Double-sided heat collection type composite solar heat absorber and method

A solar heat absorber and double-sided heat collection technology, which is applied to solar heat collectors, solar heat collectors using working fluids, solar thermal energy, etc., can solve the loss of solar radiation, uneven heating of working fluid, and increase production costs. and other problems, to achieve the effect of reducing unnecessary heat dissipation, increasing the utilization rate of energy, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with specific embodiment the present invention is described in further detail, described is explanation of the present invention rather than limitation.

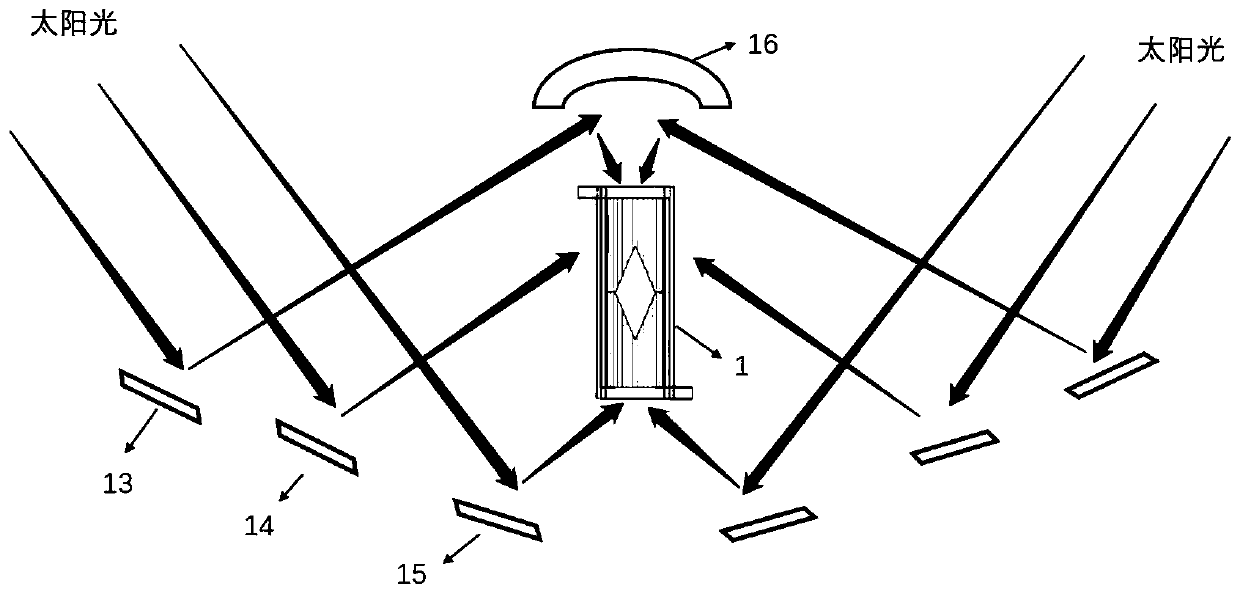

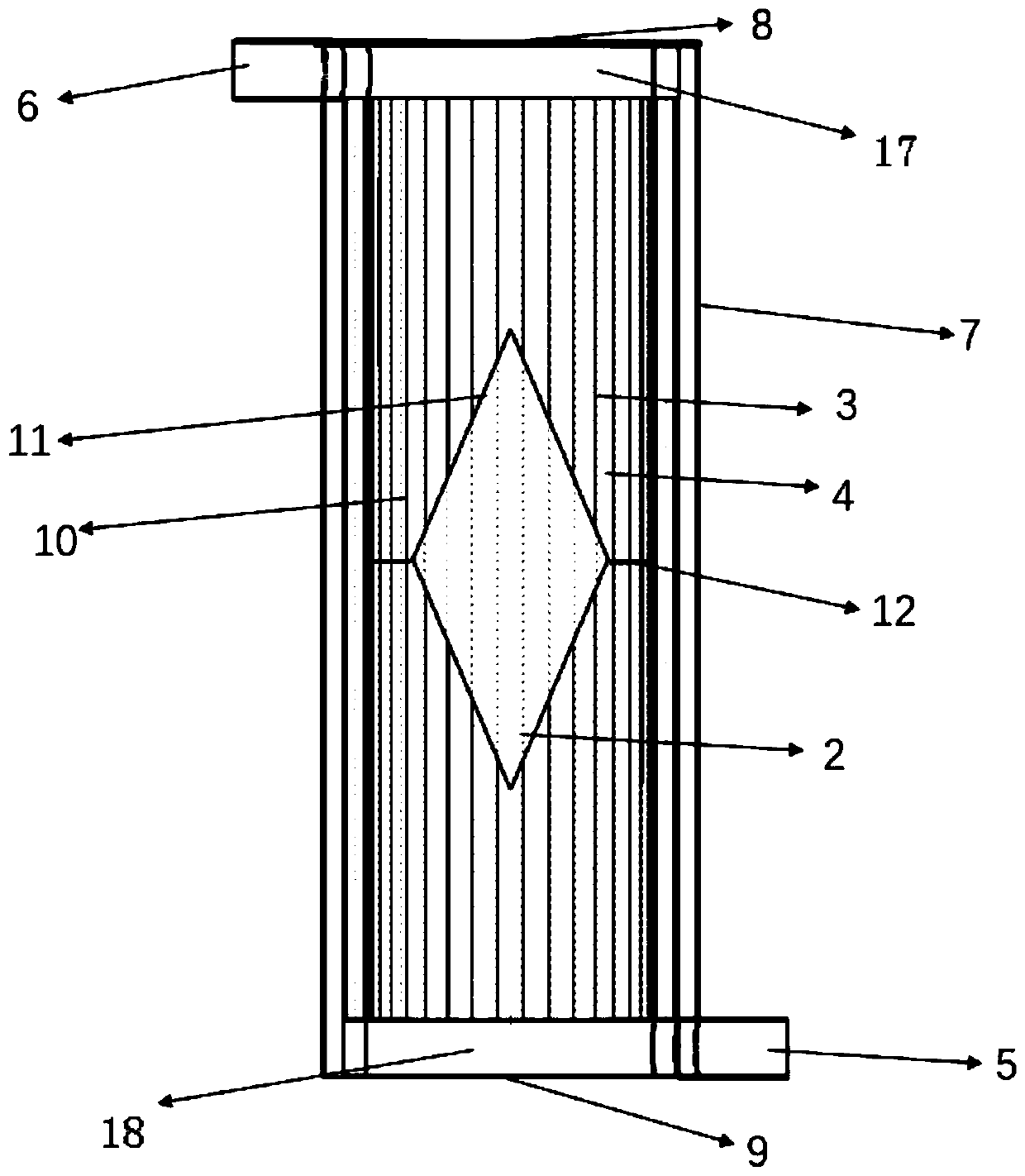

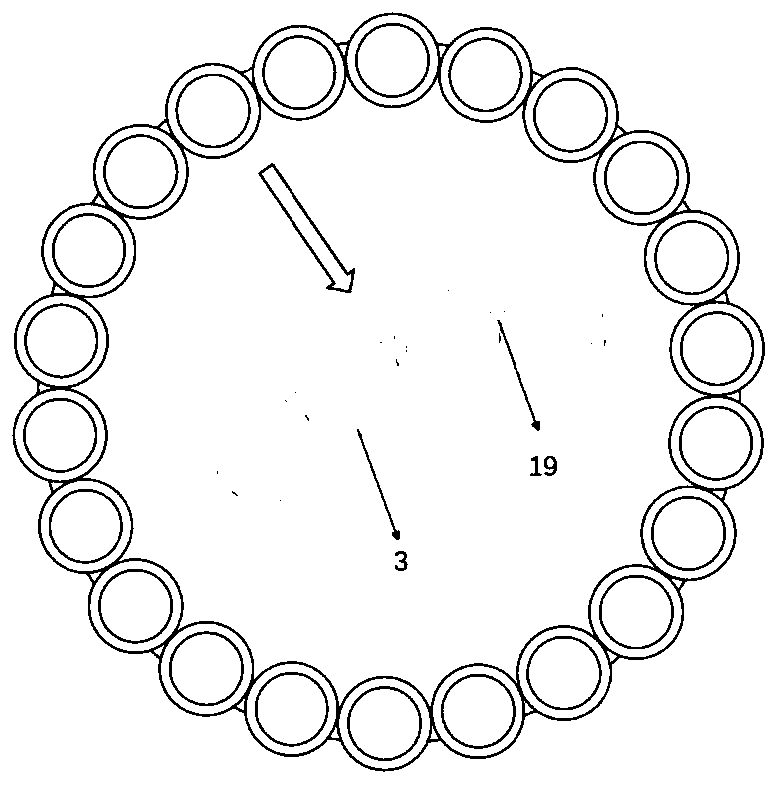

[0045] Such as figure 1 As shown, a double-sided composite solar heat absorber includes a heat absorber body 1 , an inner top heliostat 13 , an outer heliostat 14 , an inner bottom heliostat 15 and a curved reflector 16 .

[0046]The arc reflector 16 is fixed above the heat absorber body 1, a part of the solar energy is projected to the inner top heliostat 13, reflected to the arc reflector 16, and then projected to the double cone through the transparent upper cover 8 of the heat absorber after focusing and reflecting. The upper side of the body 2 is evenly projected onto the inner surface of the heat-absorbing pipe 3 through reflection.

[0047] Part of the solar energy is projected to the inner bottom heliostat 15, and after reflection, it is projected to the underside of the bicone 2 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com