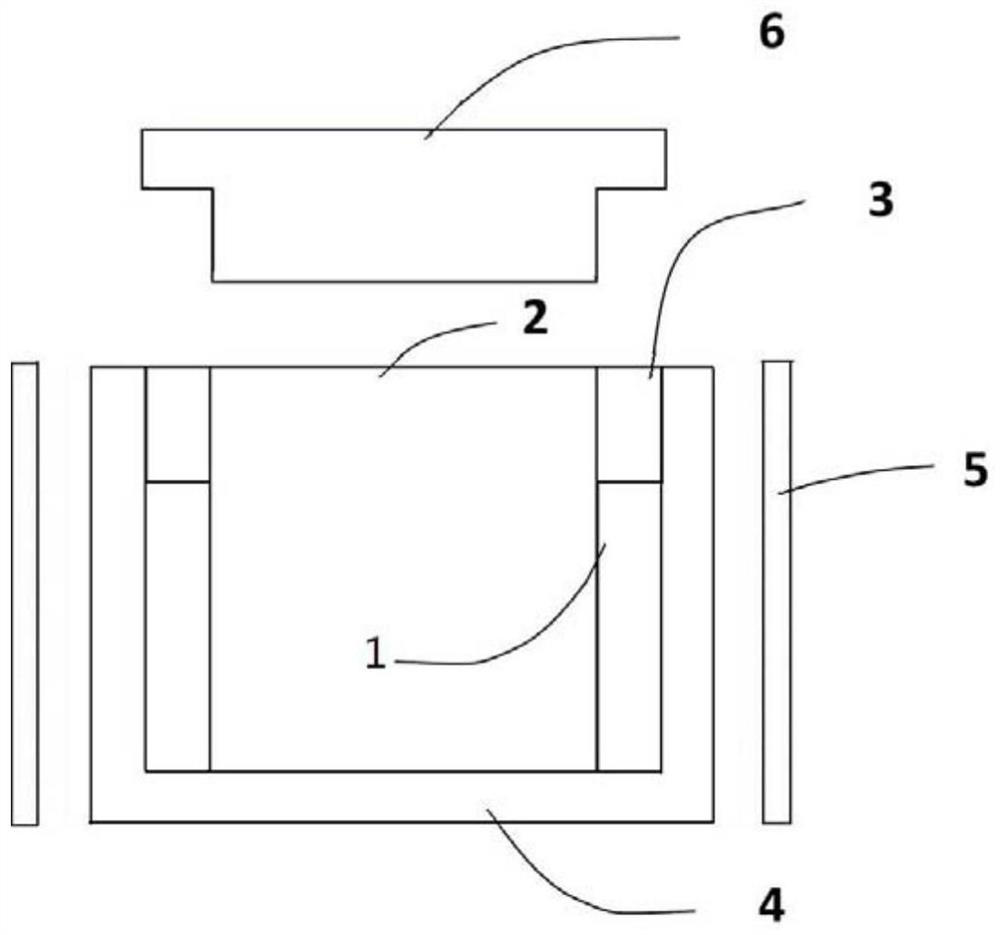

[0041] Step 1. Mandrel preparation: Determine the inner diameter of the target product cylindrical carbon / carbon composite material of 660mm, outer diameter of 690mm, wall thickness of 30mm, length of 500mm, high temperature elliptical deformation not exceeding 3mm, and density not less than 1.65g / cm 3 , the hoop tensile strength is not less than 190MPa, and the interlaminar shear strength is not less than 25MPa. According to the target product cylindrical carbon / carbon composite material and the heat treatment deformation law of the continuous carbon fiber used, the outer surface shape and the target product cylindrical shape are designed. Shape The inner surface of the carbon / carbon composite material has the same shape, a length of 600mm and an outer diameter of 586mm. Lay out a PTFE release cloth and apply silicone grease as a release agent on the PTFE release cloth;

[0042] Step 2. Carbon ...

Embodiment 2

[0050] The preparation method of this embodiment comprises the following steps:

[0051] The difference between this embodiment and embodiment 1 is: in step 1, the design density of the target product charcoal / charcoal pot is not less than 1.45g / cm 3 , the interlayer bonding strength is not less than 15MPa, the hoop tensile strength index is not less than 120MPa, the core mold material is electrode graphite, and the outer diameter of the core mold is 597mm; in step 2, the spiral winding angle is 85°, and the hoop winding angle is 87°, the inner diameter of the wrapping piece is 597mm, the outer diameter is 660mm, and the thickness is 31.5mm; in step 4, the inner diameter of the hot-pressing die is 670mm, and the gap with the wrapping piece is 5mm, and the process of the inner pressure heat treatment is: (1) first Under the pressure of 4MPa~8MPa, the temperature is increased to 150℃ at the rate of 20℃ / min~35℃ / min; (2) then under the pressure of 4MPa~8MPa, the temperature is inc...

Embodiment 3

[0054] The preparation method of this embodiment comprises the following steps:

[0055] The difference between this embodiment and embodiment 1 is: in step 1, the design density of the target product charcoal / charcoal pot is not less than 1.55g / cm 3 , the interlayer bonding strength is not less than 22MPa, the hoop tensile strength index is not less than 170MPa, the core mold material is electrode graphite, and the outer diameter of the core mold is 609mm; in step 2, the spiral winding angle is 55°, and the hoop winding angle is 89°, the inner diameter of the wrapping piece is 609mm, the outer diameter is 690mm, and the thickness is 40.5mm; in step 4, the inner diameter of the hot-pressing die is 696mm, and the gap with the wrapping piece is 3mm, and the process of the inner pressure heat treatment is: (1) first Under the pressure of 4MPa~8MPa, the temperature is increased to 150℃ at the rate of 20℃ / min~35℃ / min; (2) then under the pressure of 4MPa~8MPa, the temperature is inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com