Intelligent extraction equipment for extracting wool fat from wool

An extraction equipment and lanolin technology, applied in the field of lanolin, can solve the problems of reducing the recovery rate, taking away the waste of liquid, changing the physical and chemical properties of the liquid, etc., to achieve improved separation and subsequent extraction, high degree of automation, and improved mixing rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

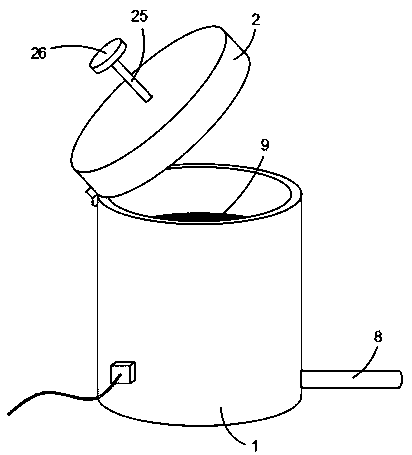

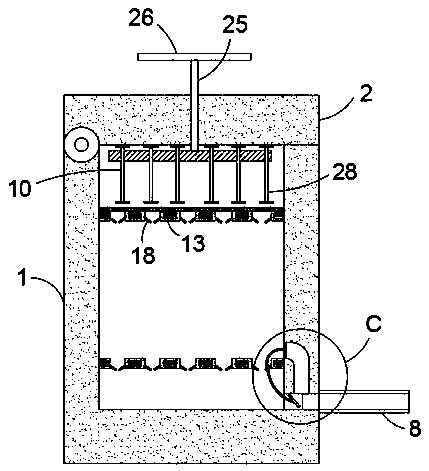

[0030] Such as Figure 1-10 As shown, an intelligent extraction device for extracting lanolin from wool includes a liquid-taking cylinder body 1 and a barrel cover 2. The barrel cover 2 is connected to the upper end of the liquid-taking cylinder body 1 through a hinge, and the liquid-taking cylinder body 1 is equipped with Drive chamber 3 is arranged, and drive chamber 3 is an arc-shaped airtight chamber, and the inwall of drive chamber 3 is fixedly connected with drive motor 4, and drive motor 4 is prior art, does not go into details here, the same on the drive shaft of drive motor 4 The shaft is fixedly connected with a first threaded rod 5, the first threaded rod 5 is a reciprocating screw rod, the end of the first threaded rod 5 away from the drive motor 4 is fixedly connected with the inner wall of the drive chamber 3, and the first threaded rod 5 is threadedly connected with a moving Plate 6, the moving plate 6 can move back and forth on the first threaded rod 5, the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com