Preparation method and application of MoSe2/ZnCdS nanoparticles

A nanoparticle and nanosheet technology, which is used in the preparation of MoSe2/ZnCdS composite materials and in the application field of photocatalytic hydrogen production, can solve the problems of reduced catalytic activity, low surface area, and low electron hole separation efficiency, and achieves excellent results. The effect of hydrogen production performance, wide application, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

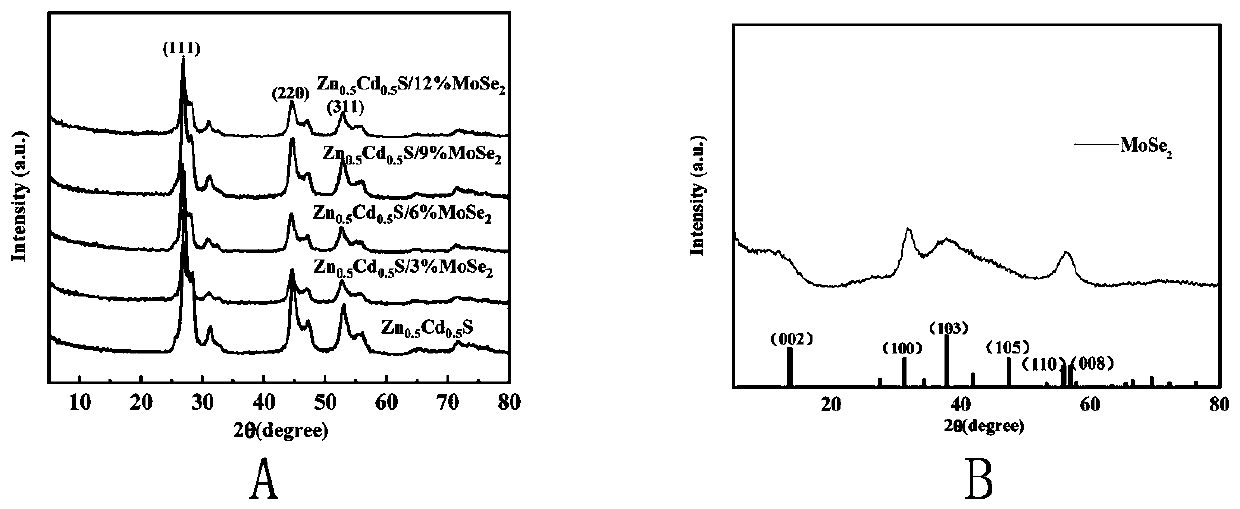

[0027] 1) Add 5mmol Zn(Ac) 2 2H 2 O, 5 mmol Cd(Ac) 2 2H 2 O and 12.5 mmol thioacetamide were dissolved in 40 mL distilled water. Then 10 mL of 4M NaOH aqueous solution was added to the above solution under vigorous stirring until a homogeneous solution was formed. The solution was transferred into a Teflon-lined autoclave, and the autoclave was sealed and kept in an oven at 180 °C for 24 h. After the autoclave was naturally cooled at room temperature, the obtained yellow product was collected, centrifuged several times with water and ethanol, and dried in an oven at 60 °C for 8 h. The resulting Zn 0.5 CD 0.5 S solid solution.

[0028] 2) Add 0.304 gNaBH 4 , 0.316 g of Se powder, and 0.57 g of sodium molybdate were dissolved in 75 mL of deionized water, and stirred evenly. The black precipitate was washed three times with deionized water and absolute ethanol, and dried at 60 °C to obtain MoSe 2 Nanosheets.

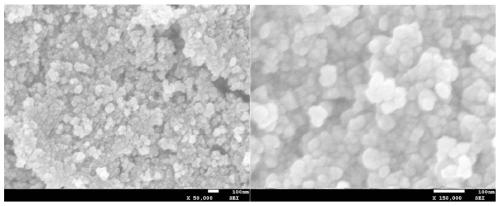

[0029] 3) Add 5mL of ethanol into a 10ml centrifuge tube, m...

