Coal catalytic gasification safety monitoring system and monitoring method thereof

A safety monitoring system and coal catalytic gasification technology, applied in the field of coal chemical industry, can solve problems such as leakage, abrasive process medium, explosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

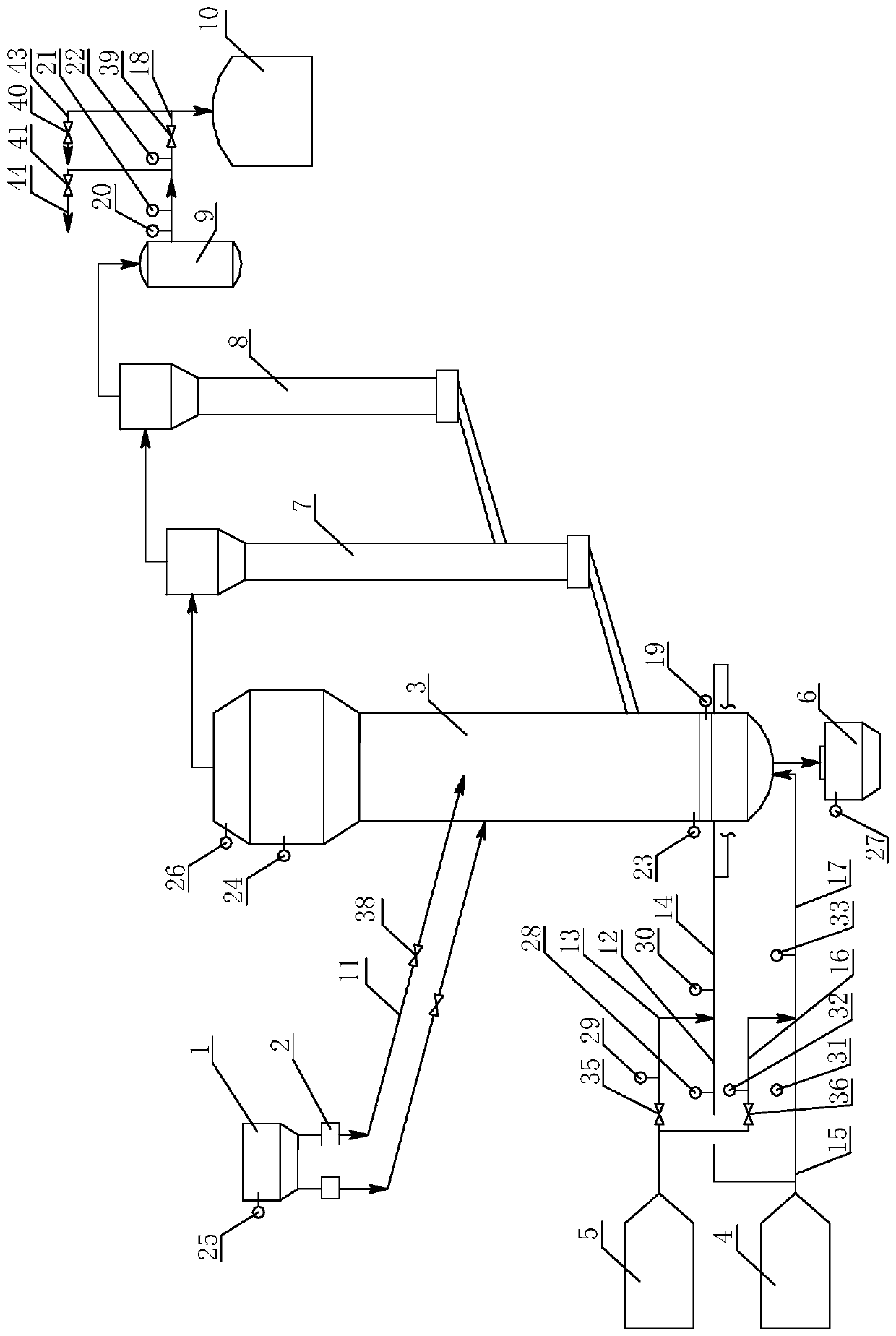

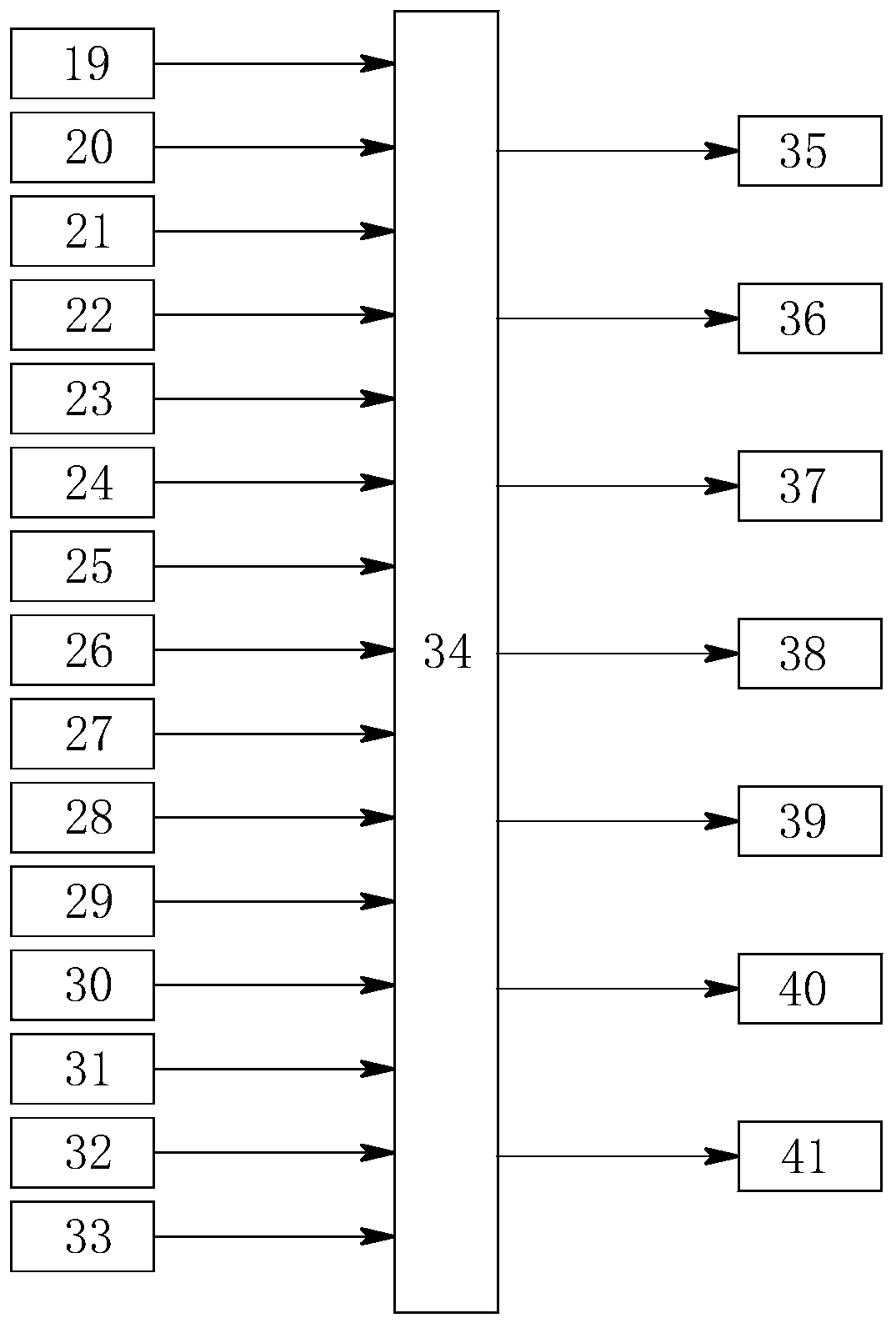

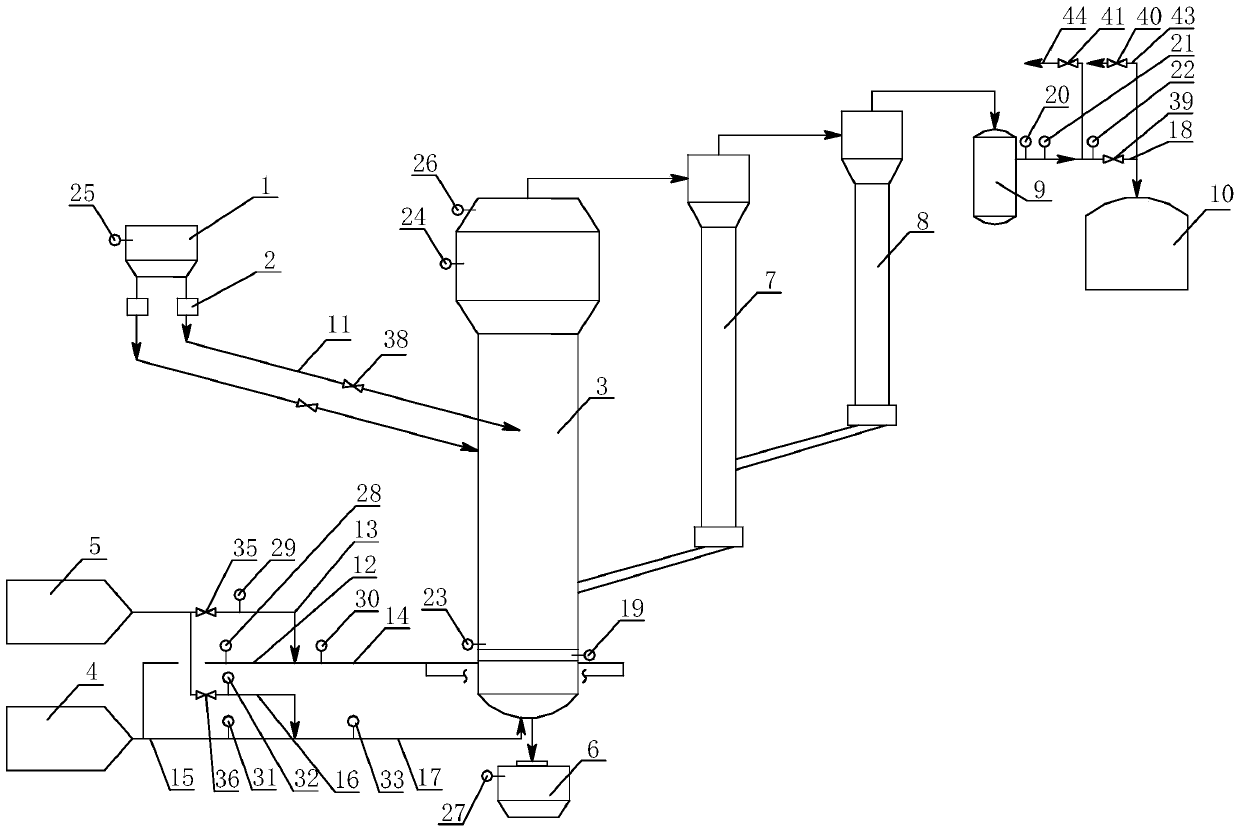

[0063] Such as figure 1 , figure 2 The coal catalytic gasification safety monitoring system shown includes a coal catalytic gasification device, a detection mechanism, a PLC controller 34 and an actuator;

[0064] The detection mechanism is connected with the PLC controller 34 by wired or wireless; the detection mechanism is used to detect the operating temperature, operating pressure and oxygen content data of the coal catalytic gasification device, and the detected operating temperature, operating pressure and oxygen content data transmitted to the PLC controller 34;

[0065] The PLC controller 34 is connected to the actuator by wire or wirelessly, and the PLC controller 34 analyzes the received data of operating temperature, operating pressure and oxygen content, and controls the actuator to perform actions.

[0066] The coal catalytic gasification device includes high-pressure coal hopper 1, star feeder 2, fluidized bed reactor 3, steam generator 4, oxygen source 5, chi...

Embodiment 2

[0075] Using the monitoring method of the coal catalytic gasification safety monitoring system realized in embodiment 1, the detection mechanism detects the operating temperature, operating pressure and oxygen content data of the coal catalytic gasification device, and the detected operating temperature, operating pressure and oxygen content data The data is transmitted to the PLC controller 34; the PLC controller 34 analyzes the received operating temperature, operating pressure and oxygen content data, and controls the actuator to perform actions.

[0076] Preset the first temperature setting value, the second temperature setting value, the first pressure difference setting value, the second pressure difference setting value, the third pressure difference setting value, and the fourth pressure difference setting value in the PLC controller 34 The set value, the fifth set value of differential pressure, the sixth set value of differential pressure, the seventh set value of dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com