Normalized DH36 steel plate for wind power and preparation method thereof

A DH36, steel plate technology, applied in the field of iron and steel metallurgy, can solve the problems of low pass rate of thick wind power steel plates, no relevant patents and reports retrieved, poor performance uniformity and stability, etc., to achieve low comprehensive production costs and improve internal Quality, Guaranteed Purity and Effects of Cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

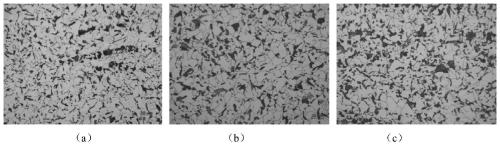

Image

Examples

Embodiment

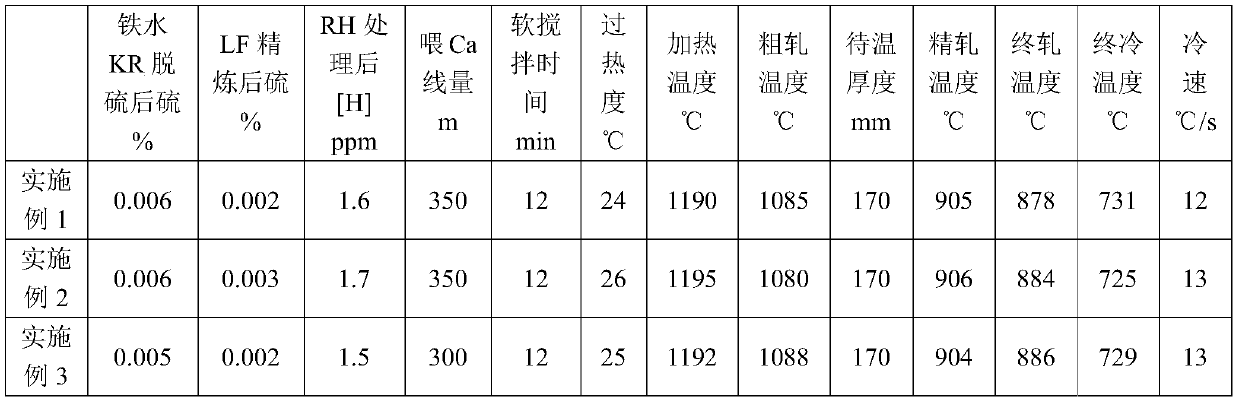

[0023] The process route is as follows: Weigh the components as required to obtain molten iron, KR desulfurization of molten iron, converter smelting, LF refining, RH vacuum treatment, slab continuous casting, slab reheating, rough rolling, intermediate slab cooling, finish rolling , Rapid cooling of steel plate, off-line stack cooling, ultrasonic flaw detection, shot blasting, normalizing, accelerated cooling of steel plate. The control parameters of the smelting furnace and rolling process of this embodiment are shown in Table 1, the smelting composition of the smelting furnace is shown in Table 2, the control parameters of the heat treatment process are shown in Table 3, and the mechanical properties of the steel plate after heat treatment are shown in Table 4.

[0024] Table 1 Example smelting furnaces and rolling process control parameters

[0025]

[0026] Table 2 Example smelting furnace smelting composition

[0027] C% Si% Mn% P% S% Nb% Ti% Al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com