Embodiment 2

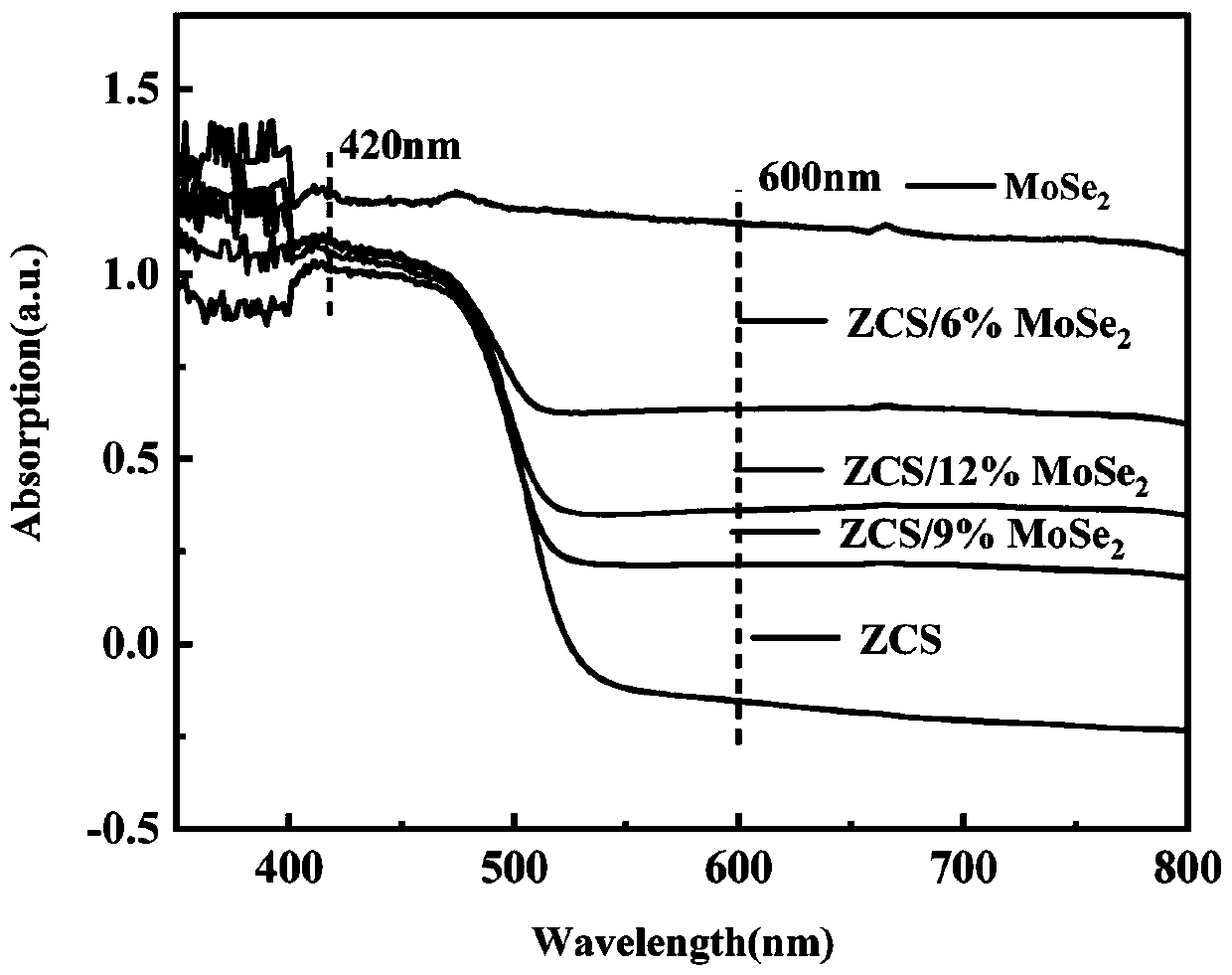

[0031] 1) MoSe obtained in Example 1 2 / ZnCdS composite catalyst for visible light photocatalytic hydrogen production.

[0032] Under visible light irradiation, hydrogen production experiments were carried out in a closed quartz reaction system. The temperature of the reaction system was kept at 6 °C by cooling circulating water, and 20 mg of the catalyst was dispersed in 80 mL of lactic acid and deionized aqueous solution (8 mL of lactic acid, 72 mL of water), in which lactic acid was used as a sacrificial agent, and the air was completely removed under continuous stirring, and a 300W Xe arc lamp with a 420 nm filter (CEL-HXF300) was used as a light source, and online gas chromatography (FULI, GC -7920) for hydrogen evolution analysis. After the light starts, samples are taken every 1 hour to get Figure 6 The hydrogen production histogram is shown. It can be concluded that MoSe 2 When the addition amount is 9% MoSe 2 The hydrogen production capacity of the / ZnCdS compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com